Hydraulic torque wrench

A torque wrench and hydraulic technology, applied in the field of torque wrench, can solve the problem of low torque output accuracy and achieve high torque output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

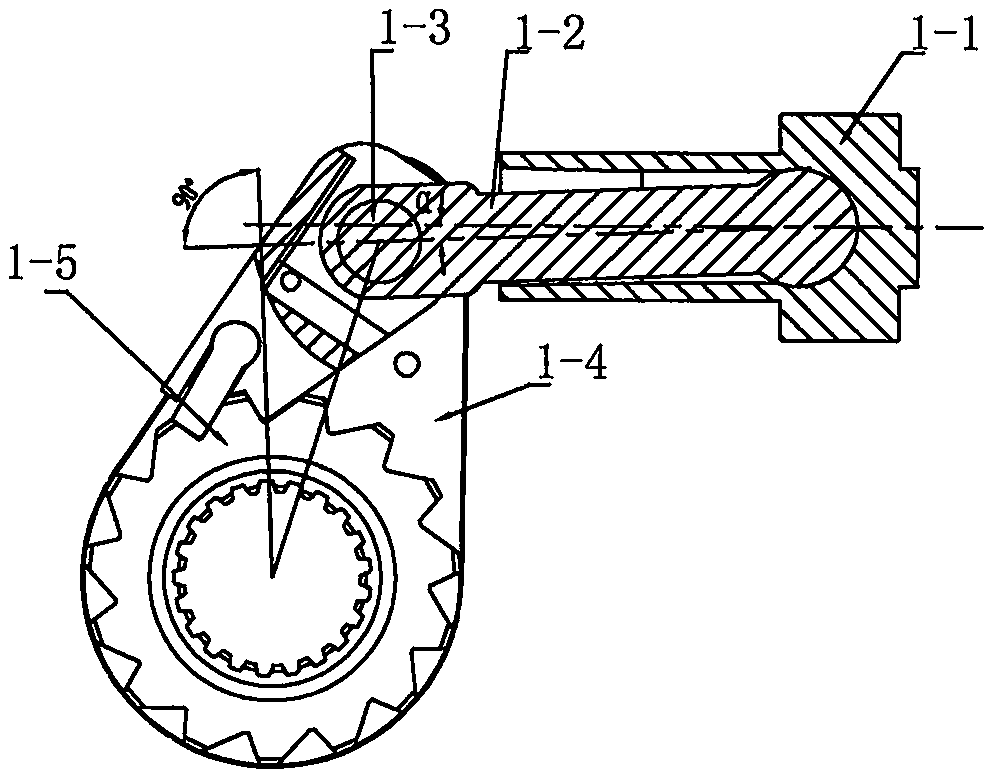

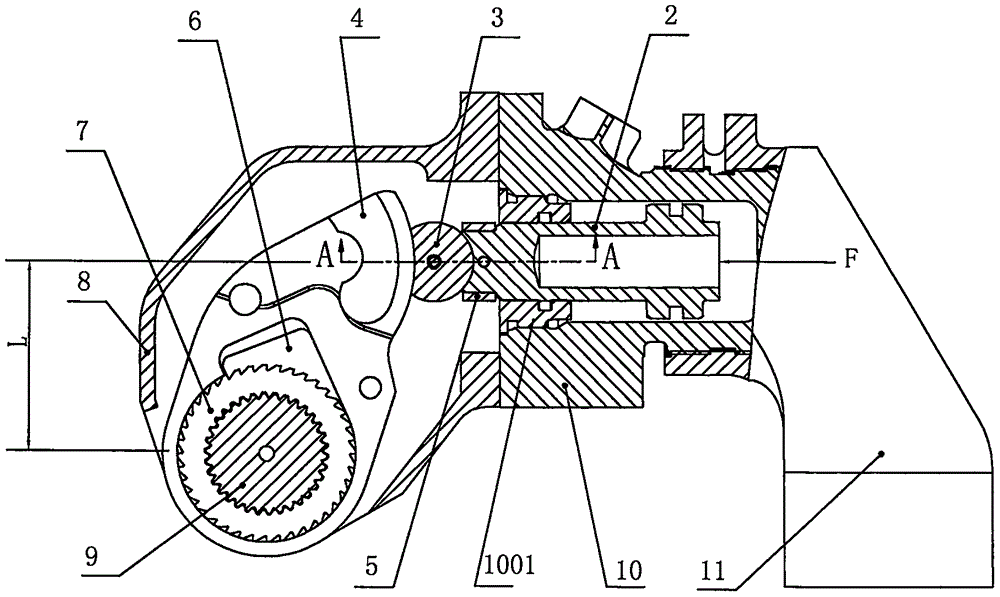

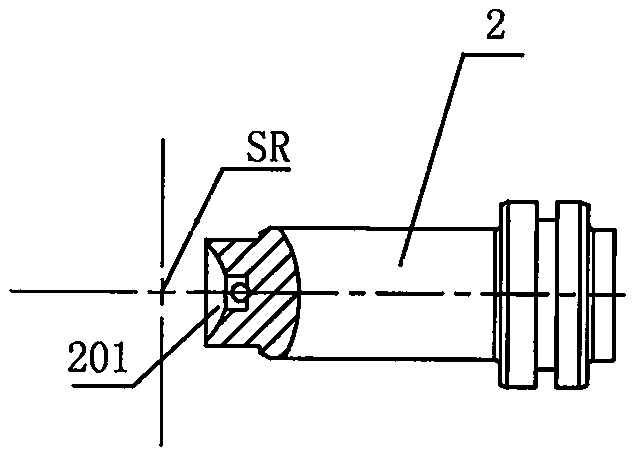

[0019] Such as Figure 2 to Figure 8 As shown, the present invention includes a ratchet mechanism and a loading mechanism. The loading mechanism includes a hydraulic cylinder 10 installed on a reaction arm 11 and a piston 2 of the hydraulic cylinder 10. The ratchet mechanism includes a drive plate 4, and the upper end of the drive plate 4 is a force end. , the lower end is the power end that engages with the ratchet 7 through the ratchet 6 and drives the ratchet 7 to rotate. The feature that is different from the prior art is: the end face of the head of the piston 2 protruding from the cylinder end cover 1001 is a spherical concave surface 201, the end face of the force-bearing end of the driving plate 4 is a longitudinal arc-shaped convex surface 401, and the piston 2 A spherical segmented rotating seat 3 is installed between the protruding end and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com