A plane milling-rolling compound device and a milling machine including the device

A composite device and plane milling technology, which is used in the field of metal cutting and post-treatment surface strengthening on the surface of parts, can solve the problems of increasing the machining cycle of parts and the unsatisfactory effect of post-treatment rolling, so as to improve processing efficiency, save processing time, The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

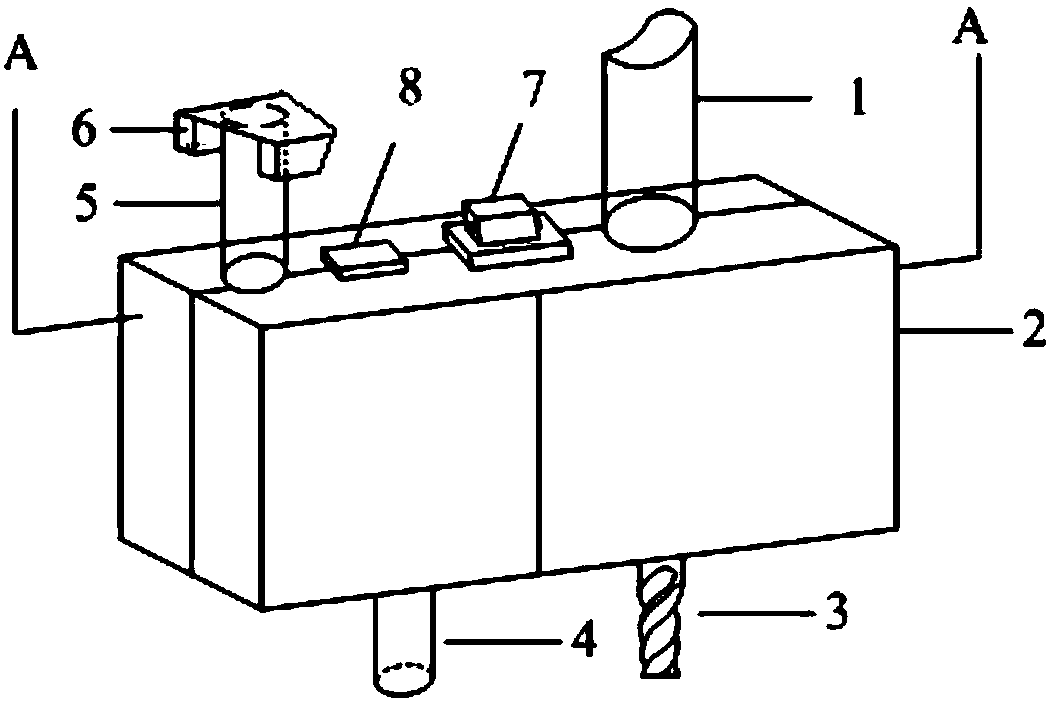

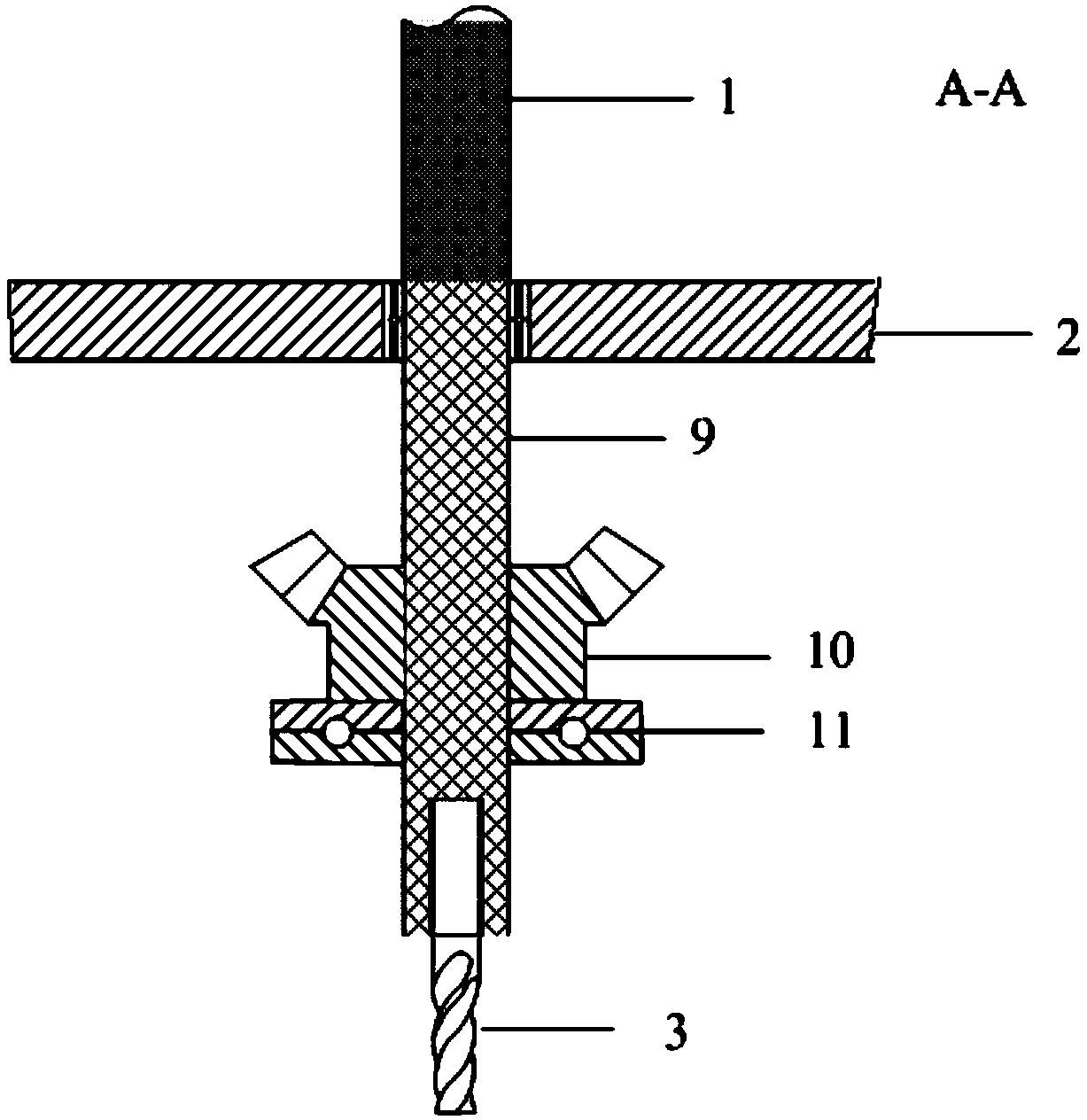

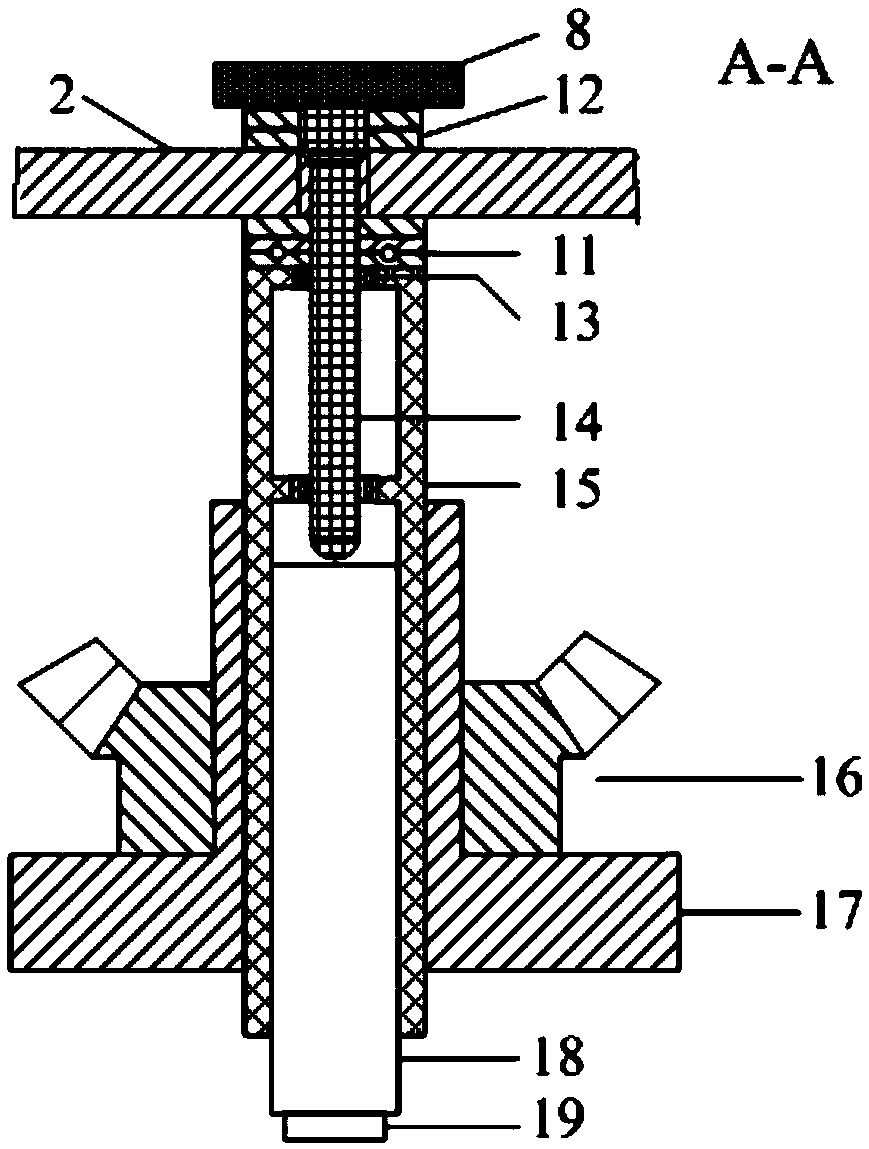

[0039] The overall structure of the plane milling-rolling composite device disclosed by the present invention is: comprising a shell, on which is provided a mounting handle for connecting with an external power device, the mounting handle is connected with the milling cutter body The cutter seat is coaxially connected, and the milling cutter body is installed on the cutter seat of the milling cutter body; the rotary motion of the cutter seat of the milling cutter body is transmitted to the cutter seat of the rolling cutter body through the transmission device, and the rolling The axis of the cutter seat of the cutter body is parallel to the axis of the cutter seat of the milling cutter body, and the cutter seat of the rolling cutter body also adjusts its axial displacement through a displacement adjustment device; the transmission device is also equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com