Automatic taking, feeding and molding mechanism for circular sheet applied to new-energy automobile

A new energy vehicle and automatic reclaiming technology, which is applied in the field of automatic retrieving and feeding forming mechanisms for circular thin plates for new energy vehicles, can solve problems such as troublesome installation, lower production efficiency, troublesome manual installation, etc., and achieve convenient feeding, The effect of improving processing efficiency and processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

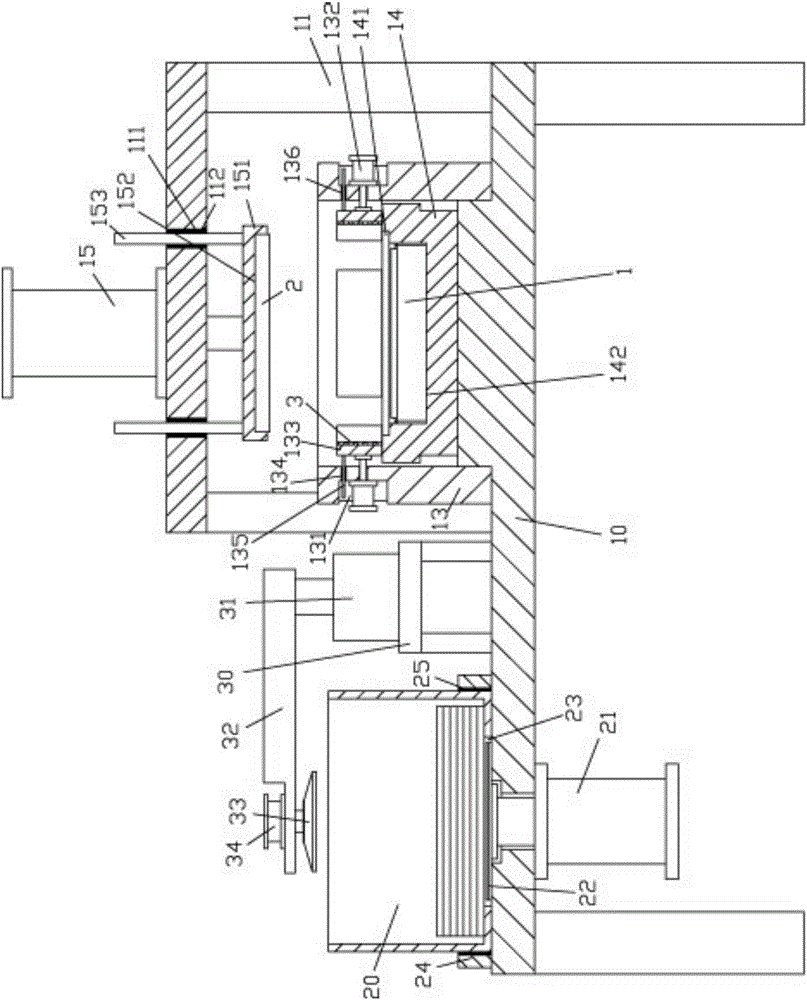

[0028] Examples, see e.g. Figures 1 to 4 As shown, a circular thin plate automatic feeding and forming mechanism for new energy vehicles includes a frame 10, an upper support frame 11 is fixed on the right side of the top plate of the frame 10, and the left side of the top plate of the frame 10 is placed There is a bucket 20, the top plate of the frame 10 between the bucket 20 and the upper support frame 11 is fixed with a rotary cylinder frame 30, the rotary cylinder 31 is fixed on the top surface of the rotary cylinder frame 30, and the end of the rotary shaft of the rotary cylinder 31 A rotating rod 32 is fixed on the top of the rotating rod 32, and a vacuum suction cup 33 is fixed on the bottom surface of the end of the rotating rod 32, and the vacuum suction cup 33 is directly above the barrel 20;

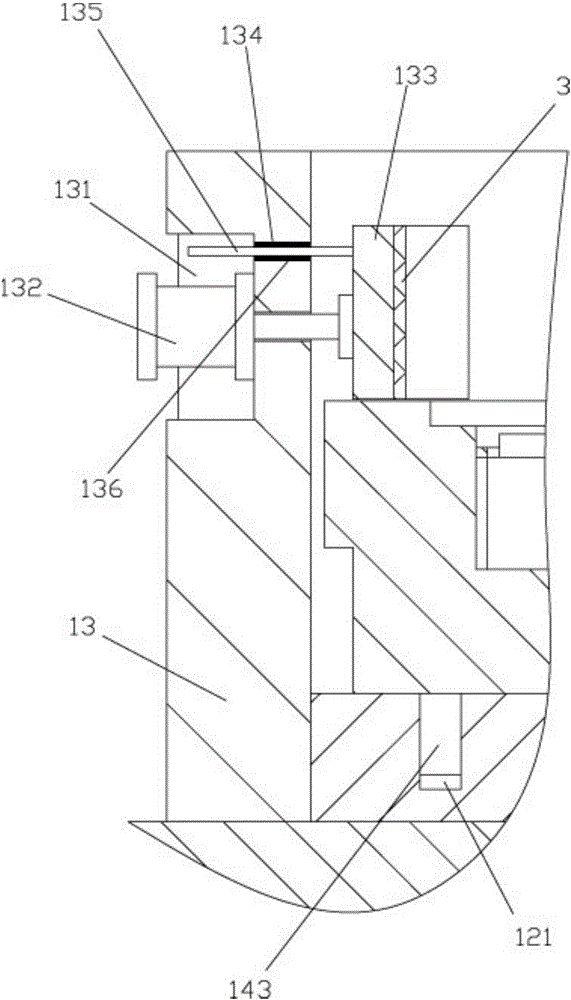

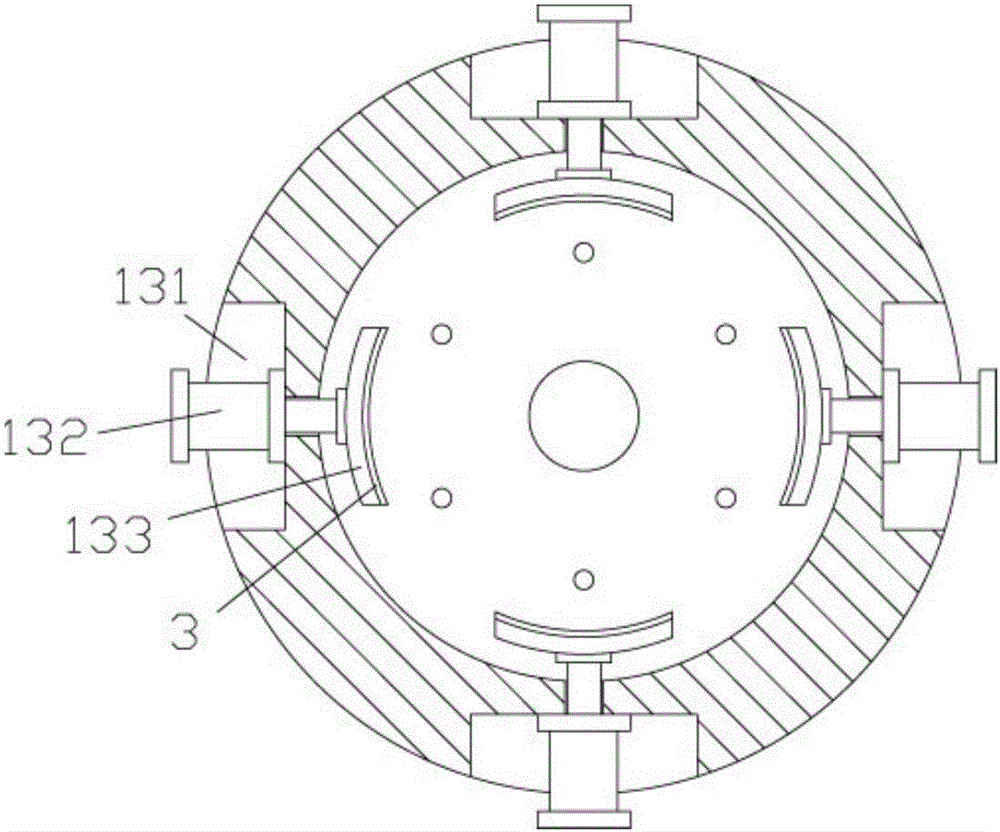

[0029] The middle part of the top plate of the frame 10 is formed with a connecting raised portion 12, and the top plate of the frame 10 at the outer side wall of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com