Fluorescent screen for X ray detection and preparation method thereof

An X-ray and fluorescent screen technology, applied in the field of X-ray detection, can solve the problems of high cost, complex preparation process, and no fluorescent screen preparation method, etc., and achieve the effects of low production cost, simple preparation process and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

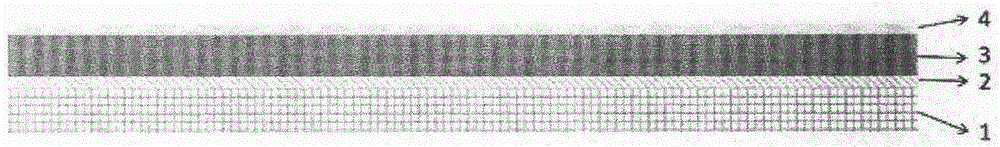

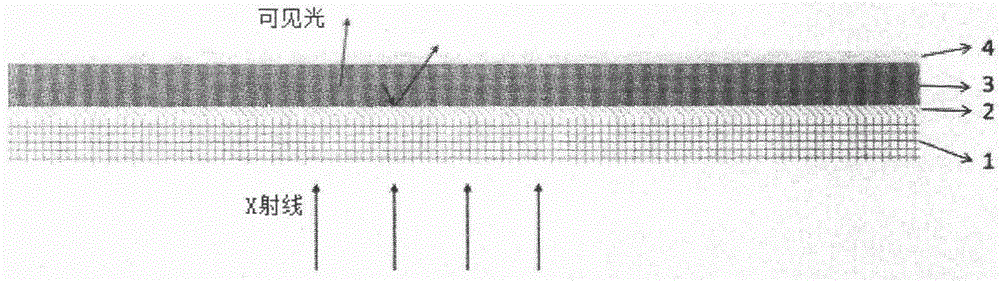

[0032] To prepare the above-mentioned fluorescent screen, it is first necessary to prepare the slurry for the reflective layer and the fluorescent layer. Fluorescent layer 3 uses gadolinium oxysulfide powder as phosphor, and its chemical formula is: (Gd 1-x-y Tb x Dy y ) 2 o 2 S, where x=0.005, y=0.005. The morphology of gadolinium oxysulfide powder is as follows image 3 As shown, the particle size of the powder is about 2-10μm, such as Figure 4 . Measure 30 g of gadolinium oxysulfide powder, 0.3 g of herring oil as a dispersant, 25 g of ethyl acetate as an organic solvent, 1.8 g of PVB as a binder, and 1.2 g of PEG-400 as a plasticizer, mix by ball milling, and the milling speed is 120 r / min, the time is 6h, and the slurry for preparing the fluorescent layer 3 is obtained. Select TiO2 as the powder for preparing the reflective layer 2, measure 10g TiO2, 0.1g herring oil as a dispersant, 35g ethyl acetate as a solvent, 0.6g PVB as a binder, and 0.4g PEG-400 as a pla...

Embodiment 2

[0035] The gadolinium oxysulfide powder used is the same as in Example 1. Measure 30g of gadolinium oxysulfide powder, 0.3g of herring oil as a dispersant, 10g of ethyl acetate and 10g of ethanol as an organic solvent, 1.8g of PVB as a binder, and 1.2g of PEG-400 as a plasticizer. 120r / min, ball milling time 4h, to obtain the slurry for preparing the fluorescent layer 3 . TiO2 is selected as the powder for preparing the reflective layer 2 . Measure 10g TiO2, 0.1g herring oil as dispersant, 12g ethyl acetate and 12g ethanol as solvent, 0.6g PVB as binder, 0.4g PEG-400 as plasticizer, mix by ball milling, ball milling speed is 120r / min, ball milling The time is 4 hours, and the slurry for preparing the reflective layer 2 is obtained.

[0036] After obtaining the slurry for preparing the fluorescent layer and the reflective layer, the steps for preparing the above-mentioned fluorescent screen are the same as in Example 1.

Embodiment 3

[0038] The gadolinium oxysulfide powder used is the same as in Example 1. Measure 30g of gadolinium oxysulfide powder, 0.3g of herring oil as a dispersant, 10g of ethyl acetate and 10g of ethanol as a solvent, 1.8g of PVB as a binder, 1.2g of PEG-400 as a plasticizer, ball milling, 120r / min , 4h, to obtain the slurry for preparing the fluorescent layer 3 . TiO2 is selected as the powder for preparing the reflective layer 2 . Measure 10g TiO2, 0.1g herring oil as dispersant, 10g ethyl acetate and 10g ethanol as organic solvent, 0.6g PVB as binder, 0.4g PEG-400 as plasticizer, mix by ball milling, the ball milling speed is 120r / min, The ball milling time was 4 hours, and the slurry for preparing the reflective layer 2 was obtained.

[0039] After obtaining the slurry for preparing the fluorescent layer and the reflective layer, the steps for preparing the above-mentioned fluorescent screen are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com