Spaceflight product assembly quality problem classification method based on big data analysis

A technology of quality problems and classification methods, applied in the intersection of quality management and data mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

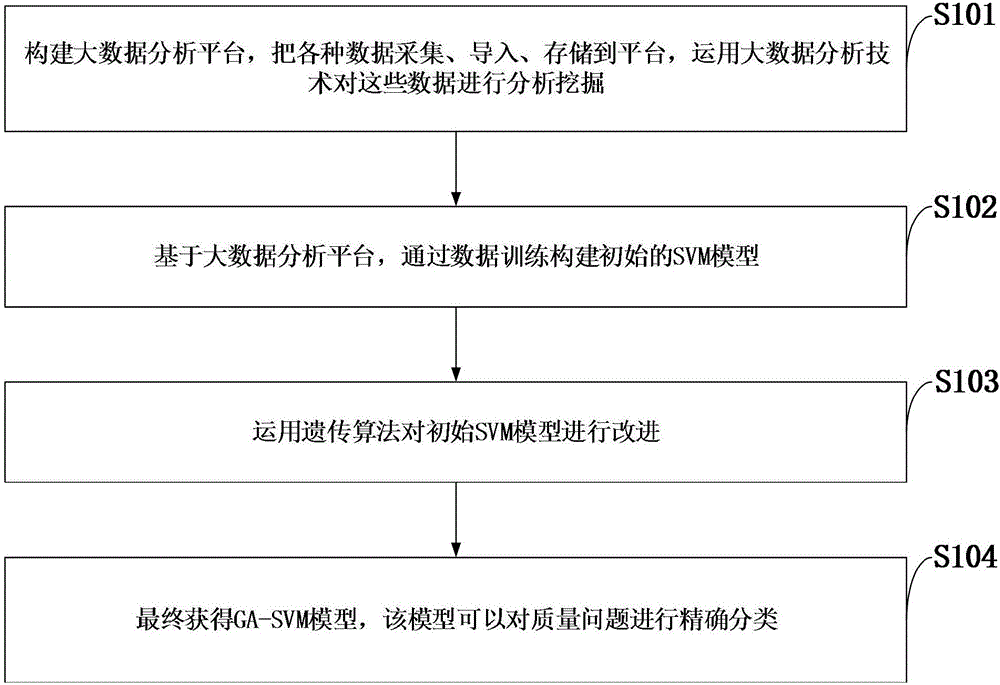

[0034] The method for classifying aerospace product assembly quality problems based on big data analysis in the embodiment of the present invention includes the following steps:

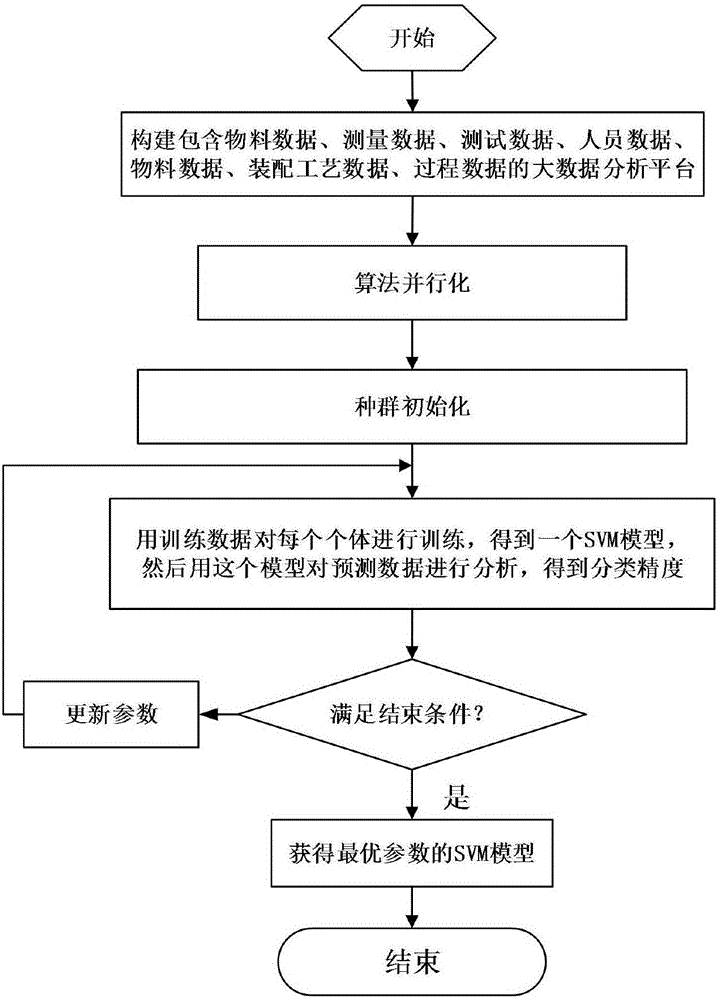

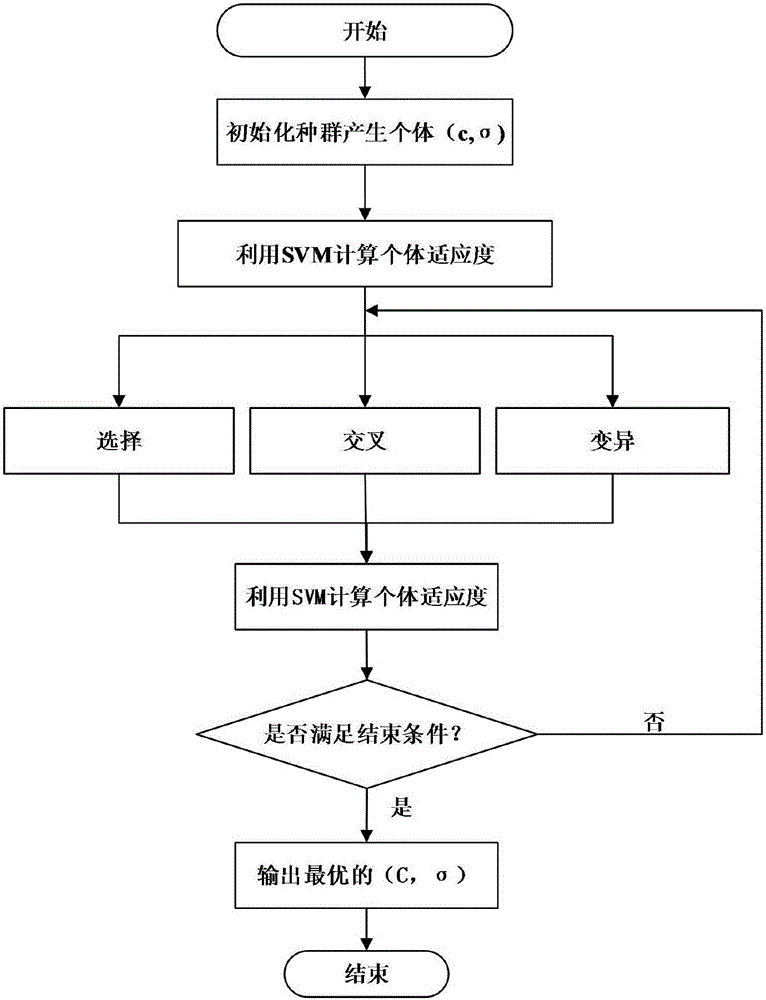

[0035] The basic idea of quality problem classification is as follows: figure 2 Shown: Build a big data analysis platform based on Hadoop, build an SVM model by combining influencing factors and historical quality problem data, use genetic algorithm to optimize the parameters of the SVM model, and use the classification accuracy of the SVM model as the fitness function in the genetic algorithm, If the classification accuracy of the SVM model meets the conditions or the genetic algebra meets the requirements, the parameters of the SVM model with the best classification accuracy are obtained, and the final GA-SVM model is also obtained; if the stop condition is not met, continue to optimize the model until it meets the requirements up to the request.

[0036] Step1: Build a big data analysis platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com