A sand control method for fine silt sand reservoir filling

A technology for fine silt sand and sand control, which is applied in earthwork drilling, wellbore/well components, instruments, etc. It can solve problems such as easy to break water layers and short sand control period, so as to ensure effectiveness, meet sand control requirements and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

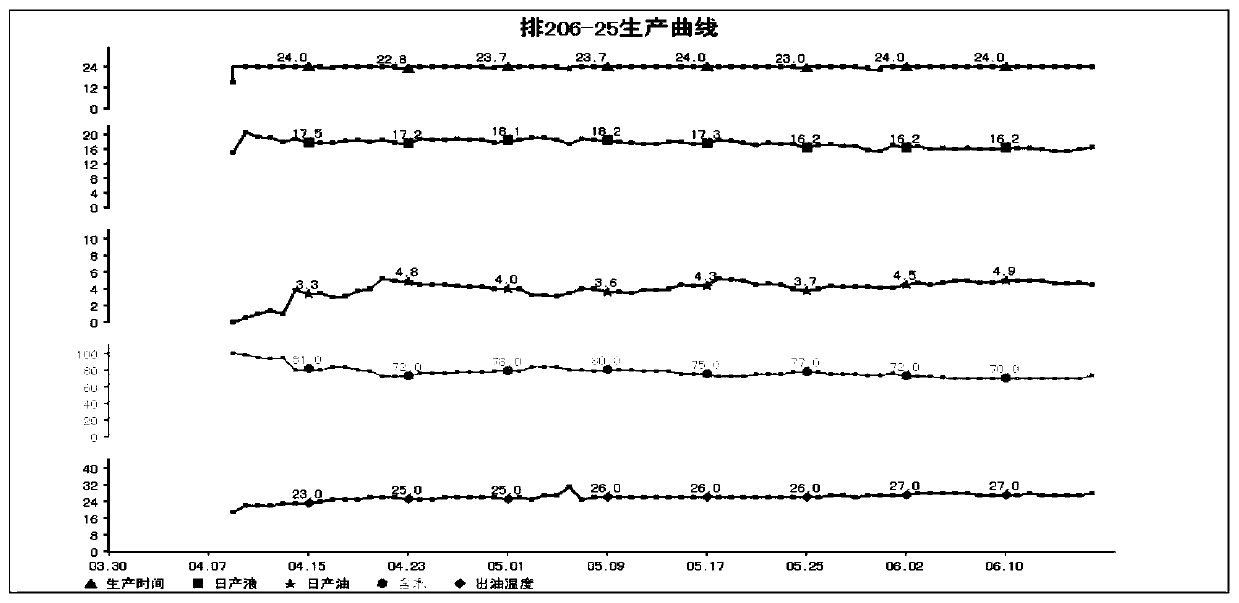

[0053] The fine silt sand oil layer filling sand control method of the present embodiment, for Pai 206-25 well, comprises the following steps:

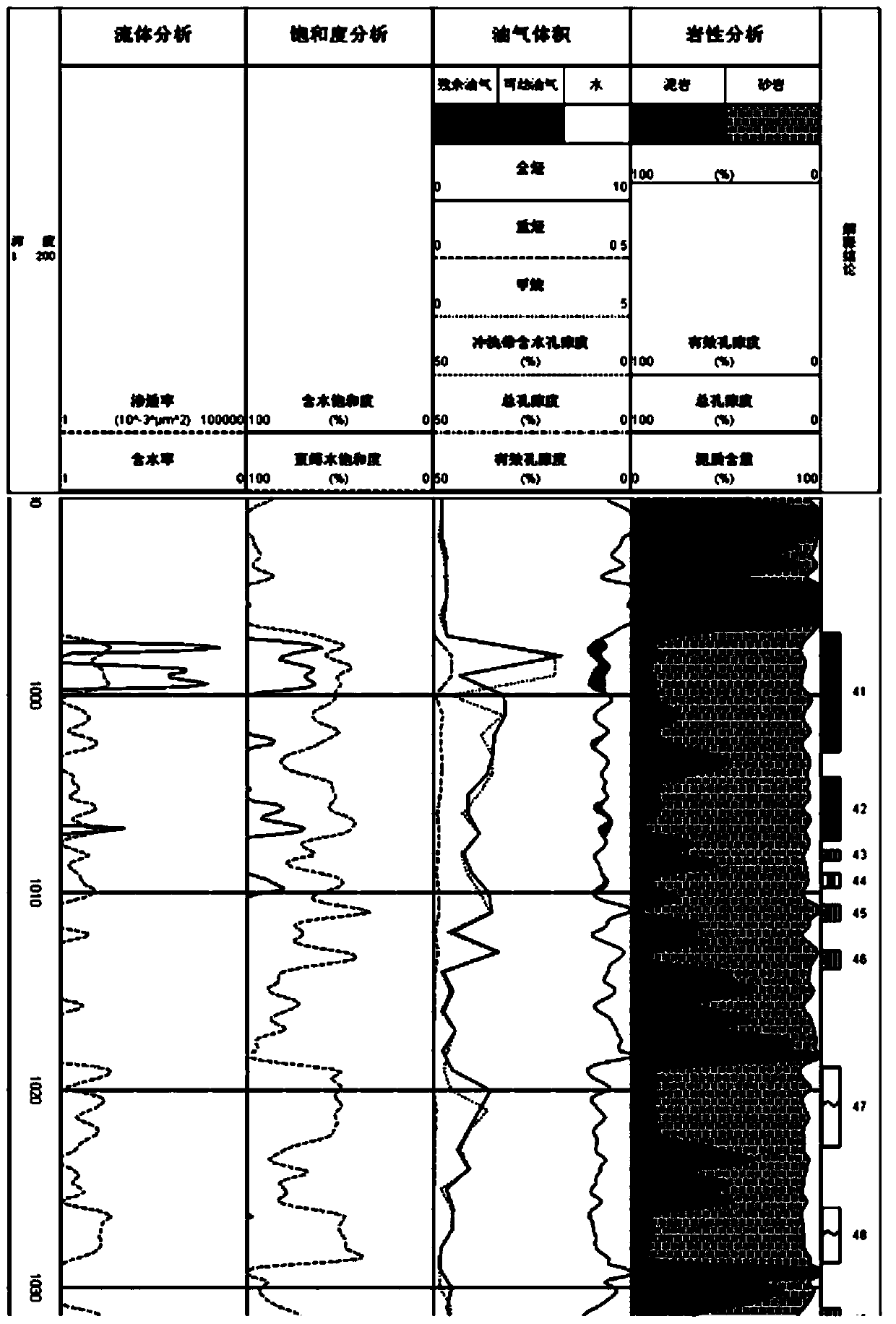

[0054] 1) According to image 3 , Figure 4 The well logging interpretation result map shows that the oil layer thickness H is 3m, and the rock porosity 10%, oil saturation S is 10%, rock permeability K is 1μm 2 , calculated to get Productivity coefficient = H × K = 3m·μm 2 ; Take the oil layer as the sand control layer;

[0055] Through the analysis of rock thin section test, it can be concluded that the sample of fine silt sandstone is gray-green, and the cementation type is basal cementation; Quality rock 10%, mudstone content 25%, mica 10%;

[0056] Fill the rock debris sample of the fine silt sand oil layer into the sand filling pipe, and measure the permeability of the sand control fluid to the rock debris in the sand filling pipe; the mass percentage composition of the sand control fluid used is: polymer thickener 0.5%,...

Embodiment 2

[0087] The fine silt sand reservoir filling sand control method of the present embodiment, for Chun 90 well, comprises the following steps:

[0088] 1) According to the result map of well logging interpretation, the oil layer thickness H is 8m, and the rock porosity 25%, oil saturation S is 25%, rock permeability K is 1μm 2 , calculated to get Productivity coefficient = H×K=8m·μm2; take this oil layer as sand control layer;

[0089] Fill the rock debris sample of the fine silt sand oil layer into the sand filling tube, and measure the permeability of the sand control fluid to the rock debris in the sand filling tube; the mass percentage composition of the sand control fluid used is: 0.5% guar gum, 3% KCl, NH 4 Cl 2%, the balance is water, and its permeability reduction value is 10%, which meets the requirements;

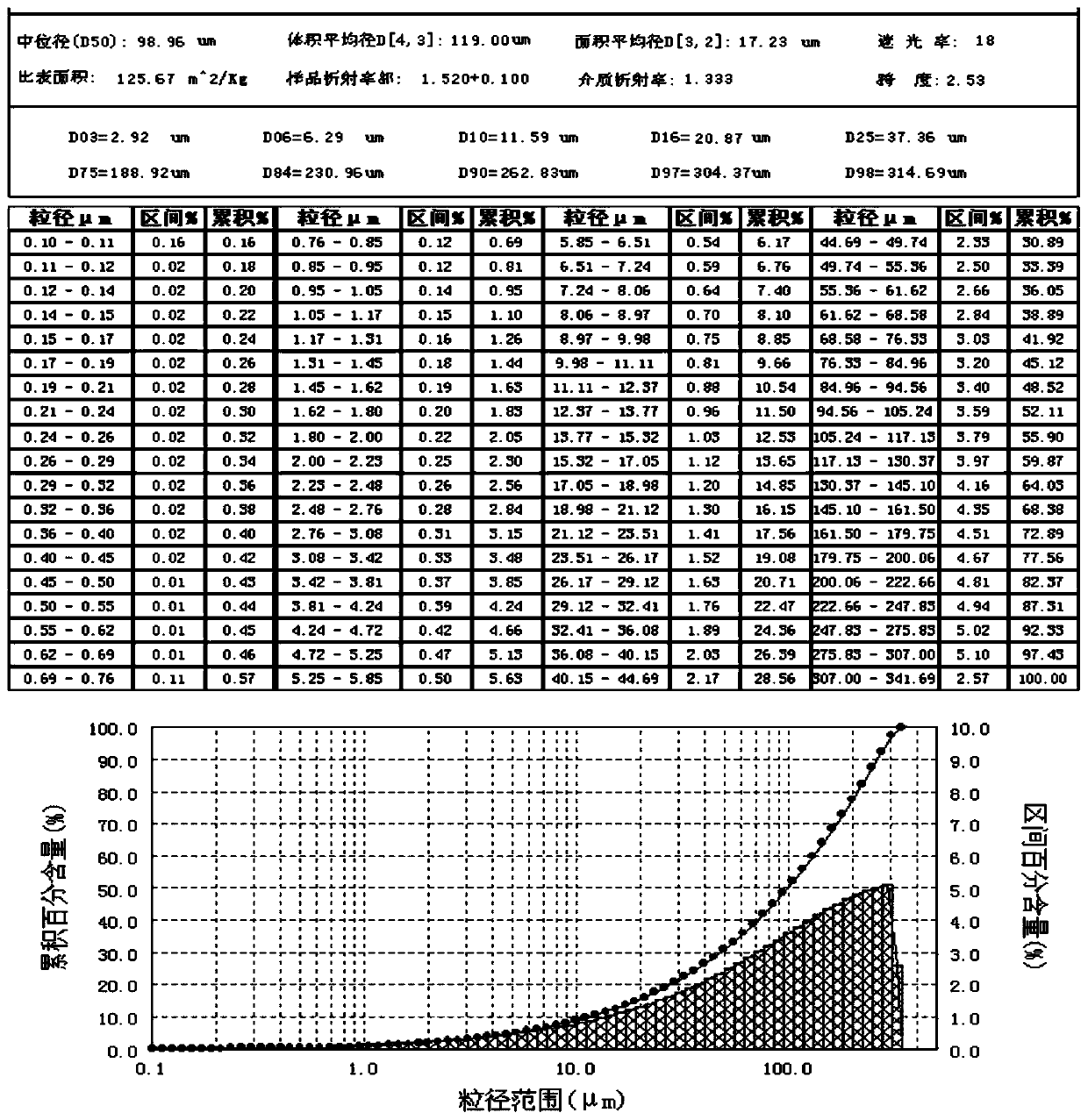

[0090] The D50 particle size of the formation rock in this well is 0.04mm;

[0091] 2) The interlayer rock core 3.5m below the water intake layer and with a natu...

Embodiment 3

[0116] The fine silt sand oil layer filling sand control method of the present embodiment, for Chun 110E well, comprises the following steps:

[0117] 1) According to the result map of well logging interpretation, the oil layer thickness H is 3.5m, and the rock porosity 15%, oil saturation S is 15%, rock permeability K is 1μm 2 , calculated to get Productivity coefficient = H × K = 3.5m·μm 2 ; Take the oil layer as the sand control layer;

[0118] Fill the rock debris sample of the fine silt sand oil layer into the sand filling tube, and measure the permeability of the sand control fluid to the rock debris in the sand filling tube; the mass percentage composition of the sand control fluid used is: 0.5% guar gum, 3% KCl, NH 4 Cl 2%, the balance is water, and its permeability reduction value is 10%, which meets the requirements;

[0119] The D50 particle size of the formation rock in this well is 0.06mm;

[0120] 2) The interlayer rock core 5m below the water intake layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com