Method for analyzing processability of raw dehydrated potato flour through Mixolab

A technology of raw potato powder and mixing test equipment, which is applied in the direction of material inspection, testing starch pollutants, testing food, etc., can solve problems such as starch gelatinization and protein denaturation, and achieve good reproducibility and wide adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

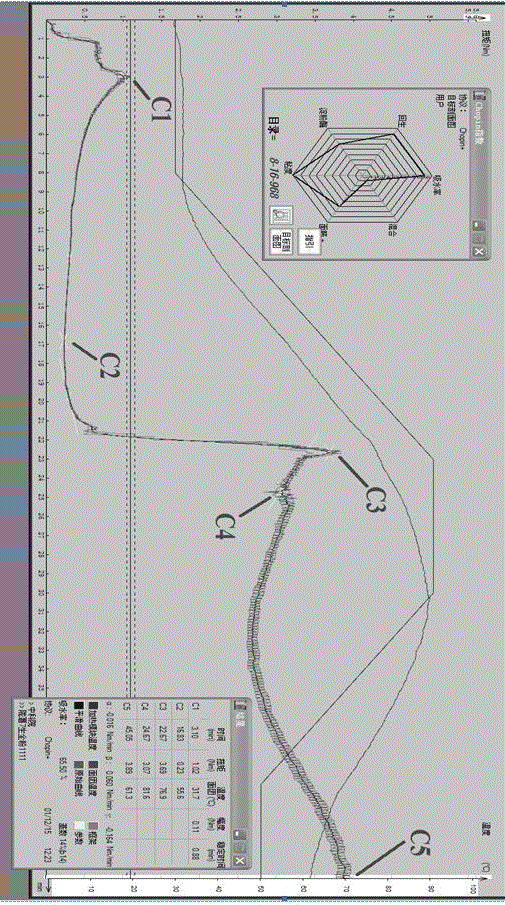

[0017] Example 1: Processing Performance Analysis of Vacuum Freeze Dried Potato Raw Whole Powder

[0018] Vacuum freeze-dried Longshu No. 7 potato chips (diced) were crushed and passed through a 110-mesh sieve to analyze their moisture content. Select the chopin+ experimental protocol, enter the water content of the sample and the estimated hydration rate value of the flour in the software, select a hydration rate benchmark (14% moisture basis) as the working condition for the software to calculate the sample weight, and calculate it according to the Mixolab software program Weight, take the vacuum freeze-dried Longshu No. 7 raw potato raw whole powder sample with a balance.

[0019] Put the kneading bowl into the kneading bin and cover with a cover. Click the "Start" button on the software, use the Mixolab special funnel to pour the weighed sample into the kneading bowl, and place the water injection nozzle at the water inlet of the kneading bowl cover. The time to complete...

Embodiment 2

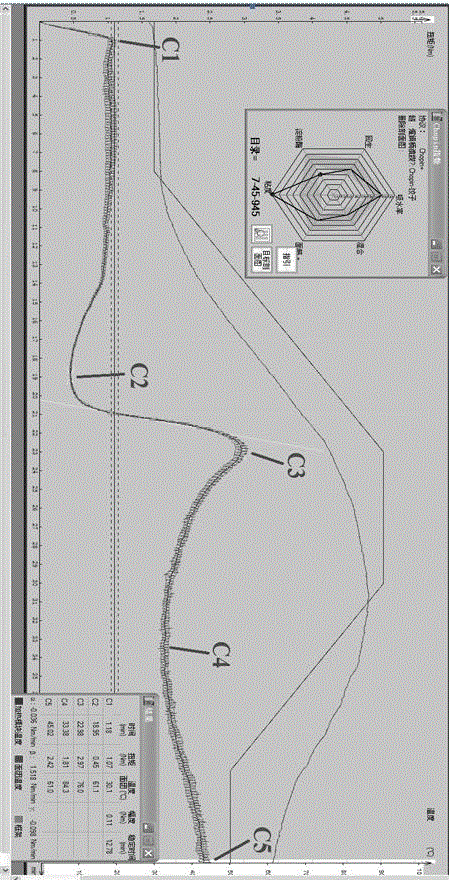

[0022]Example 2: Effect of Gluten Flour on the Processing Performance of Longshu No. 3 Potato Raw Whole Flour

[0023] Longshu No. 3 potato slices dried under vacuum at 60°C were crushed and passed through a 110-mesh sieve, 5% gluten was added, and the moisture content was analyzed after mixing. The chopin+ experimental protocol was used to analyze the processing performance of Longshu No. 3 raw potato flour before and after adding gluten, and the analysis steps were the same as in Example 1. See the graph of the experimental results figure 2 .

[0024] figure 2 The analysis results showed that gluten can improve the stability of potato dough, but the high viscosity of the dough after heating needs to be solved by adding other food additives or enzymes: in the initial stage of mixing, the dough torque reached C1 at 1.18 min and was very stable until It started to decrease after 14 minutes. This is because the gluten protein contained in the gluten flour was mixed with wat...

Embodiment 3

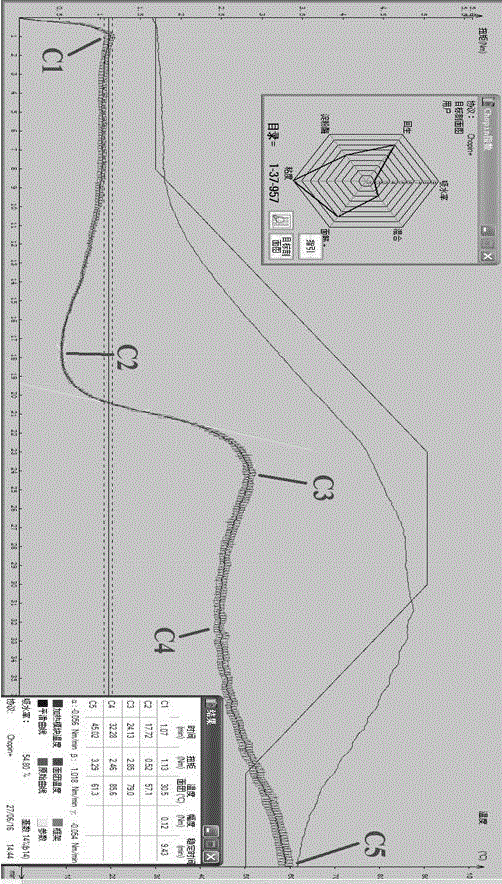

[0026] Example 3: Processing performance analysis of raw whole potato powder partially replacing flour

[0027] Dingshu No. 4 raw potato powder dried at 60°C in an electric blast drying oven was passed through a 110-mesh sieve, and the raw potato powder was used to replace 30% wheat flour, and the moisture content was measured after mixing. The chopin+ experimental protocol was used to analyze the processing performance of whole potato flour partially substituted for wheat flour, and the analysis steps were the same as in Example 1. See the graph of the experimental results image 3 .

[0028] image 3 The results of the analysis showed that the partial substitution of whole potato flour for wheat flour changed the processing performance of wheat flour: the torque C1 value after dough formation can be relatively stable, indicating that the addition of 30% raw potato flour did not cause too much damage to the gluten content of the dough. The dough can basically be maintained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com