Detection device for composite steel belt of elevator

A detection device and technology of composite steel are applied in the field of elevator traction components to achieve the effects of convenient operation, ensuring operation safety and eliminating fault risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

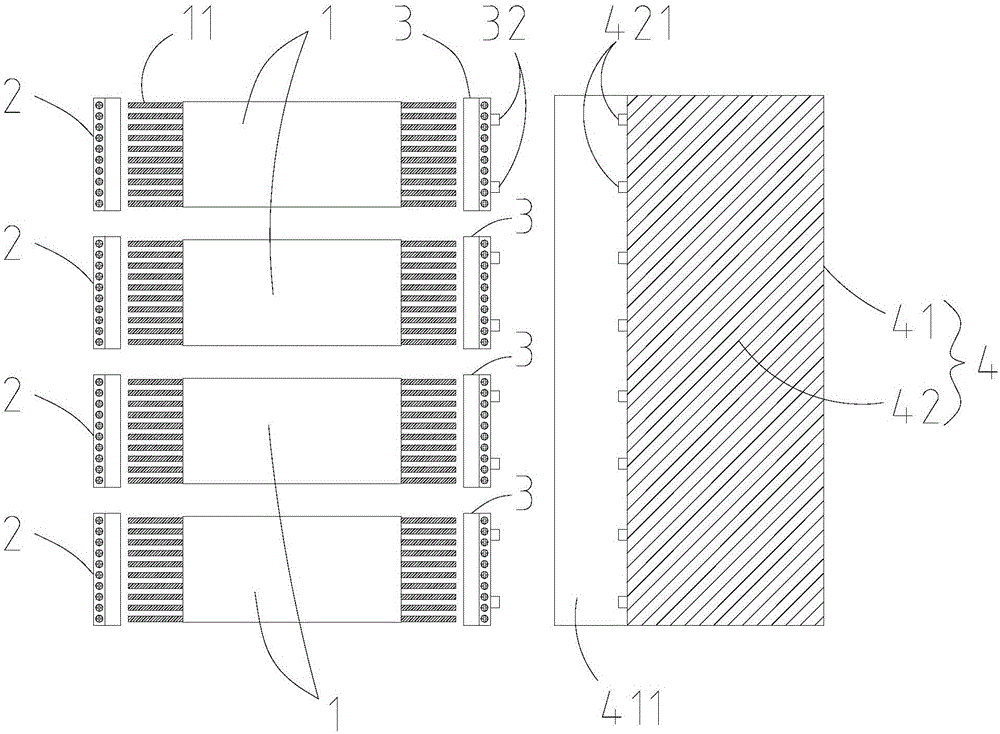

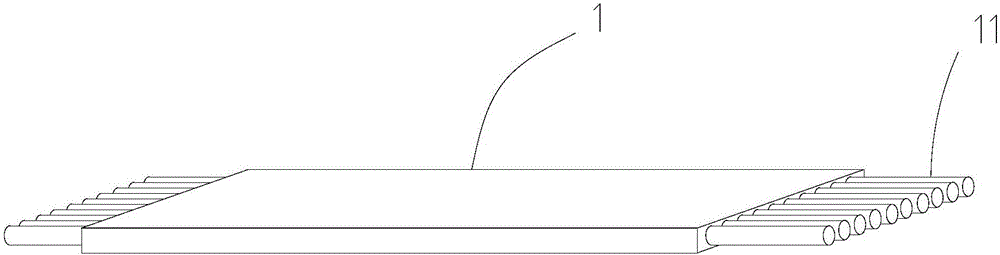

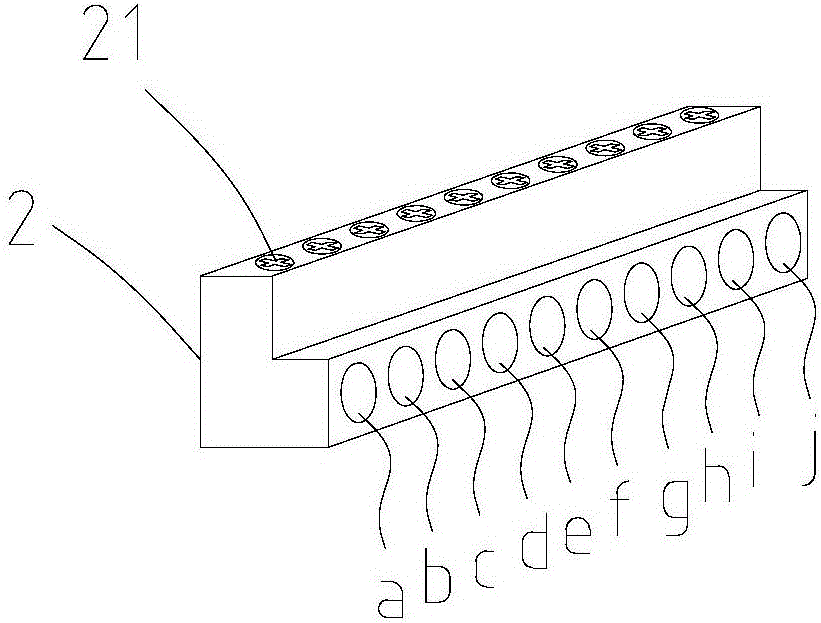

[0025] see Figures 1 to 4 , a detection device for an elevator composite steel belt, comprising a first electrical connector 2 , a second electrical connector 3 and an electrical signal analysis device 4 . Among them, there are four first electrical connectors 2 and four second electrical connectors 3 , and one first electrical connector 2 and one second electrical connector 3 can be used to connect a composite steel strip 1 . Before the detection of the composite steel strip 1 , the non-metallic wrapping layers at the first and last ends need to be stripped off to expose the first and the ends of the multi-strand steel core 11 . The first end of each steel core 11 in the composite steel strip 1 is electrically connected to the first electrical connector 2 , and the second electrical connector 3 at the end is respectively electrically connected. Each second electrical connector 3 is provided with two connection contacts 32 , and the two connection contacts 32 can be correspo...

Embodiment 2

[0035] Such as image 3 , 4As shown in and 6, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the first potential connection points on the first electrical connector 2 are connected in groups of two, and the second electrical connector 3 includes A second potential connection point is connected to one of the connection contacts 32 on the second electrical connector 3, wherein another second potential connection point is connected to another connection contact 32 on the second electrical connector 3, and the rest The second potential connection points are connected in pairs, and all the steel cores 11 of the same composite steel strip 1 are electrically connected to all the first potential connection points and all the second potential connection points respectively, and then connected end to end to form a pure series circuit. Specifically, in this embodiment, on the first electrical connector 2, a is c...

Embodiment 3

[0037] Such as image 3 , 4 As shown in and 7, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that all the second electrical connection points k, l, m, n, o, p, q of the second electrical connector 3 of this embodiment , r, s, t are equipotentially connected to one of the connection contacts 32, and all the first points of the first electrical connector 2 are connected to points a, b, c, d, e, f, g, h, i, After the equipotential connection, it is connected with another connection contact 32 through the electrical connector 5, and all the steel cores 11 of the same composite steel strip 1 are respectively electrically connected with all the first potential connection points and all the second potential connection points to form a pure parallel circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com