Two-time upside-entrainment burner

A burner and air inlet technology, applied in the field of cookers, can solve the problems of no protection device, complicated manufacturing and assembly, low combustion efficiency, etc., and achieve the effects of simple manufacturing and assembly, prevention of gas leakage, and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further explained in conjunction with the accompanying drawings.

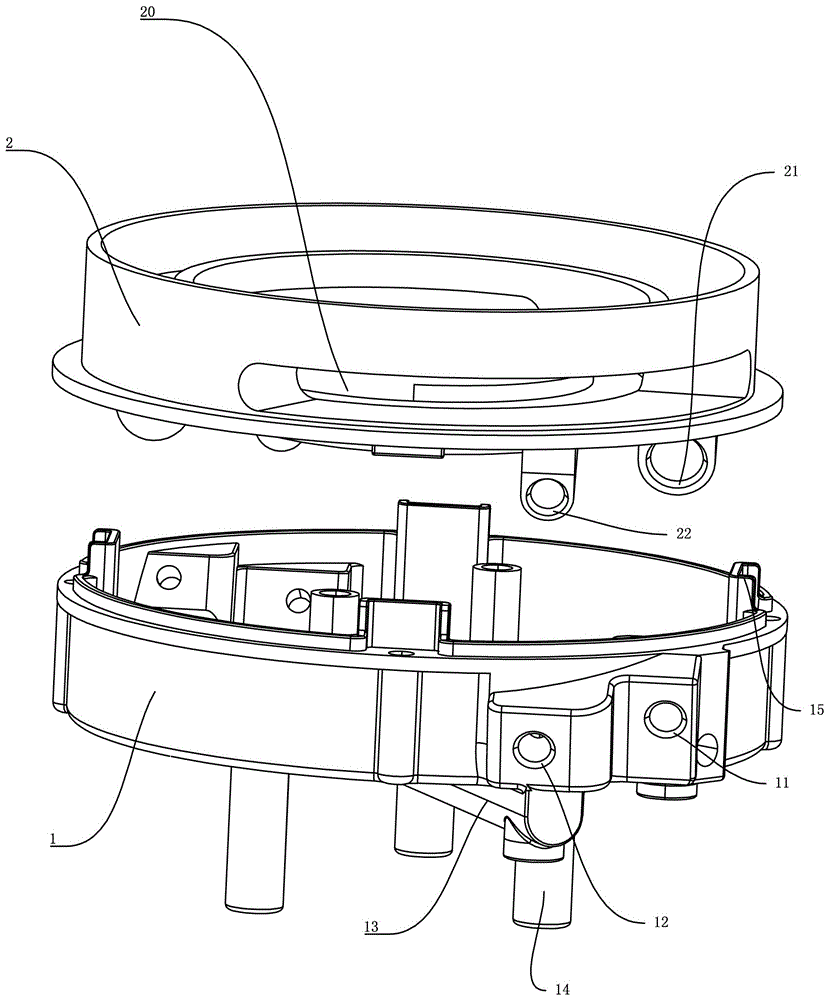

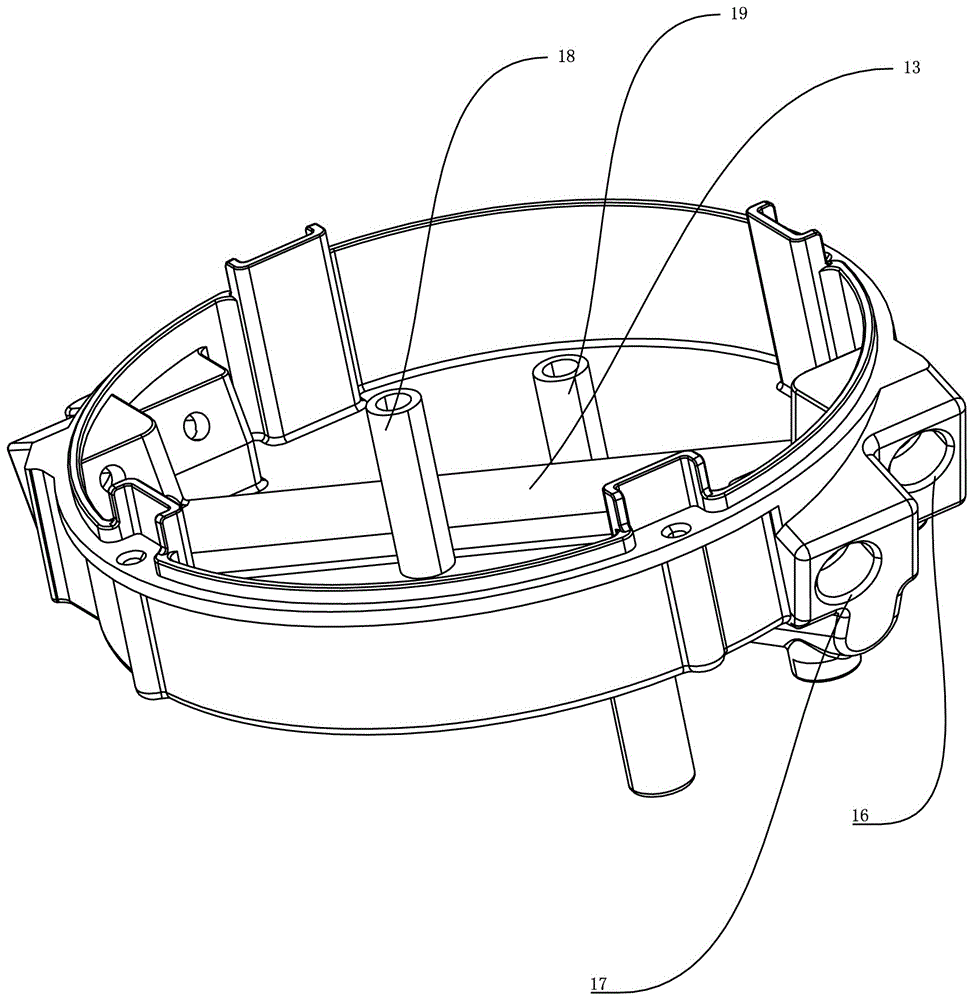

[0027] see Figure 1 to Figure 6 A secondary upward air intake burner shown includes a base 1 and a bracket 2. The base 1 is provided with supporting four pillars 15 for supporting the bracket 2. A primary air inlet 10 is formed between two adjacent pillars 15. The base 1 and the support 2 are connected through the pillar 15, which reduces the contact area between the base 1 and the support 2, thereby reducing the heat conducted from the support 2 to the base 1 when the burner is working. Each support 15 is provided with a slot, and the bracket 2 is correspondingly provided with four buckles 28, and the buckles 28 and the slots are closely matched to prevent the bracket 2 and the base 1 from rotating relative to each other.

[0028] The base 1 is obliquely provided with a first outer layer air inlet nozzle 11, a first inner layer air inlet nozzle 12, a second outer layer air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com