Integrating multi-functional lightweight thermostat housing and using method thereof

A thermostat and lightweight technology, which is applied in the direction of engine cooling, machine/engine, coolant flow control, etc., can solve the problems of increasing the overall space of the thermostat, occupying a lot of space, increasing costs, etc., and achieving structural Compact, small footprint, the effect of reducing the overall space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

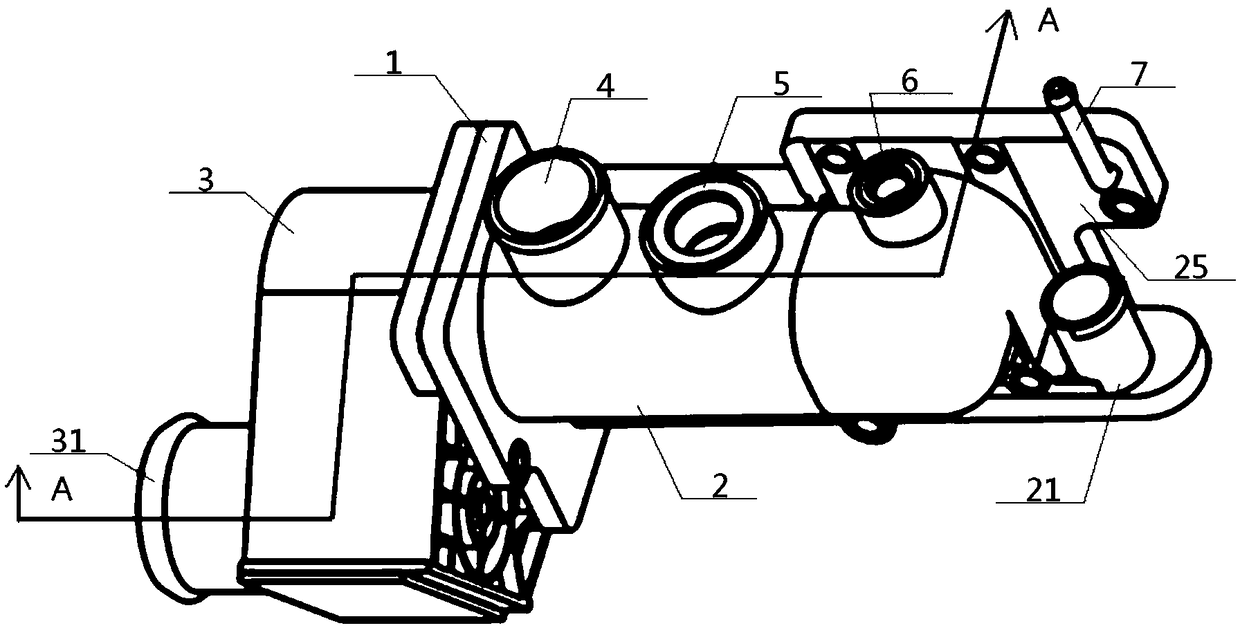

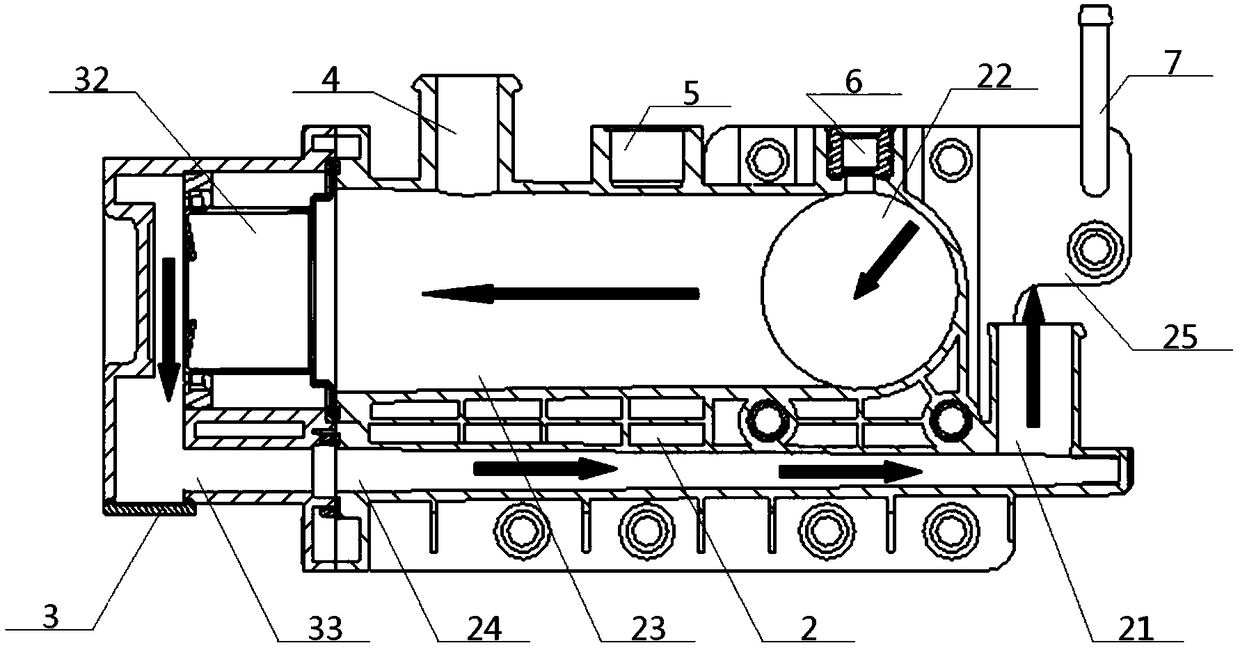

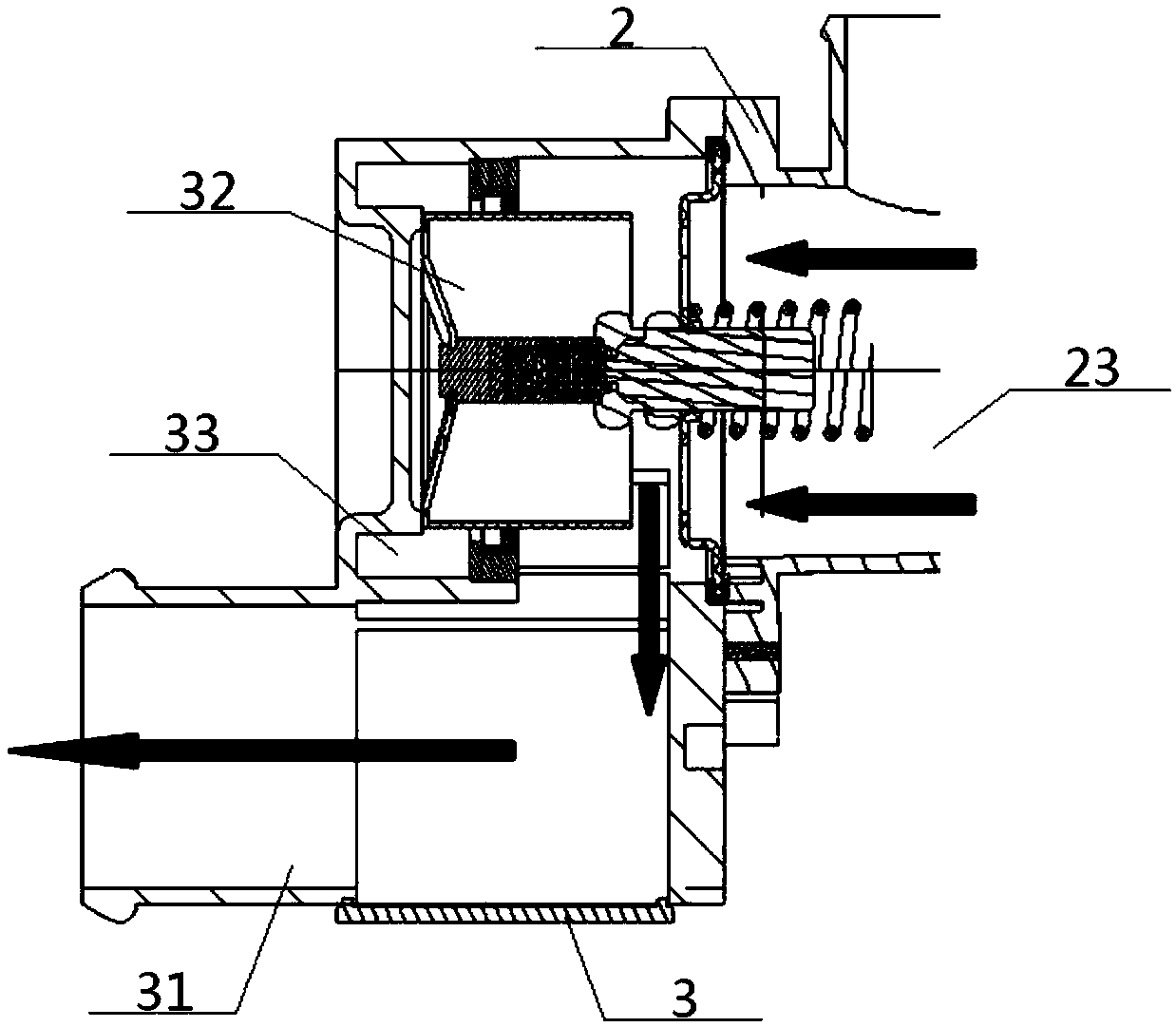

[0044] see Figure 1 to Figure 4 , an integrated multi-functional lightweight thermostat housing, including a thermostat chamber 2 and a thermostat chamber cover 3 with an interconnected structure, the thermostat chamber 2 is provided with a small circulation interface 21 and a water inlet 22. A large circulation interface 31 is provided on the thermostat chamber cover 3, a thermostat 32 is provided in the inner cover cavity 33 of the thermostat chamber cover 3 near the thermostat chamber 2, and a small circulation interface 21, water inlet 22 is located on the same side of the thermostat 32, and the large circulation interface 31 is located on the other side of the thermostat 32; the thermostat chamber 2 is provided with a water inlet cavity 23 and a built-in small circulation passage 24, and the water inlet 22 , the water inlet chamber 23, the cover chamber 33, the built-in small circulation channel 24, and the small circulation interface 21 are connected in sequence; the wa...

Embodiment 2

[0049] Basic content is the same as embodiment 1, the difference is:

[0050] The back of the thermostat chamber 2 is provided with a water inlet cover 25 integral with it, and a water inlet 22 is provided in the middle of the water inlet cover 25 . The water inlet cover 25 is provided with a degassing joint 7 . The top of the thermostat chamber 2 is provided with a water return port 4 communicating with the water inlet chamber 23, a water intake 5, and a temperature sensor interface 6. The water intake 5 is located between the water return port 4 and the temperature sensor interface 6, and the return The water outlet 4 is arranged near the thermostat 32, and the temperature sensor interface 6 is arranged near the water inlet 22.

Embodiment 3

[0052] Basic content is the same as embodiment 1, the difference is:

[0053] The manufacturing materials of the thermostat chamber 2 and the thermostat chamber cover 3 are engineering plastics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com