Double wall outer ring structure of a gas turbine turbine

A gas turbine, double-wall technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as aerodynamic losses, and achieve the effects of reducing aerodynamic losses, reducing air-conditioning volume, and increasing the density of flow ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

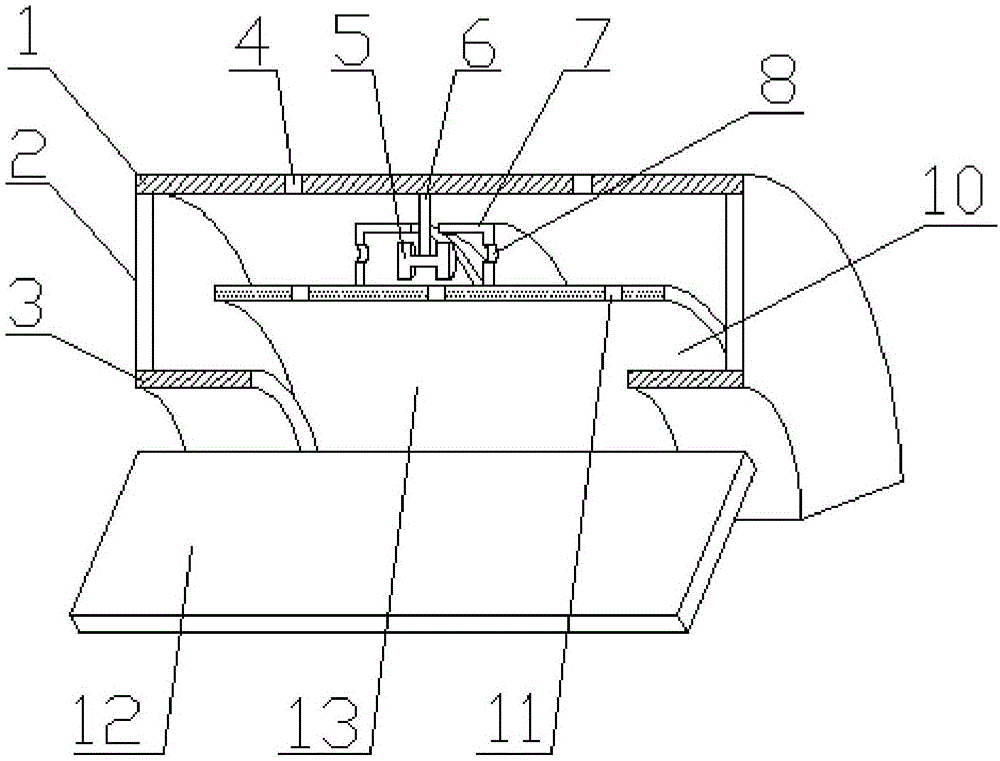

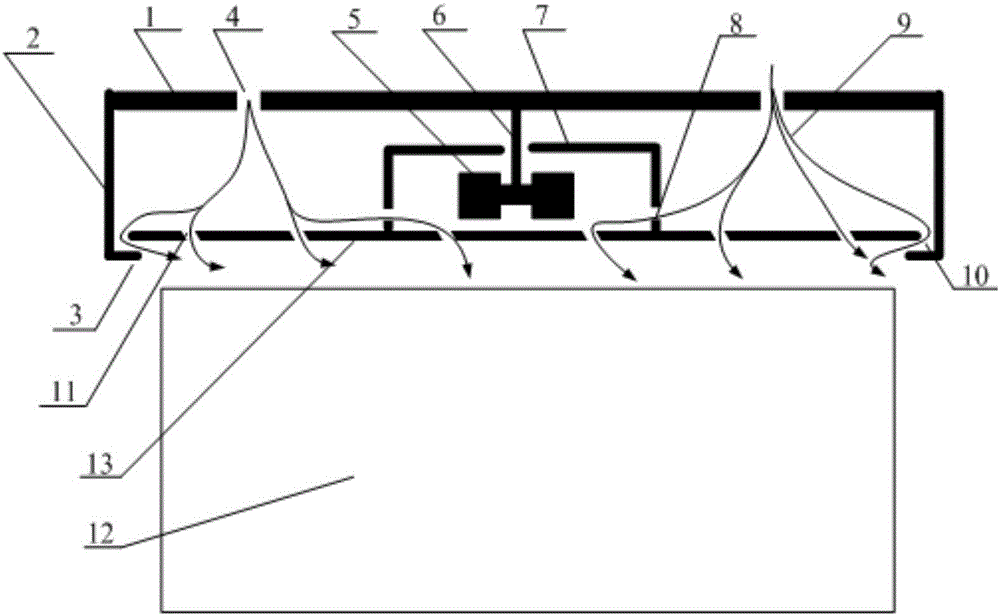

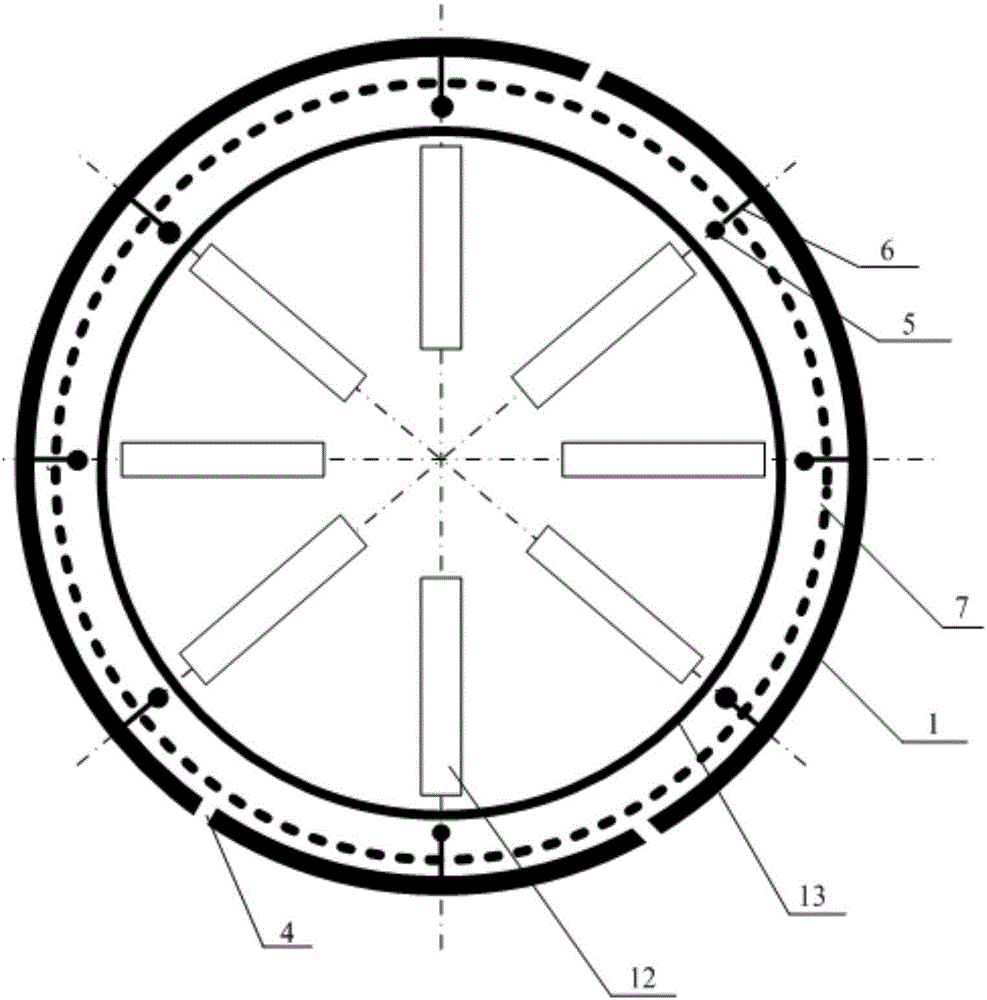

[0022] Embodiment 1: The axial chord length of the blade is 40mm. The axial inner length of the outer wall of the outer ring (the length between the two side walls) is 50mm, the height of the side wall is 8mm, the axial length of the support is 4mm, the diameter of the impact hole is 0.8mm, and there are two rows of impact holes, 30 in each row, evenly arranged , 6 bearings and their connecting rods, arranged evenly. The axial length of the inner wall is 46mm, the radius of rotation of the inner wall is 0.3m, one row of air film holes in the bearing cavity, two rows of air film holes outside the bearing cavity, one row on each side of the bearing cavity, 30 film holes for each exhaust, and the diameter of the air film holes 0.5mm, the height of the bearing cavity is 4mm, and the axial length is 20mm. Impact hole 85 degrees. The radius of the inner wall is greater than the radius of the support edge, the inner wall is located on the support edge, and the rotation speed of the...

Embodiment 2

[0024] Embodiment 2: The axial chord length of the blade is 60 mm. The axial inner length of the outer wall of the outer ring (the length between the two side walls) is 70mm, the height of the side wall is 10mm, the axial length of the support is 5mm, the diameter of the impact hole is 1mm, and there are two rows of impact holes, 50 in each row, evenly arranged. There are 16 bearings and connecting rods arranged evenly. The axial length of the inner wall is 68mm, the rotation radius of the inner wall is 0.5m, there are 2 rows of air film holes in the bearing cavity, 4 rows of air film holes outside the bearing cavity, 2 rows on each side of the bearing cavity, 40 film holes for each exhaust, and the diameter of the air film holes 0.5mm, the height of the bearing cavity is 5mm, and the axial length is 30mm. Impact hole 60 degrees. The radius of the inner wall is larger than the radius of the support edge, the inner wall is located on the support edge, and the speed of the inn...

Embodiment 3

[0026] Embodiment 3: The axial chord length of the blade is 120 mm. The axial inner length of the outer wall of the outer ring (the length between the two side walls) is 140mm, the height of the side wall is 20mm, the axial length of the support is 10mm, the diameter of the impact hole is 1.2mm, and there are two rows of impact holes, 40 in each row, evenly arranged , 30 bearings and connecting rods, evenly arranged. The axial length of the inner wall is 136mm, the radius of rotation of the inner wall is 1m, there are 2 rows of air film holes in the bearing cavity, 4 rows of air film holes outside the bearing cavity, 2 rows in each of two bearing chambers, 40 film holes for each exhaust, and the diameter of the air film holes is 0.8 mm, the height of the bearing cavity is 8mm, and the axial length is 50mm. Impact hole 80 degrees. The radius of the inner wall is greater than the radius of the support edge, the inner wall is located on the support edge, and the speed of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com