Construction method of stone aluminum honeycomb composite panel ceiling based on t-shaped and z-shaped pendants

A technology of honeycomb composite board and construction method, which is applied in the direction of ceiling, building components, buildings, etc., can solve the problems of poor quality of stone aluminum honeycomb composite board ceiling, random construction operation, complicated construction process, etc., and achieves easy guarantee of processing quality and installation Easy and fast installation for quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

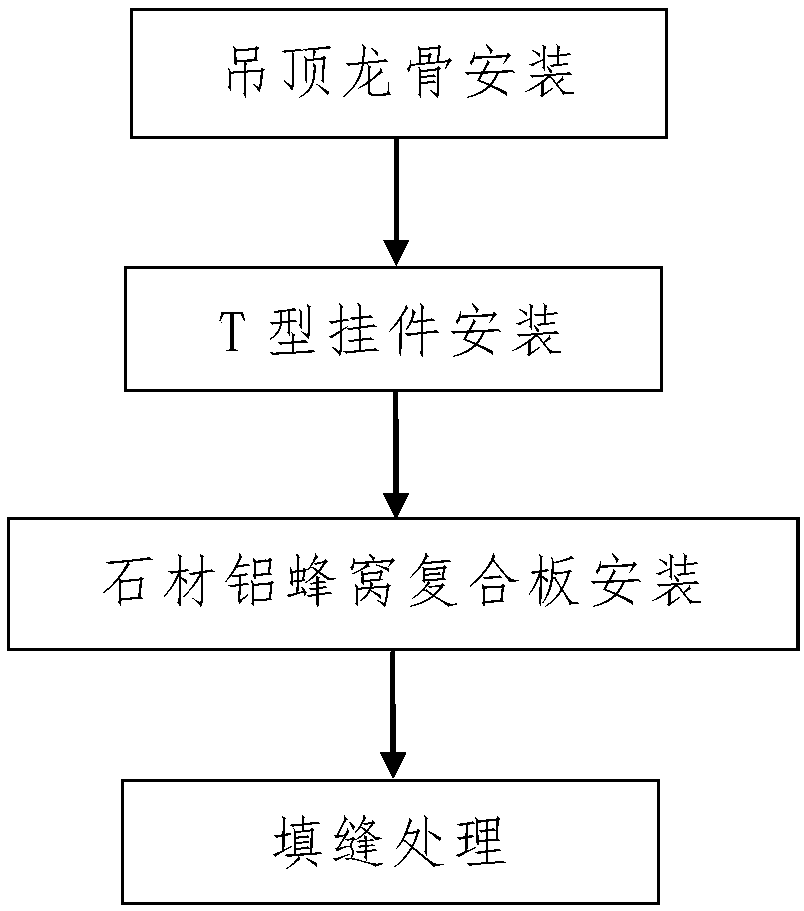

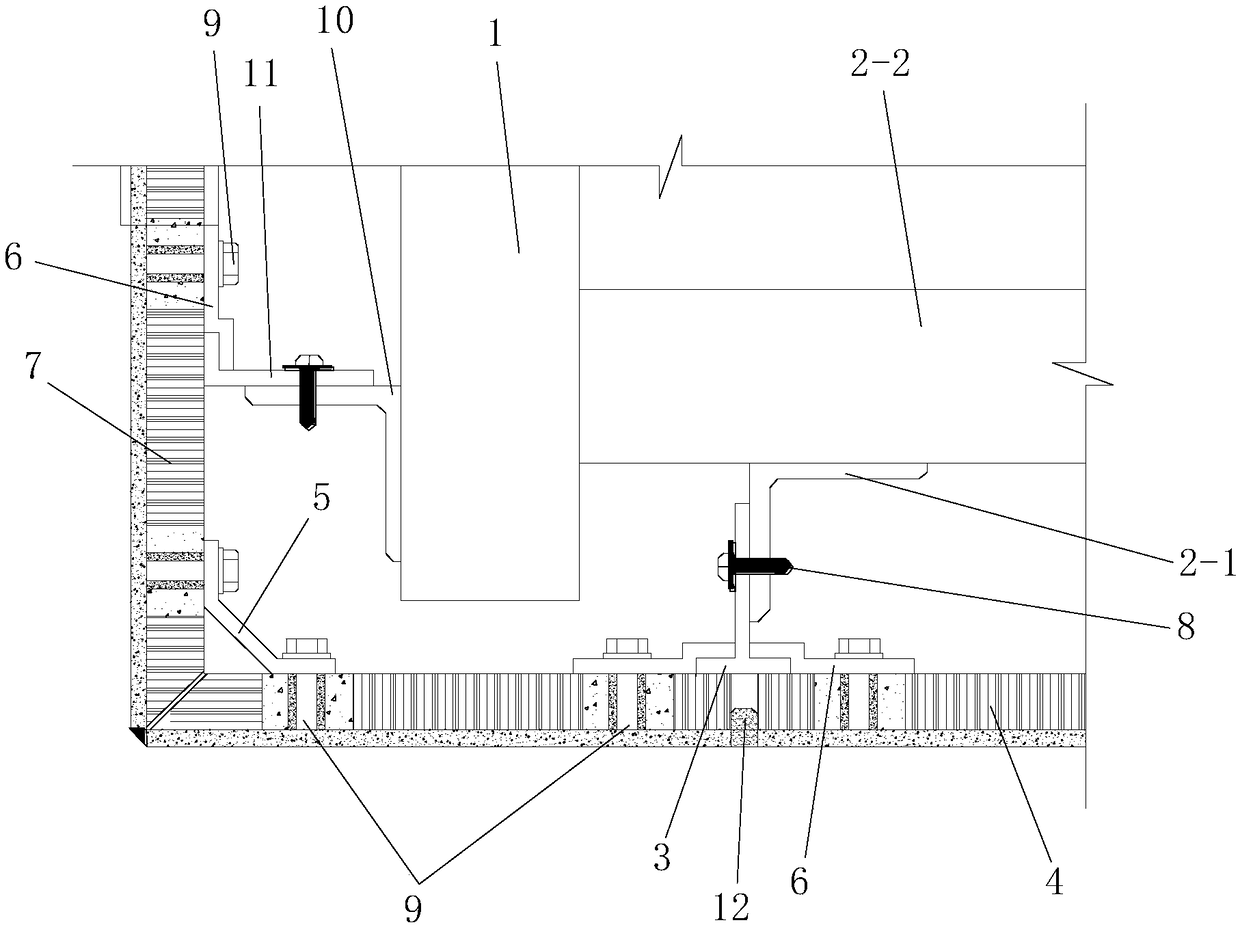

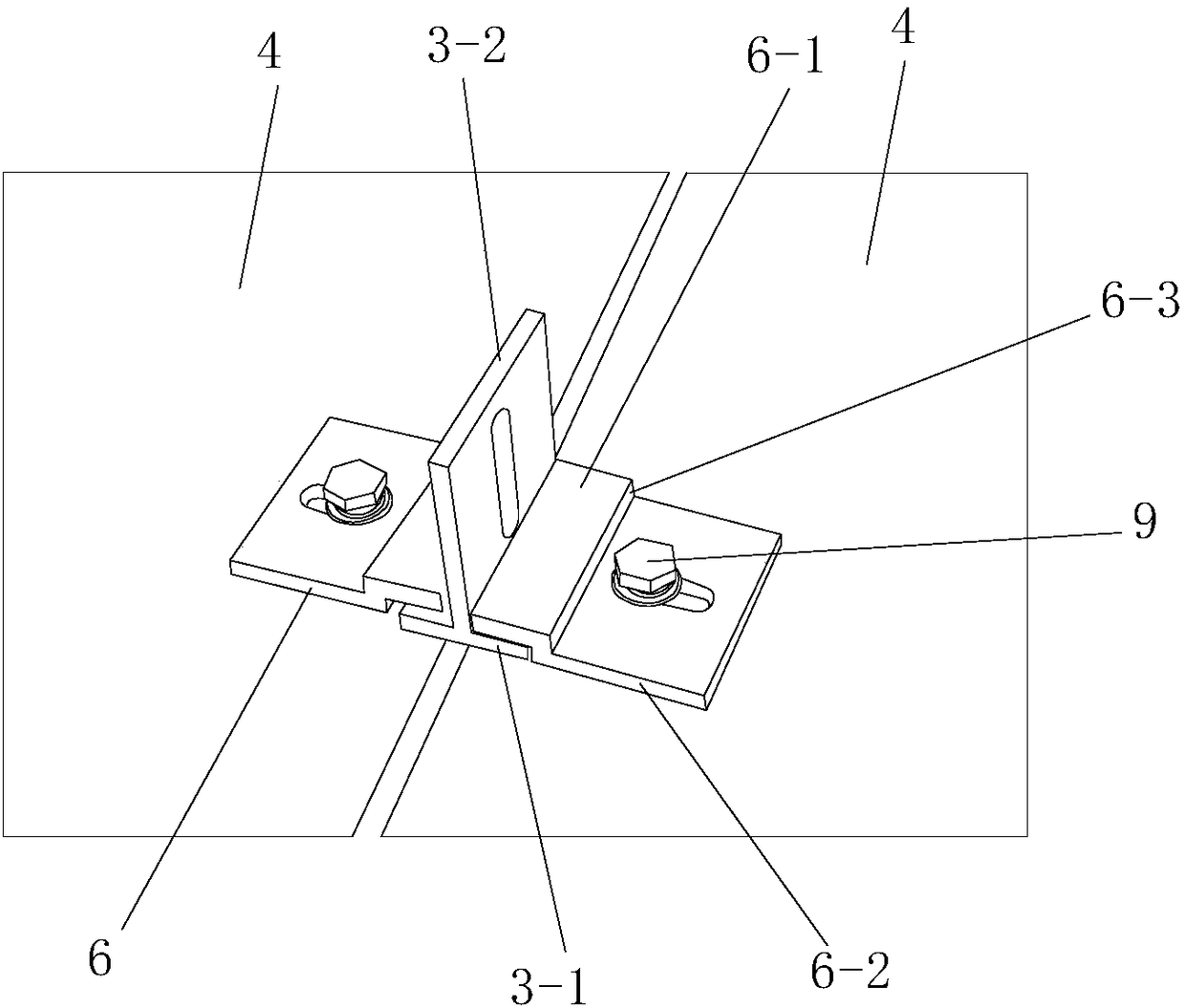

[0049] Such as figure 1 Shown is a construction method for a stone aluminum honeycomb composite panel ceiling based on T-shaped and Z-shaped pendants. The constructed stone aluminum honeycomb composite panel ceiling includes multiple rows of stone aluminum honeycomb composite panels 4 arranged in parallel and all located on the same horizontal plane. Multiple columns of the stone aluminum honeycomb composite panels 4 are arranged from left to right along the transverse width direction of the building roof, and each column of the stone aluminum honeycomb composite panels 4 includes a plurality of columns along the longitudinal direction of the building roof. The stone aluminum honeycomb composite panel 4 arranged from front to back, the stone aluminum honeycomb composite panel 4 is rectangular, see figure 2 The stone aluminum honeycomb composite panels 4 in the leftmost row and the stone aluminum honeycomb composite panels 4 in the rightmost column among the multiple columns o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com