Heating non-combustible cigarette paper and preparation method thereof

A technology for heating non-combustion and cigarette paper, which is applied in pulp beating methods, special paper, non-woody plant/crop pulp, etc., and can solve problems such as blackening of the appearance, failure to meet the actual use needs of heating-not-burn cigarettes, wrinkle deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation quantitative is 90g / m 2 Heating non-burning cigarette paper

[0026] The used fiber raw materials, inorganic fillers, reinforcing agents, sizing agents, retention aids and some process indicators are shown in Table 1 below. The particle size of inorganic fibers is required to be 0.1-4mm, and the particle size of inorganic fillers is 0.3-20 microns.

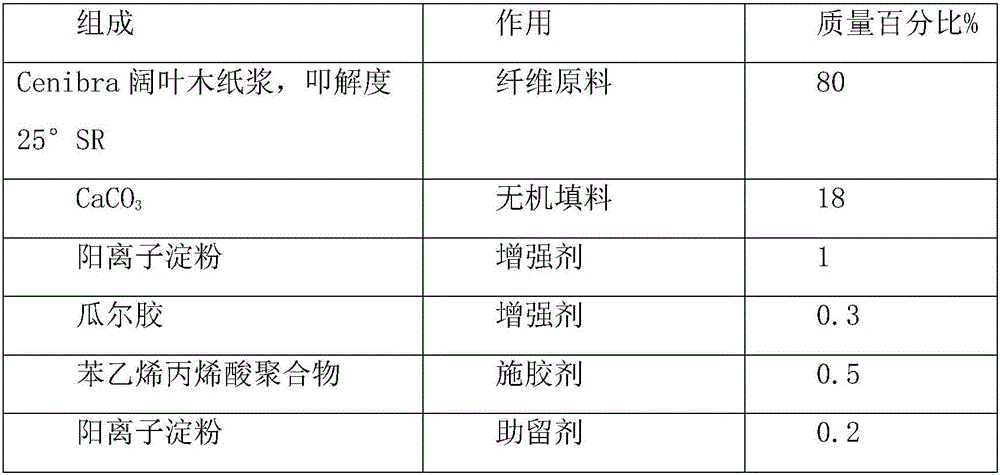

[0027] Table 1

[0028]

[0029] Other pulping and papermaking processes follow the general production process of cigarette paper.

[0030] The obtained quantitative is 90g / m 2 The heating non-combustion cigarette paper is heated and sucked with a 350℃ heating non-combustion cigarette heater. After 6 puffs, the whiteness of the cigarette paper is 80% and the whiteness retention rate is 90%. After 6 consecutive puffs, there were no tar spots or deformation problems. It shows that the heating non-combustion cigarette paper prepared by the method of the present invention can be actually used in heating non-comb...

Embodiment 2

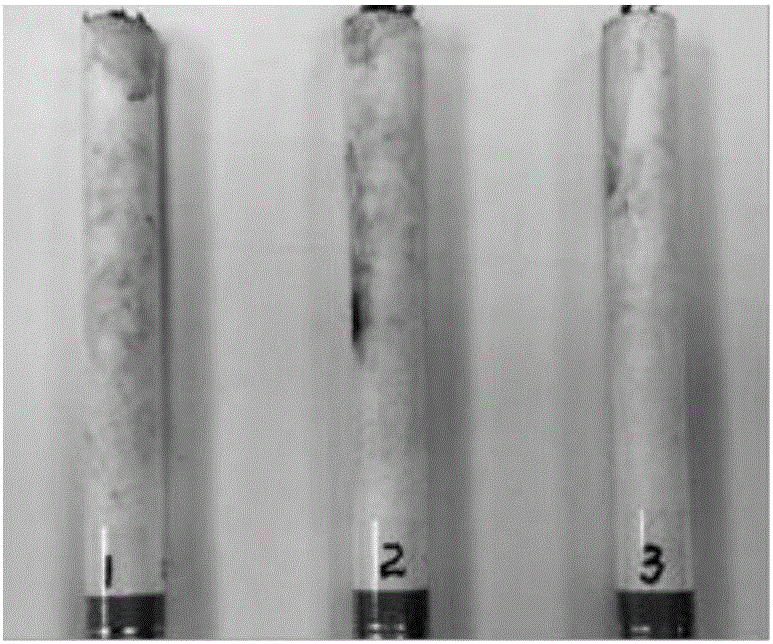

[0031] Example 2: The preparation quantity is 120g / m 2 Heating non-burning cigarette paper

[0032] The used fiber raw materials, inorganic fillers, reinforcing agents, sizing agents, retention aids and some process indicators are shown in Table 2 below. The particle size of inorganic fibers is required to be 0.1-4mm, and the particle size of inorganic fillers is 0.3-20 microns.

[0033] Table 2

[0034]

[0035] Other pulping and papermaking processes follow the general production process of cigarette paper.

[0036] The obtained quantitative is 120g / m 2 The heating non-combustion cigarette paper is heated and sucked with a 350℃ heating non-combustion cigarette heater. After 6 puffs, the whiteness of the cigarette paper is 88% and the whiteness retention rate is 98%. After 6 consecutive puffs, there were no tar spots or deformation problems. It shows that the heating non-combustion cigarette paper prepared by the method of the invention can be actually used in heating non-combustion...

Embodiment 3

[0037] Example 3: The preparation quantity is 90g / m 2 Heating non-burning cigarette paper

[0038] The used fiber raw materials, inorganic fillers, reinforcing agents, sizing agents, retention aids and some process indicators are shown in Table 3 below. The particle size of inorganic fibers is required to be 0.1-4mm, and that of inorganic fillers is 0.3-20 microns.

[0039] table 3

[0040]

[0041]

[0042] Other pulping and papermaking processes follow the general production process of cigarette paper.

[0043] The obtained quantitative is 90g / m 2 The heating non-combustion cigarette paper is heated and smoked with a 350℃ heating non-combustion cigarette heater. After 6 puffs, the whiteness of the cigarette paper is 86% and the whiteness retention rate is 96%. After 6 consecutive puffs, there were no tar spots or deformation problems. It shows that the heating non-combustion cigarette paper prepared by the method of the present invention can be successfully used in heating non-comb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com