Ship hatch negative corner packaging structure

A technology of package structure and negative angle, which is applied in the field of hatch corner structure design, can solve the problems of large liquid tank volume encroachment, accumulation of cargo, and difficulty in installing reinforcement ribs, so as to reduce the loss of liquid tank volume and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The embodiments are not intended to limit the scope of protection of the invention. Obviously, those skilled in the art can obtain other embodiments without having to pay creative work. Belong to the protection scope of the present invention.

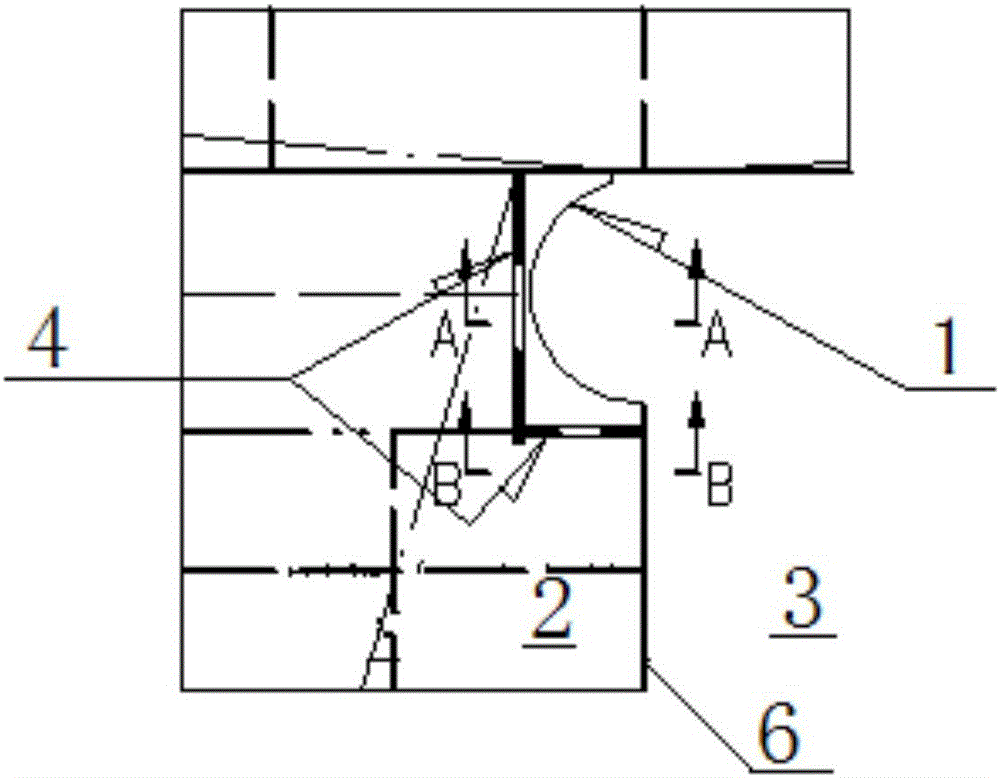

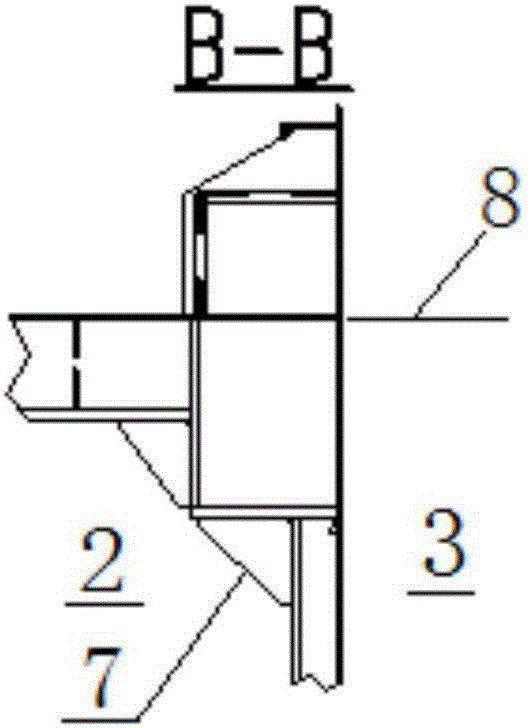

[0024] combine Figure 6 to Figure 8 As shown, a ship hatch negative corner packing structure includes a negative corner 1 fixed at the hatch, the negative corner divides the liquid tank 2 and the cargo hold 3, and the negative corner adopts a slope 5 For wrapping, the slope extends from the top of the tank to below the cargo tank. The included angle between the slope and the vertical direction is 30° to 60°.

[0025] A reinforcing rib 7 is fixed at the junction of the liquid tank 2 and the cargo tank 3, and the direction of the reinforcing rib is parallel to the slope.

[0026] The invention adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com