Double-layer rolled bumper for semitrailer

A technology for bumpers and semi-trailers, applied to bumpers and other directions, can solve the problems of increasing strength, increasing steel thickness, manual trimming, etc., and achieves the effects of increasing the impact buffering capacity, improving the safety factor, and increasing the anti-collision height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

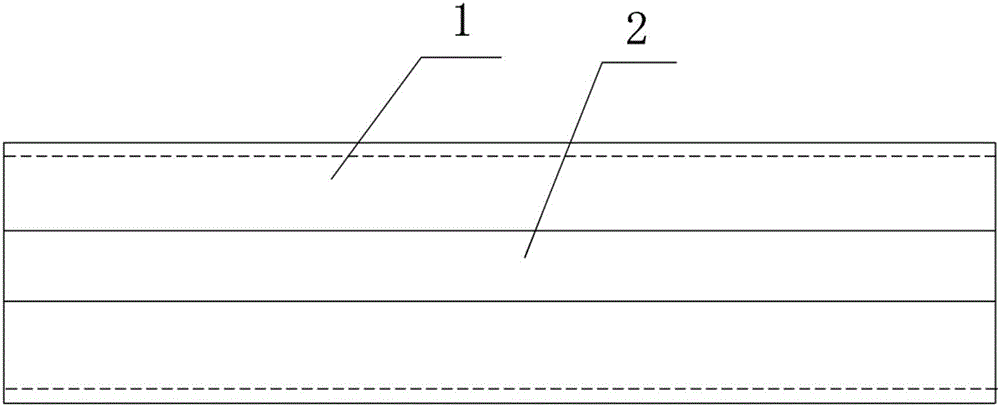

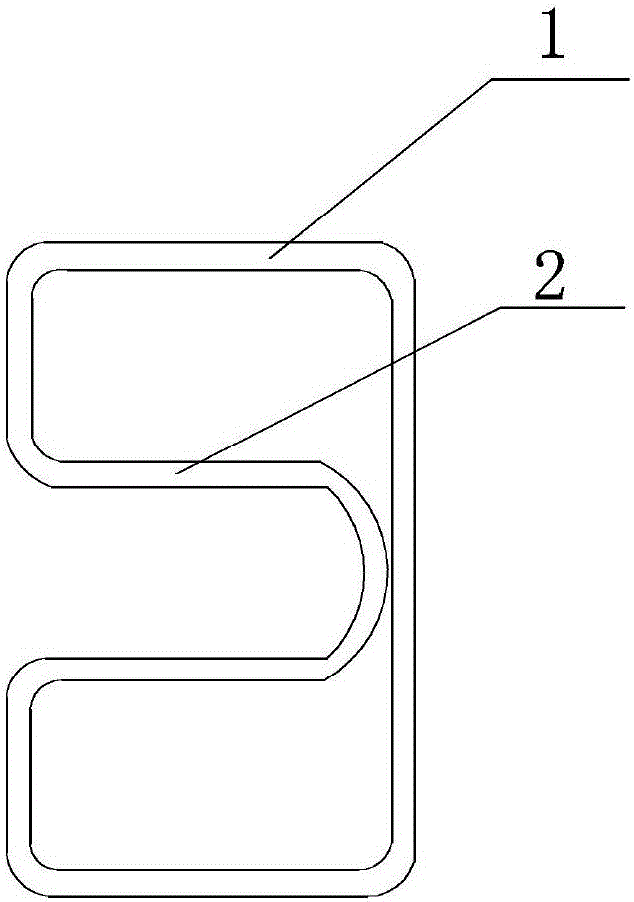

[0011] A double-layer rolled bumper for semi-trailers, comprising a lever body 1 of double-layer steel plate. The middle of the lever body 1 has a groove 2 so that the lever body 1 forms a "concave" shape, and the groove bottom of the groove 2 It is in contact with the other side of the lever body 1.

[0012] The lever body 1 is integrally formed by rolling of double-layer steel plates.

[0013] An embodiment of the present invention has been described in detail above, but the content is only a preferred embodiment of the present invention, and cannot be considered as limiting the scope of implementation of the present invention. All equal changes and improvements made in accordance with the scope of the application of the present invention should still fall within the scope of the patent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com