Full-automatic teaching blackboard

A fully automatic, blackboard technology, applied to blackboard or slate cleaning devices, reusable writing boards, printing, etc., can solve the problems of different positions, blocking of writing positions on the blackboard layout, poor writing effect, etc., and achieve fluent writing , clear writing, avoid friction and noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

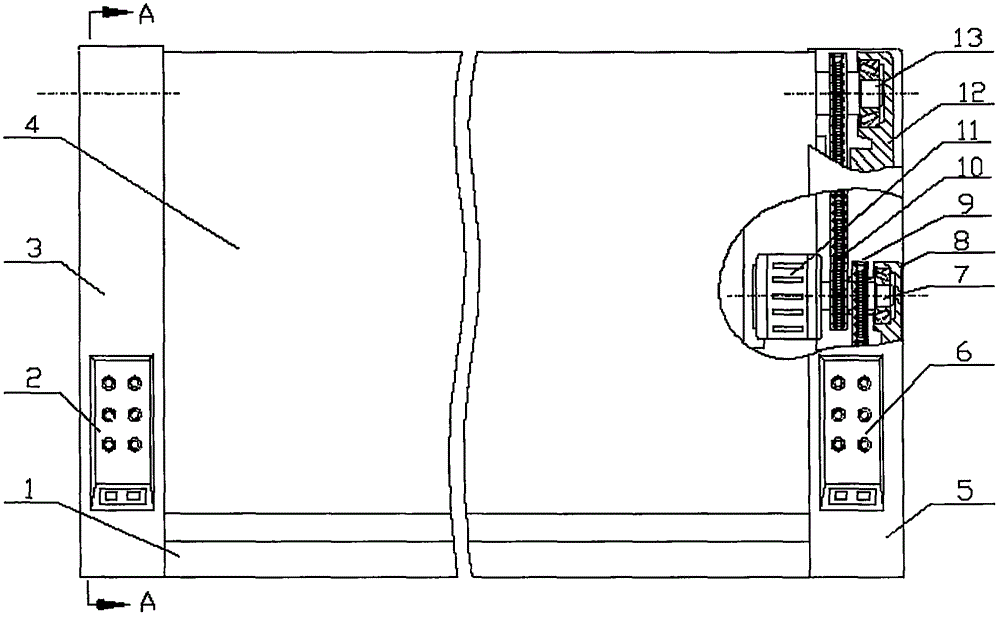

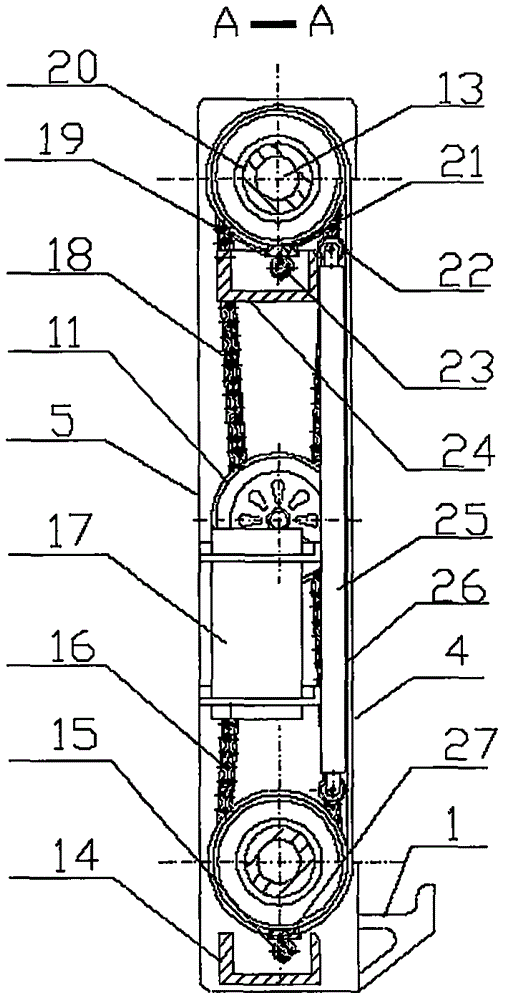

[0017] This implementation example is the specific structure of the fully automatic teaching blackboard. It is characterized in that, adopting the mechatronics method, the main motor 11 drives the chain device to drive the roll-type blackboard formed by the elastic thin steel blackboard panel 4, and uses the PLC control device to realize the setting movement of the blackboard panel 4, forming a fully automatic teaching blackboard. As shown in the figure, the structure of this example consists of: blackboard panel 4, support plate 25, upper reel 20, lower reel, main motor 11, sprocket chain device, erasing device, left control panel 2, right control panel 6, Control box 17 etc. are formed. The blackboard panel 4 is supported in the blackboard structure frame by the upper reel 20 and the lower reel. The roller sprocket (hereinafter referred to as the sprocket) and the roller chain (hereinafter referred to as the chain) driven by the main motor 11 drive the reel. drive. The ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com