Non-protein nitrogen feed additive and application thereof

A feed additive, non-protein nitrogen technology, applied in the field of animal feed, can solve the shortage of ordinary protein feed and other problems, and achieve the effects of high nitrogen content, easy purchase and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

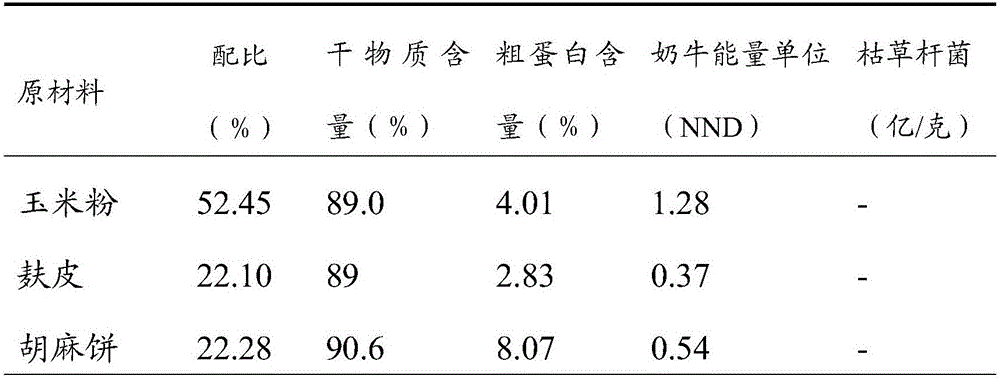

[0019] A non-protein nitrogen feed additive, consisting of the following raw material components in mass percentage: 65% corn flour, 25% urea, 8% bentonite, 1% sodium diacetate, 1% Bacillus subtilis preparation, wherein Each gram of Bacillus subtilis preparation contains 10 billion live spores. Specifically, it is prepared according to the following steps: each component is weighed according to the mass percentage of the above-mentioned raw material components, and then mixed evenly.

Embodiment 2

[0021] A non-protein nitrogen feed additive, consisting of the following raw material components in mass percentage: 60% corn flour, 30% urea, 5% bentonite, 2% sodium diacetate, 3% Bacillus subtilis preparation, wherein Each gram of Bacillus subtilis preparation contains 20 billion live spores. Specifically, it is prepared according to the following steps: each component is weighed according to the mass percentage of the above-mentioned raw material components, and then mixed evenly.

Embodiment 3

[0023] A non-protein nitrogen feed additive, consisting of the following raw material components in mass percentage: 70% corn flour, 20% urea, 7% bentonite, 2% sodium diacetate, 1% Bacillus subtilis preparation, wherein Each gram of Bacillus subtilis preparation contains 30 billion live spores. Specifically, it is prepared according to the following steps: each component is weighed according to the mass percentage of the above-mentioned raw material components, and then mixed evenly.

[0024] In order to verify the application effect of the non-protein nitrogen feed additive of the present invention, the following uses Example 1 as an experimental group to verify the effect of slow release of ammonia nitrogen and the effect on the growth of dairy cows.

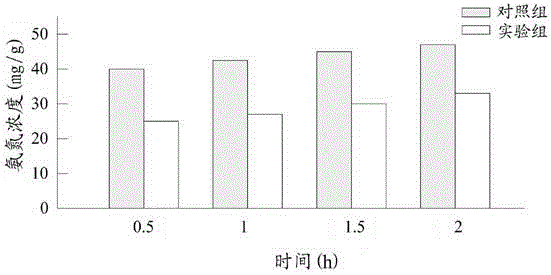

[0025] 1. Verification of slow release effect of non-protein nitrogen feed additive ammonia nitrogen

[0026] By simulating the rumen environment, the constant temperature (39° C.) water bath urease method was used to measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com