Automatic reinforcing machine

A reinforcement machine and automatic technology, applied in the electronic field, can solve the problems of different efficiency, poor manual placement accuracy, and low position accuracy, so as to improve shipment rate and quality, improve processing efficiency, and save processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

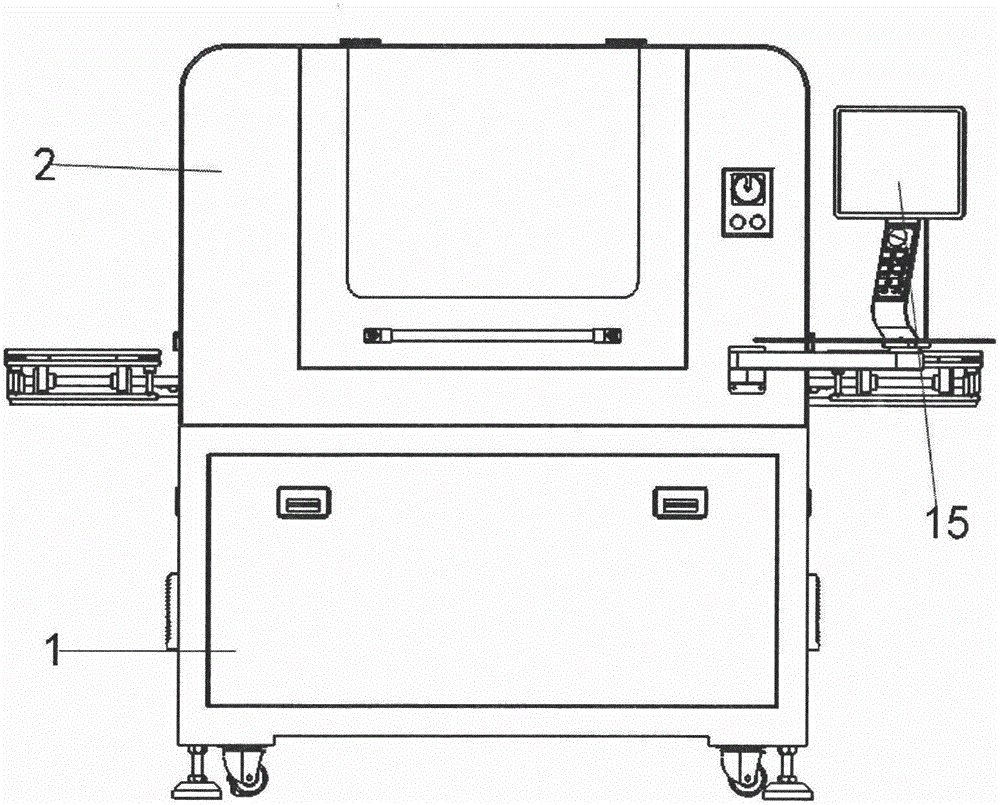

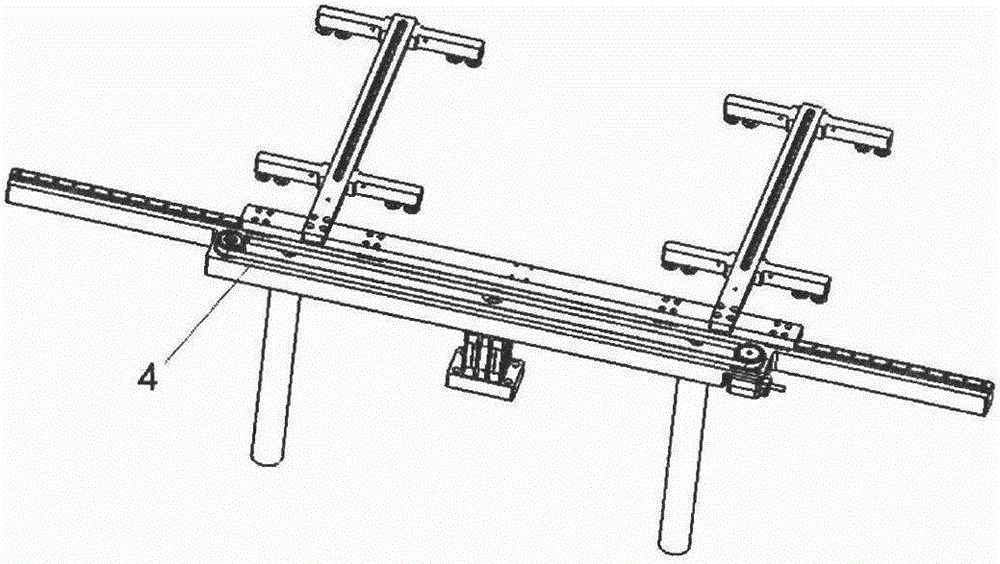

[0062] Example: such as figure 1 , figure 2 Shown, a kind of automatic reinforcing machine, it comprises machine base 1; An upper casing 2, a workbench 3, a first horizontal traverse mechanism 4, at least one adsorption mechanism, a second horizontal traverse mechanism 5 , a feed tray 7 , a third horizontal traverse mechanism 6 , a discharge tray 8 , at least one reinforcement material stripping mechanism 9 , and a reinforcement material installation mechanism 10 .

[0063] The upper casing 2 is installed on the lower base 1 as the casing of the automatic reinforcing machine.

[0064] The workbench 3 is installed on the lower machine base 1, and the workbench 3 is used to place the FPC board that needs to be attached with reinforcing materials.

[0065] like image 3 As shown, the first horizontal traversing mechanism 4 is installed on the lower base 1, and the horizontal traversing mechanism is provided with at least one installation end. The first horizontal traversing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com