Method for fusing and correcting online monitoring data and live detection data of oil-filled transformer

An oil-immersed transformer, live detection technology, applied in the field of statistical analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

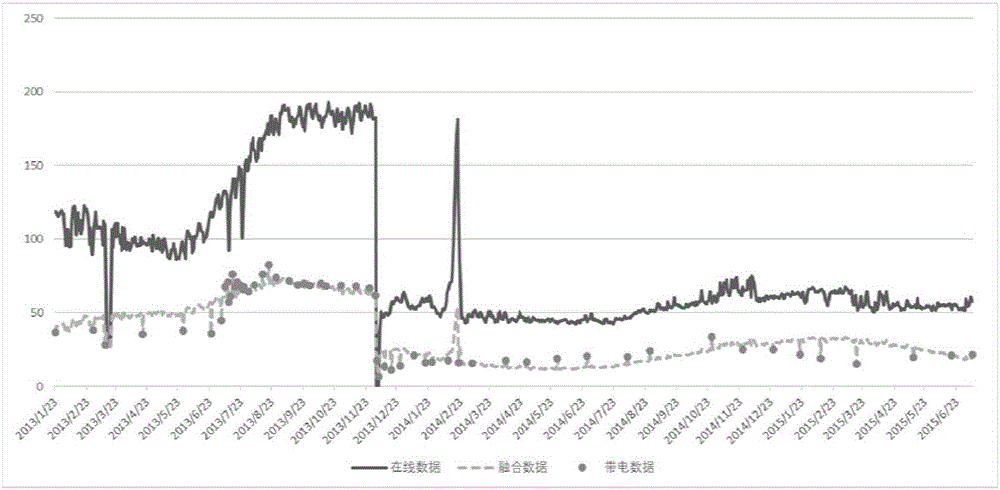

[0052] We use the following example to illustrate the effect of the fusion correction method for online monitoring data and live detection data proposed by the present invention.

[0053] First, the concentration of hydrogen in the oil of an oil-immersed transformer is obtained through remote online monitoring equipment, which is recorded as the online monitoring data; the concentration of hydrogen in the oil of the oil-immersed transformer obtained by manual sampling is recorded as the live detection data; The live detection data is preprocessed so that the time interval of the online monitoring data is the same, which is 1 day, and the time points of the online monitoring data and the live detection data correspond one-to-one. For the missing online monitoring data, the online monitoring data is filled by linear interpolation, and finally the online monitoring characteristic gas content-time series with complete observations and the charged detection characteristic gas conten...

Embodiment 2~3

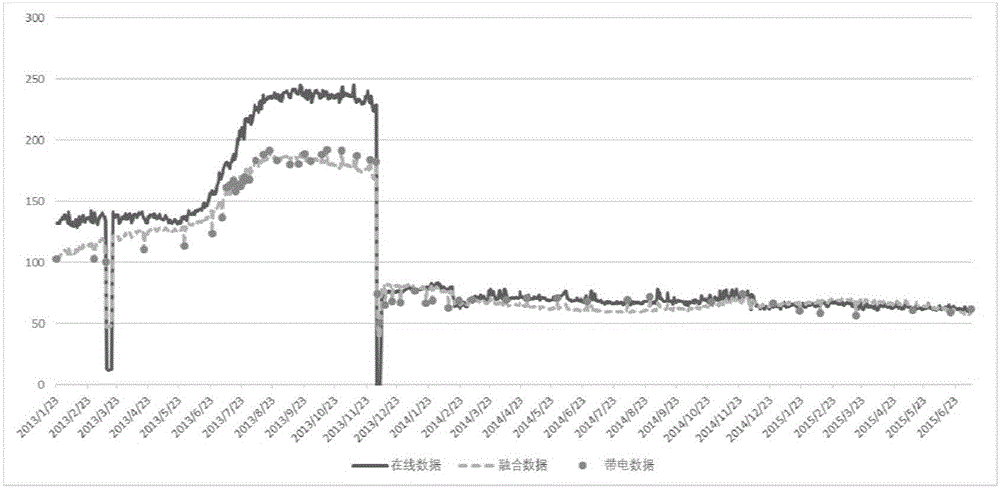

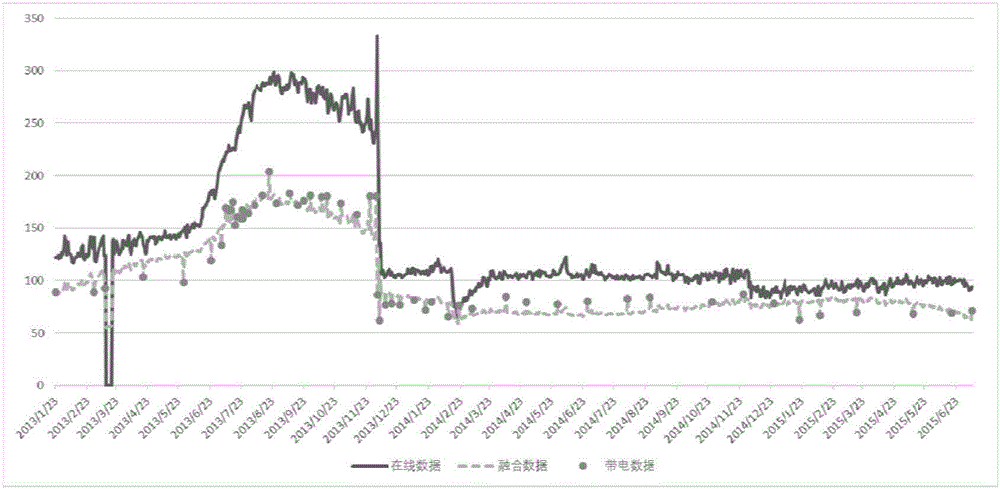

[0078] Using the same fusion correction method as in Example 1, the hydrogen concentration-time curve obtained after fusion correction, the hydrogen concentration-time curve of online monitoring and the hydrogen concentration-time curve of charged detection are shown in figure 2 , image 3 .

Embodiment 4

[0080] Using the same fusion correction method as in Example 1, the hydrogen concentration-time curve obtained after fusion correction, the hydrogen concentration-time curve of online monitoring and the hydrogen concentration-time curve of charged detection are shown in Figure 4 Top middle image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com