Strength analysis method and magnitude of interference analysis method of main bearing and shaft sleeve in wind turbine generator

An analysis method and technology for wind turbines, applied in electrical digital data processing, sustainable buildings, instruments, etc., can solve the problems that affect the accuracy of analysis and calculation, grease leakage, on the other hand, produce iron filings, polluted grease, etc., to ensure the authenticity of performance and reliability, improved accuracy, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

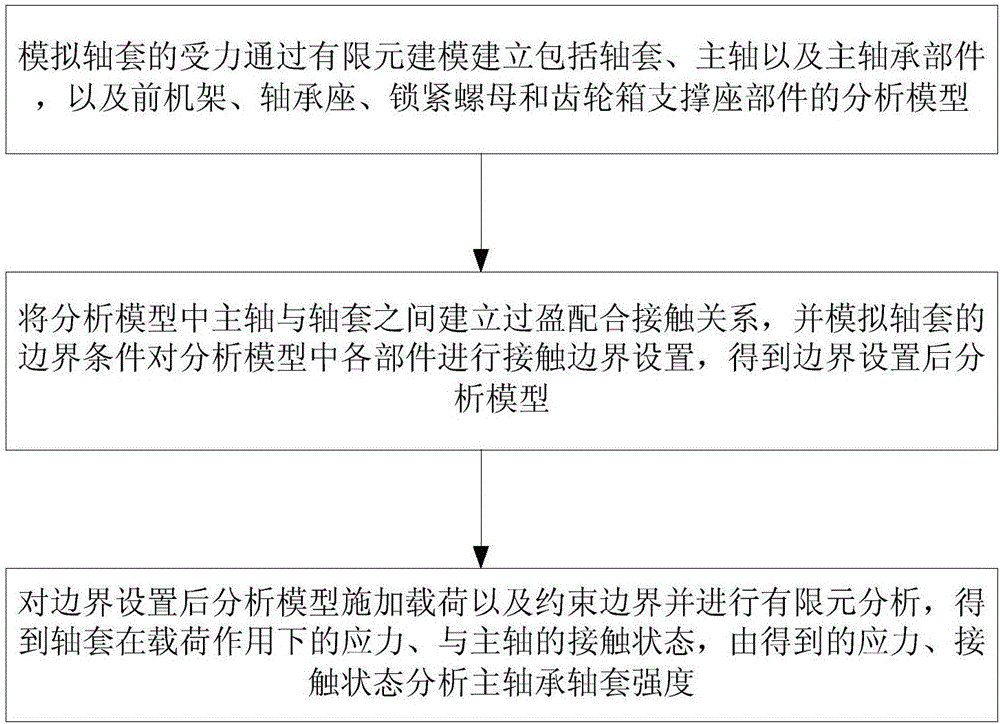

[0042] Such as figure 1 As shown, the method for analyzing the strength of the main bearing sleeve in the wind turbine in this embodiment includes:

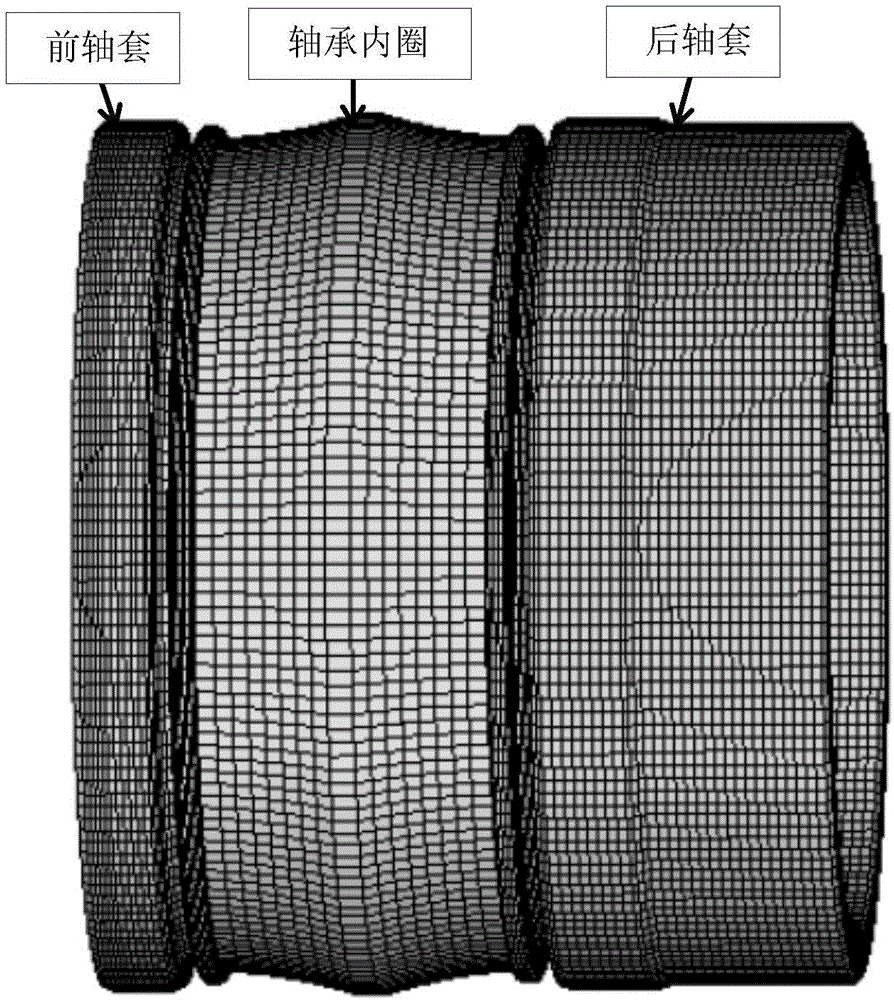

[0043] 1) Simulate the force of the bushing through finite element modeling to establish an analysis model including the bushing, main shaft and main bearing components, as well as the front frame, bearing seat, lock nut and gearbox support seat components;

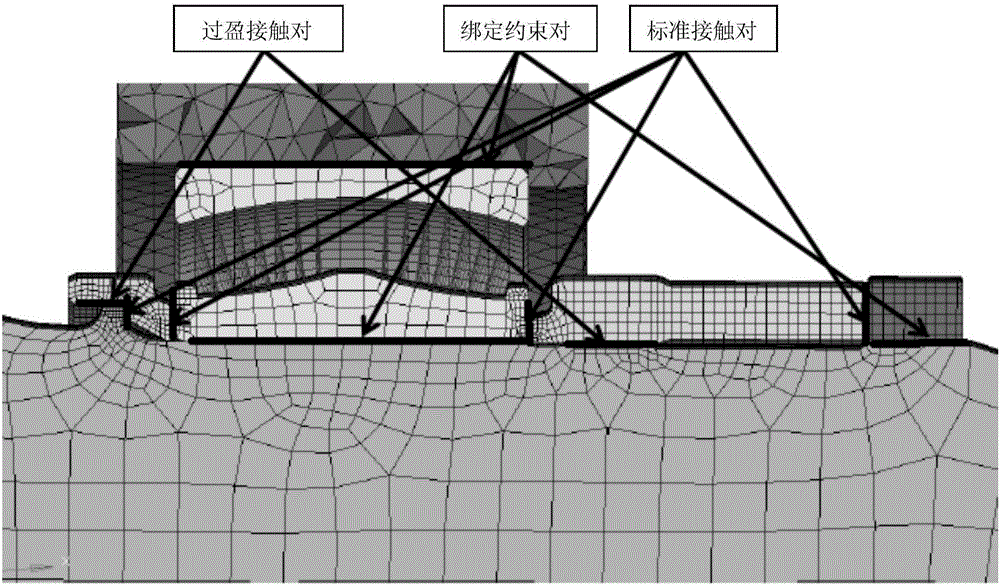

[0044] 2) Establish an interference fit contact relationship between the main shaft and the shaft sleeve in the analysis model, and simulate the boundary conditions of the shaft sleeve to set the contact boundary of each component in the analysis model, and obtain the analysis model after the boundary setting;

[0045] 3) Apply loads and constraint boundaries t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com