A connector applied to oil circuit transmission in motor vehicles

A connector and motor vehicle technology, applied in the direction of couplings, mechanical equipment, etc., can solve the problems of difficult loading and unloading, insufficient retention force of locking fasteners, and inconvenient installation, so as to improve the installation/disassembly efficiency and ensure the sealing performance. and stability, avoiding the effect of installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

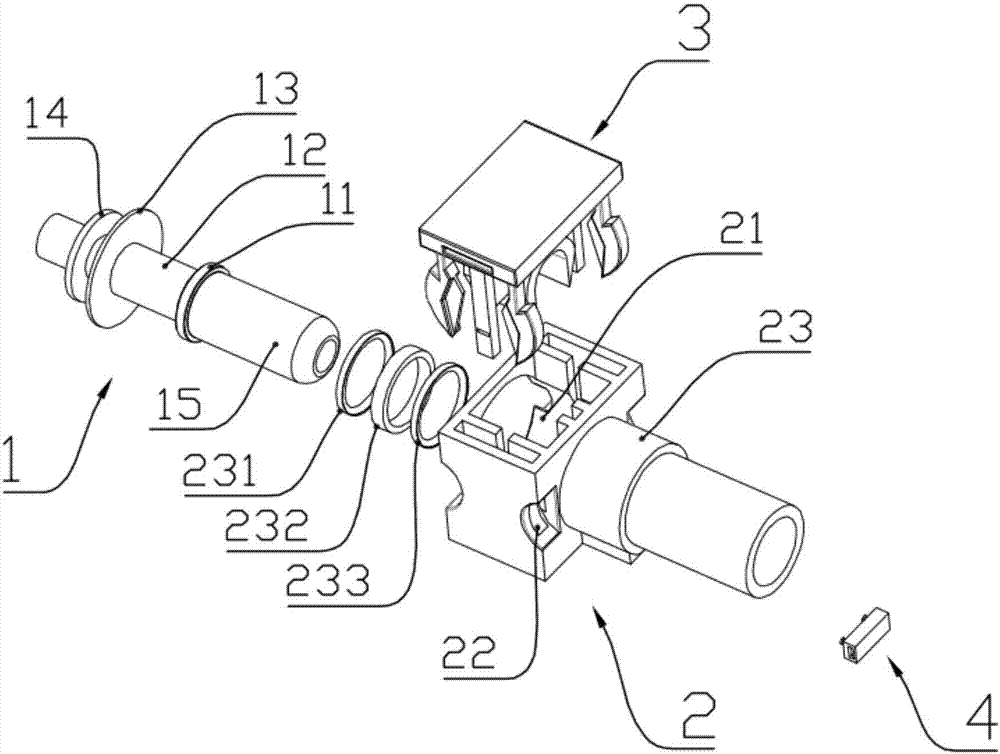

[0024] like Figure 1-8 As shown, the present invention provides a connector applied to oil circuit transmission in motor vehicles, specifically: as figure 1 and Figure 6-8 As shown, the connector includes a male connector 1 and a female connector 2, the male connector 1 is fixedly connected to the female connector 2 through a locking fastener 3; the male connector 1 is a hollow conduit, and the male connector 1 is sequentially made of The connecting pipe 15, the first annular protrusion 11, the second annular protrusion 13, the third annular protrusion 14 and the first hose connection part are integrally connected; between the first annular protrusion 11 and the second annular protrusion 13 to form a snap-fit groove 12 that can cooperate with the locking fastener 3;

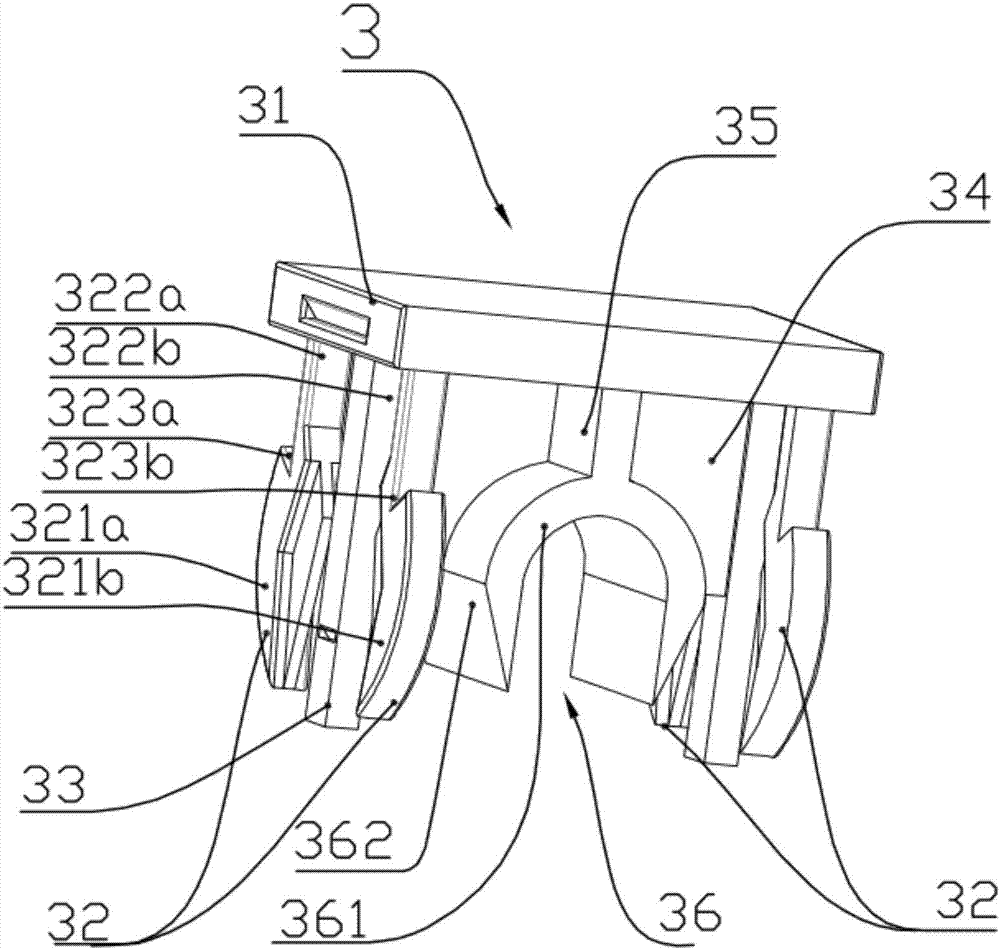

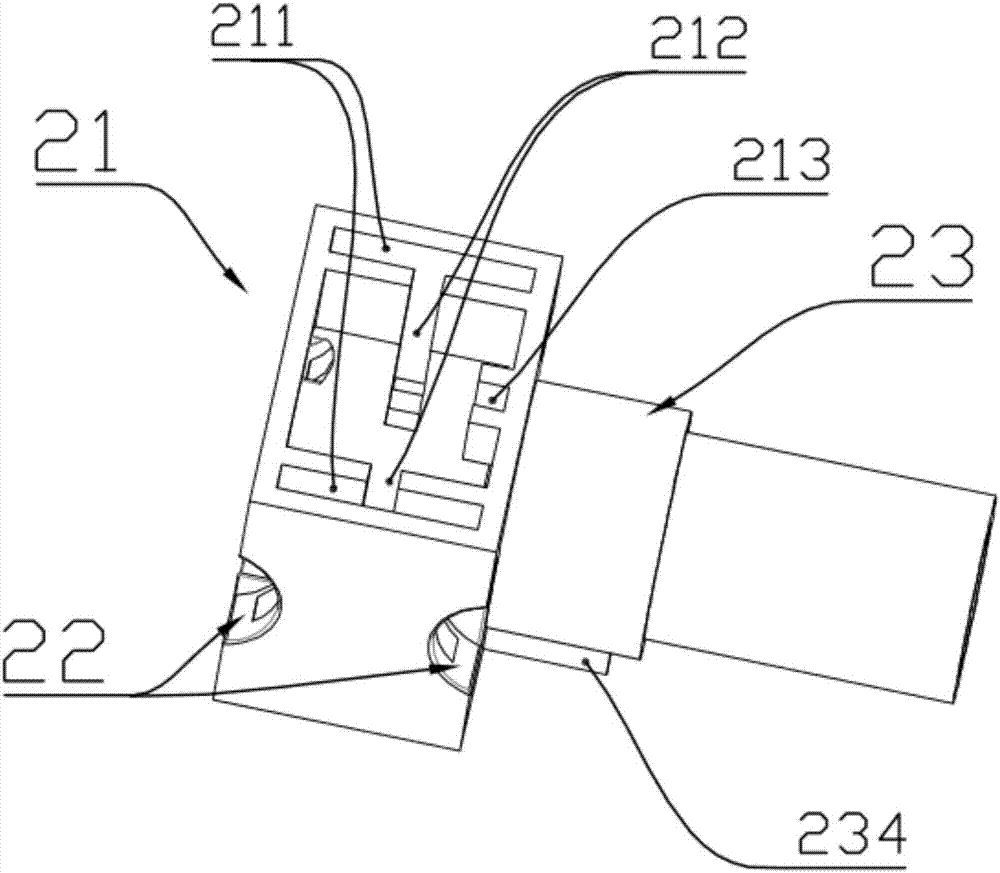

[0025] like figure 1 , image 3 and Figure 4 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com