Gear device making meshed position fully lubricated

A gear and meshing technology, used in mechanical equipment, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of lubricating oil staying on the tooth groove or tooth profile, reducing the service life of gears, and gear damage, etc. The effect of shortening the repair time, ensuring the lubrication effect and saving the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

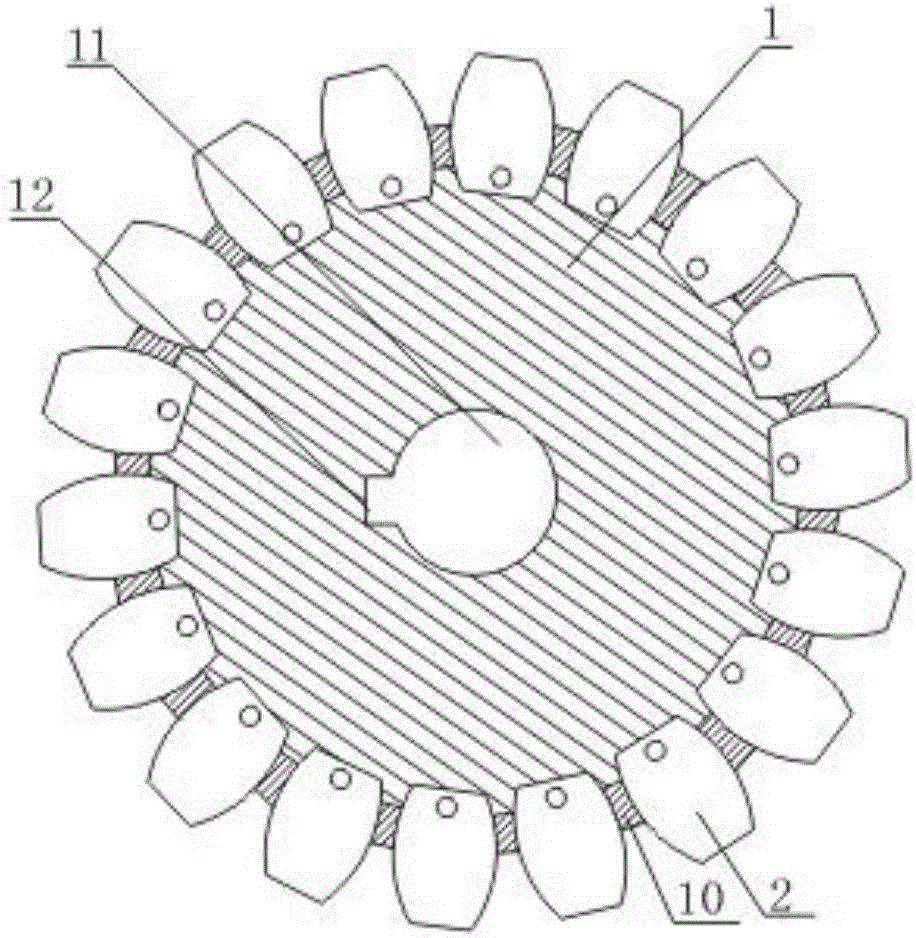

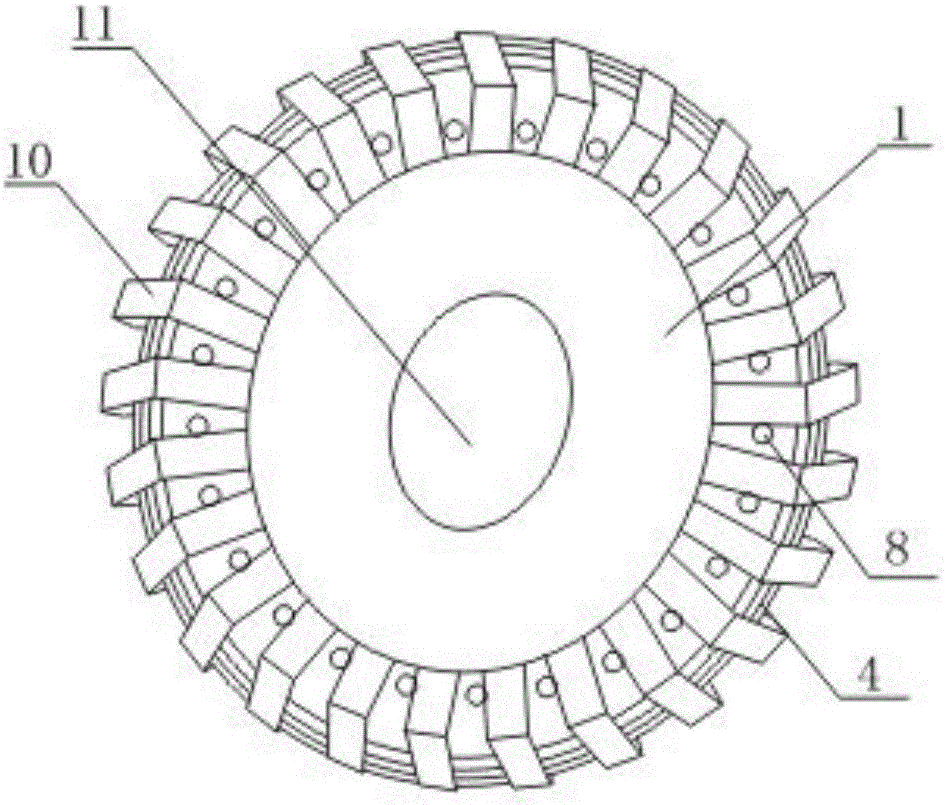

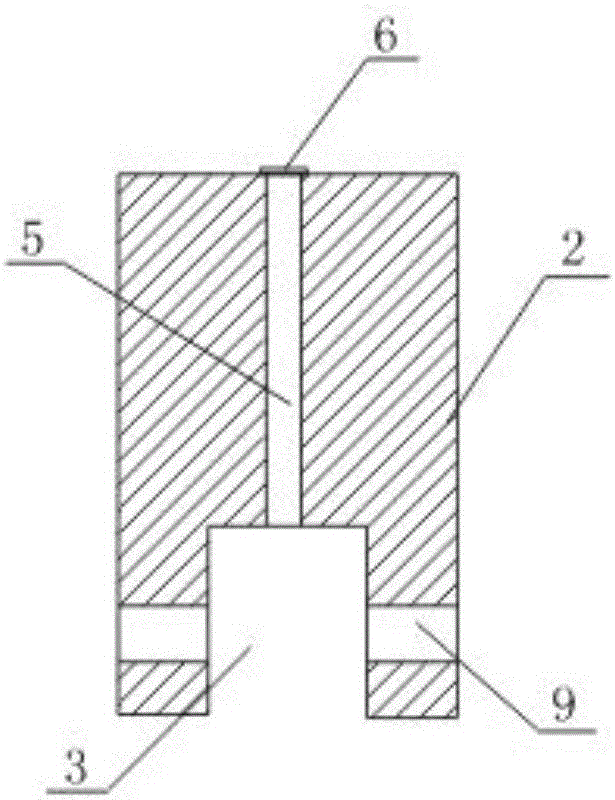

[0030] The gear equipment that is conducive to the full lubrication of the meshing parts includes a gear body 1 and a plurality of gear teeth 2 evenly distributed on the gear body 1. The lower end of the gear teeth 2 is provided with a card slot 3, and the card slot 3 at the lower end of the gear teeth 2 is detachable. The ground is clamped on the gear body 1; the outer wall of the gear body 1 is provided with a lubricating oil receiving groove 4 corresponding to the position where the gear teeth 2 are installed, and the gear teeth 2 are longitudinally provided with an oil guide channel 5 communicating with the card groove 3. The outer end surface of the tooth 2 is provided with a blocking case 6 covering the oil guide passage 5, and an oil outlet hole 7 is opened on the blocking case 6.

Embodiment 2

[0032] In this embodiment, on the basis of Embodiment 1, the gear body 1 is provided with a threaded hole A8, and the two sides of the slot 3 at the lower end of the gear teeth 2 are respectively provided with threaded holes B9 matching the threaded hole A8.

Embodiment 3

[0034] In this embodiment, on the basis of embodiment 1 or embodiment 2, several positioning protrusions 10 are evenly arranged on the gear body 1, and the gear teeth 2 are arranged between adjacent positioning protrusions 10, and the positioning protrusions 10 The height is less than the height of the gear tooth 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com