A method of recycling converter molten steel slag to produce concrete admixture

A molten, concrete technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., which can solve the problem of iron oxide recovery without considering magnesium oxide content, utilization rate of only 40%, and long treatment cycle. and other problems, to achieve the effect of maintaining a virtuous cycle, reducing the difficulty of grinding, and low basicity of converter slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

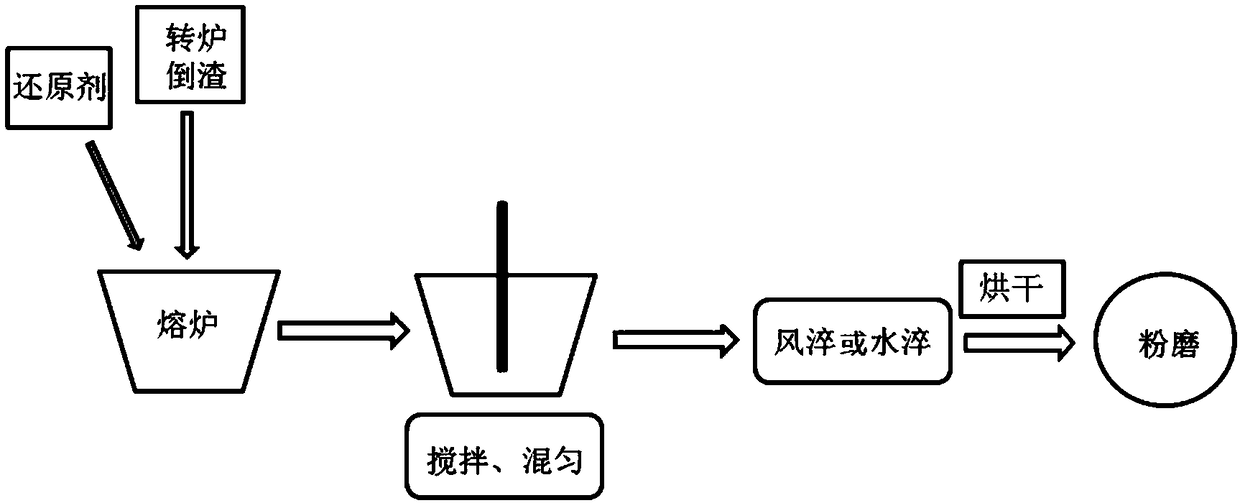

Embodiment 1

[0053] In this embodiment, a method for recovering molten steel slag from a converter to produce a concrete admixture. The raw materials for the production of the concrete admixture include 90% by mass of the molten steel slag in the early stage of the converter and 10% reducing agent. The molten steel slag in the early stage of the converter includes the following components by mass percentage: CaO, 37%, SiO 2 , 29%, FeO, 25%, MgO, 4%, Al 2 O 3 , 3%, the rest is unavoidable impurities. The reducing agent is ferrosilicon with a particle size of 5-10mm. Combine figure 1 , The steps for producing concrete admixture in this embodiment are:

[0054] (1) Pour the slag of the converter double slag retention method with a temperature of 1450°C and a slag basicity of 1.0 into the furnace, add the ferrosilicon reducing agent when the steel slag is poured into the furnace, and transport the furnace to the stirring device , Stir and mix the steel slag and the reducing agent, and then stand...

Embodiment 2

[0058] In this embodiment, a method for recovering molten steel slag from a converter to produce concrete admixtures. The raw materials for the production of concrete admixtures include 93% by mass of the molten steel slag in the early stage of the converter and 7% of the reducing agent. Steel slag includes the following components by mass percentage: CaO, 45%, SiO 2 , 25%, FeO, 20%, MgO, 5%, Al 2 O 3 , 2.5%, the rest are unavoidable impurities. The reducing agent is ferrosilicon with a particle size of 10-30mm.

[0059] Combine figure 1 , The steps for producing concrete admixture in this embodiment are:

[0060] (1) Pour the slag of the converter double slag retention method with a temperature of 1350°C and a slag basicity of 1.8 into a furnace. The furnace is an improved slag pot, the outer shell is steel plate, and the inner wall is a refractory insulation furnace lining. Add ferrosilicon reducing agent during the process of pouring steel slag into the furnace, transport the f...

Embodiment 3

[0064] In this embodiment, a method for recovering molten steel slag from a converter to produce concrete admixtures. The raw materials for producing concrete admixtures include 95% by mass of the molten steel slag in the early stage of the converter and 5% of the reducing agent. Steel slag includes the following components by mass percentage: CaO, 41%, SiO 2 , 29%, FeO, 18%, MgO, 6%, Al 2 O 3 , 3%, the rest is unavoidable impurities. The reducing agent is ferrosilicon with a particle size of 30-50mm.

[0065] Combine figure 1 , The steps of producing concrete admixture in this embodiment are:

[0066] (1) The slag of the converter double slag retention method with a temperature of 1500°C and a slag basicity of 2.0 is poured into a furnace. The furnace is an improved slag pot, the outer shell is steel plate, and the inner wall is a refractory insulation furnace lining. Add ferrosilicon reducing agent when steel slag is poured into the furnace, transport the furnace to the stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com