Sludge filtering and drying system with high efficiency and environmental friendliness

A sludge filtration and treatment system technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as secondary pollution, increased treatment costs, and complicated processes , to achieve the effect of improving the convenience of use, flexible use, and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

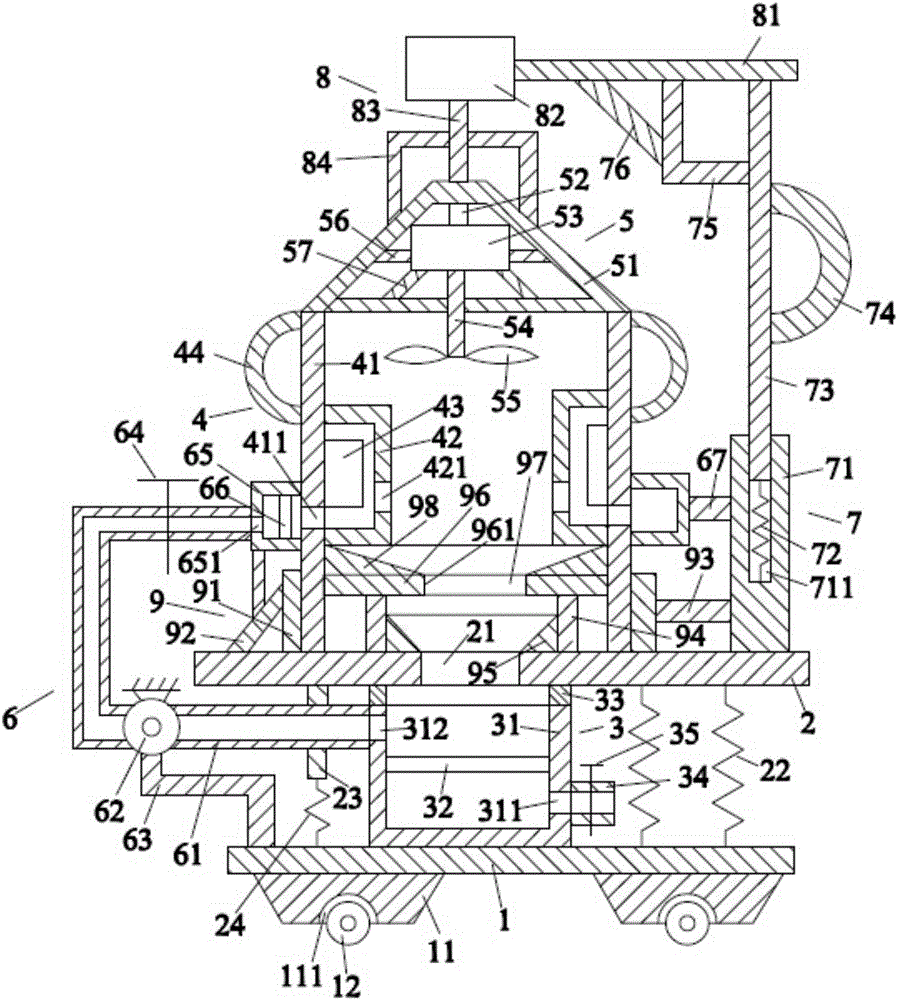

[0022] Such as figure 1 As shown, the high-efficiency and environment-friendly sludge filtration and drying treatment system proposed by the present invention includes a bottom plate 1, a support plate 2 above the bottom plate 1, and a recovery device 3 between the bottom plate 1 and the support plate 2 , the frame device 4 above the support plate 2, the fan device 5 above the frame device 4, the duct device 6 on the left side of the recovery device 3, the right side of the frame device 4 The lifting device 7 , the motor device 8 arranged on the lifting device 7 and the concentrating device 9 located above the support plate 2 .

[0023] Such as figure 1 As shown, the bottom plate 1 is rectangular parallelepiped and placed horizontally. The bottom plate 1 is provided with first support blocks 11 on the left and right sides below it and first rollers 12 arranged on the first support blocks 11 . There are two first support blocks 11, the cross section of the first support block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com