Method for treating waste water from food industry

A technology of industrial wastewater and treatment method, which is applied in the chemical industry to achieve the effects of remarkable treatment effect, large-scale treatment and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

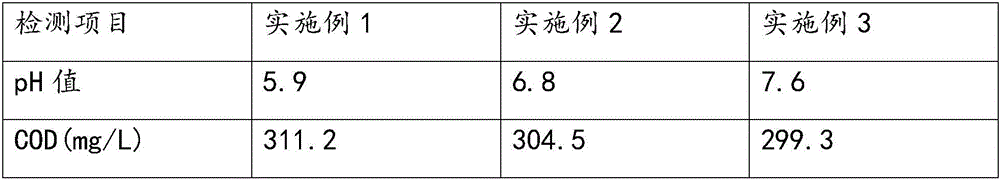

Embodiment 1

[0045] A kind of processing method of food industry waste water, it comprises the following steps:

[0046] A. Primary filtration and sedimentation

[0047] First, the waste water from the food industry flows through multiple grids with gradually reduced grid gaps, and then it is discharged into the sedimentation tank, and 10ppm of flocculant (ferrous chloride) is added for flocculation, and air is blown in for 10 minutes, and then the sedimentation treatment is carried out for 10 minutes. Promptly obtain the supernatant of industrial wastewater;

[0048] B. Ultraviolet sterilization and pH adjustment

[0049] Discharge the supernatant of industrial waste water described in step A into the acid-base adjustment tank, first sterilize with ultraviolet light, remove peculiar smell, then adjust its pH to 5.5 with alkali (sodium hydroxide), and obtain the adjusted pH value post-industrial wastewater;

[0050] C. Bacterial decomposition and activated carbon filtration

[0051]The...

Embodiment 2

[0055] A kind of processing method of food industry waste water, it comprises the following steps:

[0056] A. Primary filtration and sedimentation

[0057] First, the food industry wastewater flows through multiple grids with gradually reduced grid gaps, and then is discharged into the sedimentation tank, 35ppm flocculant (ferrous chloride) is added for flocculation, and air is blown in for 15 minutes, and then sedimentation treatment is carried out for 25 minutes. Promptly obtain the supernatant of industrial wastewater;

[0058] B. Ultraviolet sterilization and pH adjustment

[0059] Discharge the supernatant of the industrial waste water described in step A into the acid-base adjustment pool, first sterilize with ultraviolet light, remove peculiar smell, and then adjust its pH to 6.5 with alkali (sodium hydroxide), to obtain the adjusted pH value post-industrial wastewater;

[0060] C. Bacterial decomposition and activated carbon filtration

[0061] The industrial wast...

Embodiment 3

[0065] A kind of processing method of food industry waste water, it comprises the following steps:

[0066] A. Primary filtration and sedimentation

[0067] Firstly, the waste water from the food industry flows through multiple grids with gradually reduced grid gaps, and then discharged into the sedimentation tank, adding 60ppm flocculant (ferrous chloride) for flocculation, blowing in air for 20 minutes, and then performing sedimentation treatment for 40 minutes. Promptly obtain the supernatant of industrial wastewater;

[0068] B. Ultraviolet sterilization and pH adjustment

[0069] Discharge the supernatant of the industrial waste water described in step A into the acid-base adjustment pool, first sterilize it with ultraviolet rays, remove the peculiar smell, and then adjust its pH to 7.5 with alkali (sodium hydroxide), to obtain the adjusted pH value post-industrial wastewater;

[0070] C. Bacterial decomposition and activated carbon filtration

[0071] The industrial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com