Container loading and unloading system

A container and chassis technology, applied in the field of loading and unloading equipment, can solve the problems of inconvenient loading and unloading process, low loading and unloading efficiency, and narrow operating space, and achieve the effect of improving loading and unloading efficiency and reducing the number of round-trip transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

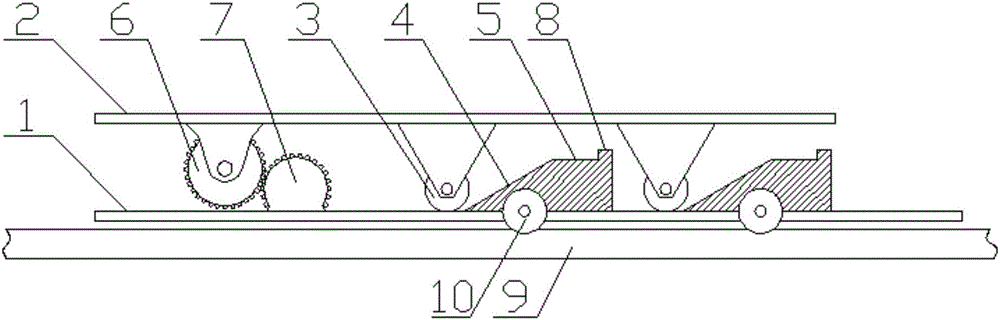

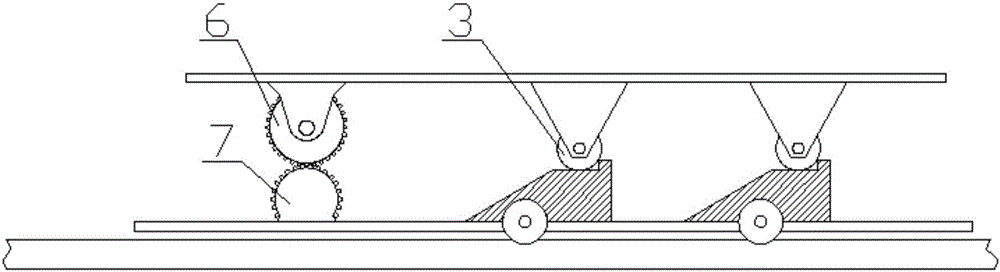

[0017] The invention relates to a container loading and unloading system, which comprises a chassis 1 with a traveling mechanism, a support plate 2 located above the chassis 1, and a lifting mechanism for adjusting the distance between the chassis 1 and the support plate 2, and the lifting mechanism includes The power traction device for displacing the support plate 2 and the chassis 1, the walking wheel 3 installed on the lower end surface of the support plate 2, and the support platform 5 fixed on the upper end surface of the chassis 1 and having a ramp 4 at one end, with the ramp 4 The supporting platform 5 is a passage for the traveling wheels 3 to ascend or descend, and the supporting platform 5 and the traveling wheels 3 are provided in one-to-one correspondence.

[0018] Specific examples, such as figure 1 and figure 2 As shown, the traveling wheels 3 are two groups arranged parallel to the front and back, and each group is two symmetrically arranged left and right, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com