Scraper conveyor and loader with fusion covering textures

A technology of scraper machine and texture structure, which is applied in the field of scraper machine and transfer machine, can solve the problems of unable to protect the easy-wear parts of the middle plate, increase energy consumption, and easy-wear failure, so as to increase the wear-resistant support area and reduce The direct contact area and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

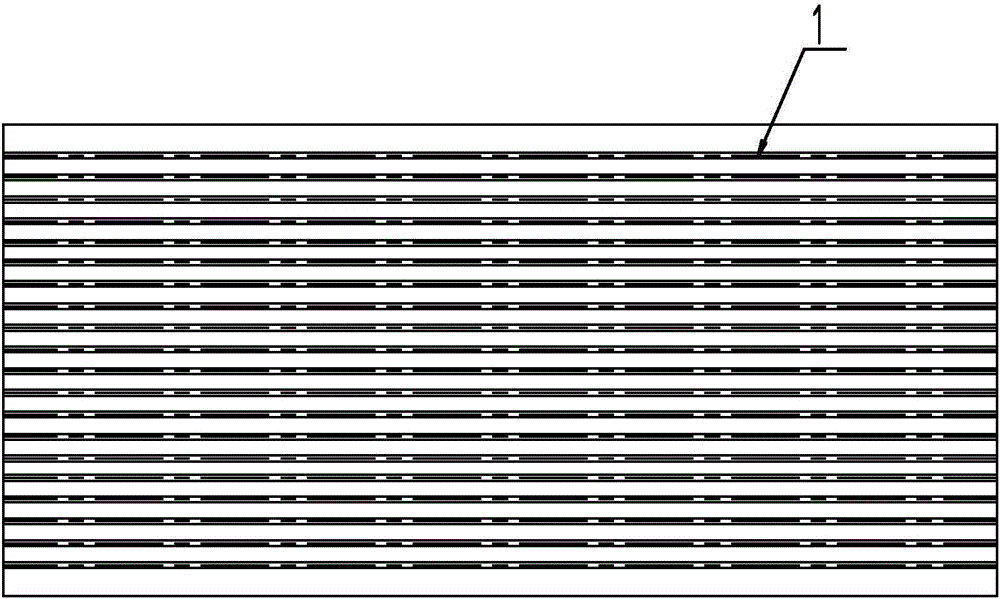

[0047] Such as figure 1 As shown, a scraper machine with a cladding texture includes a middle plate, a bottom plate and a channel side steel. The middle plate is clad with a straight line uniform texture higher than the middle plate, and the straight line uniform The texture is composed of straight wear-resistant strips 1, the height of the straight wear-resistant strips 1 is 1.5mm, the width is 9mm, and the distance between the centerlines of adjacent straight wear-resistant strips 1 is 10-50mm. The straight line uniform texture structure of this embodiment is simple, there is no overlapping point at all, and the running resistance of coal flow is reduced. The contact and wear with the medium plate substrate does not require full cladding, which reduces the cost.

Embodiment 2

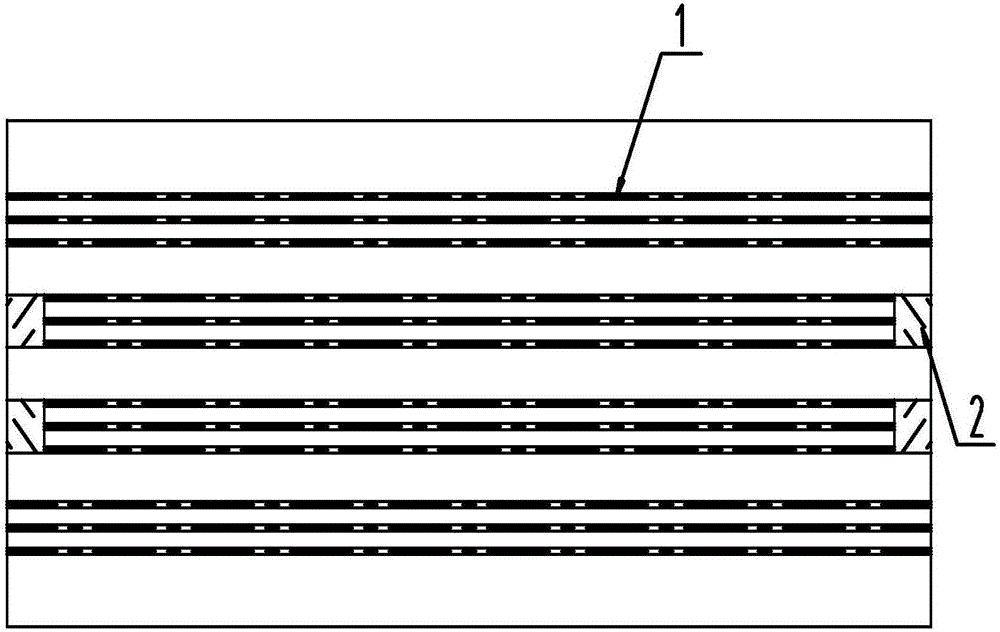

[0049] Such as figure 2 As shown, a scraper machine with a cladding texture includes a middle plate, a bottom plate and a channel side steel, and the middle plate is clad with a linear distribution texture and a wear-resistant block 2 higher than the middle plate, so The linear distribution texture is composed of linear wear strips 1. The height of the linear wear strips 1 is 1.6mm and the width is 8mm. The distance between the centerlines of the straight wear-resistant strips 1 is 18mm, and the maximum distance between the straight-line wear-resistant strips 1 between adjacent groups is 60mm. When the scraper machine is working, the two raised parts on the lower surface of the scraper continuously rub against the middle plate, forming failure marks on the surface of the middle plate, which eventually causes the middle plate to fail. The position of the two sets of linear wear-resistant strips 1 on the outside of this embodiment is opposite to the raised part of the scraper,...

Embodiment 3

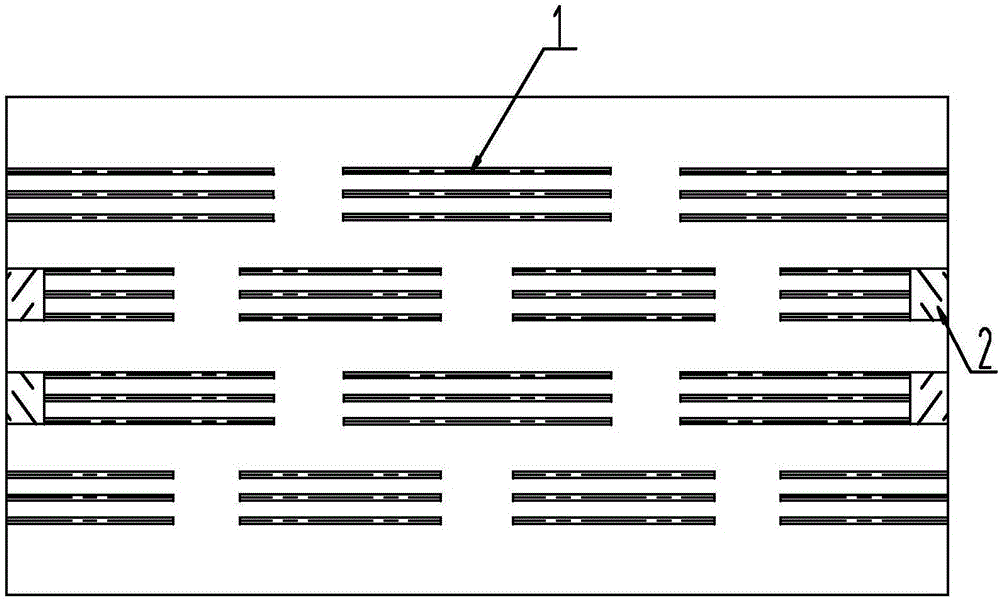

[0051] Such as image 3 As shown, a scraper machine with a cladding texture, the same part as the second embodiment will not be repeated, the difference is: this embodiment is a linear intermittent texture, the linear wear-resistant strip 1 is intermittent, the same The discontinuous positions of the linear wear strips 1 of the groups are the same, and the discontinuous positions of the linear wear strips of adjacent groups are different. In addition to the effect of the second embodiment, the linear intermittent texture of this embodiment also has the effect of reducing the deformation of the middle plate after cladding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com