Pantograph

A pantograph and bow head technology, applied in the field of pantographs, can solve the problems of large wind resistance, large force of spring boxes and other components, and short fatigue life, so as to reduce air lift force, improve flow stability, and improve The effect of fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

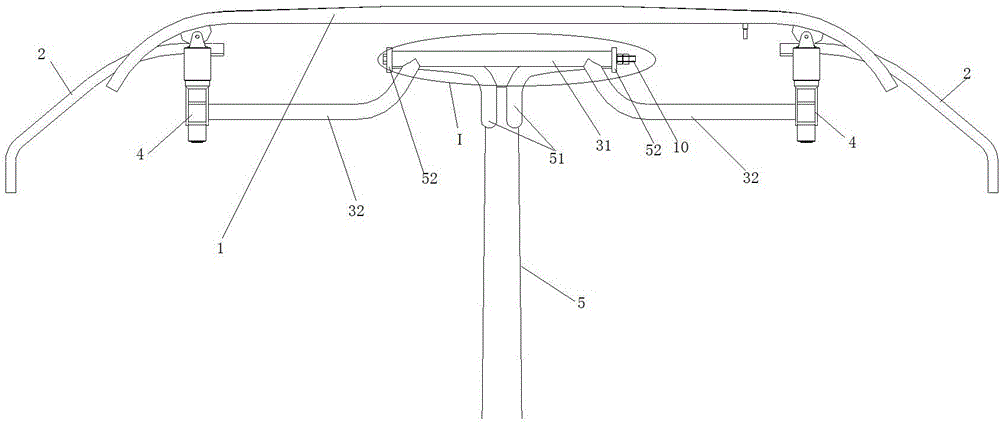

[0049] Such as Figure 1-8 As shown, a pantograph includes a chassis 6, a lower arm 7 mounted on the chassis 6, an upper arm 5 hinged to the lower arm 7, one end hinged to the lower end of the upper arm 5 and the other end to the chassis 6Hinged pull rod 9, lifting bow driving device, and bow head 17, said bow head 17 includes bow angle 2, bow head rotating shaft 3, elastic buffer devices connected to both ends of bow head rotating shaft 3, two ends across bow head rotating shaft 3 The elastic buffer device at the end and the slide plate 1 fixedly connected with the elastic buffer device. The elastic buffer device is preferably a spring box 4 . The spring box 4 is provided with a bow horn mounting plate, and the bow horn 2 is mounted on the bow horn mounting plate. The upper end of the upper arm 5 is extended with a connecting portion 12 , and the connecting portion 12 is hinged to the bow head rotating shaft 3 .

[0050] The distance between the connecting position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com