Automotive three-clutch hybrid power transmission system

A three-clutch, hybrid technology, applied in the arrangement of multiple different prime movers, power units, pneumatic power units, etc. It does not have problems such as hybrid and other working modes, and achieves the effects of convenient shifting process, high energy use efficiency, and clear hybrid transmission route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

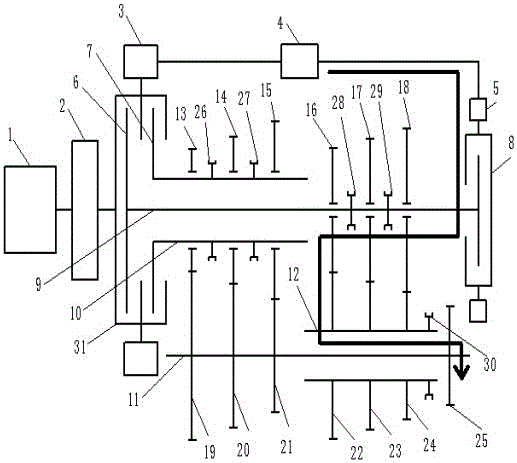

[0017] A three-clutch hybrid power transmission system for vehicles, consisting of an engine (1), a dual-mass flywheel (2), a generator (3), an energy storage device (4), an electric motor (5), and three clutches (6, 7, 8) , two input shafts (9, 10), two output shafts (11, 12), six idle gears (13, 14, 15, 16, 17, 18), seven fixed gears (19, 20, 21 , 22, 23, 24), five synchronizers (26, 27, 28, 29, 30).

[0018] All idler gears described in the present invention can rotate relatively with the shafts supporting them, but cannot move relatively; all synchronizers can move relatively with the shafts supporting them, but cannot rotate relatively; A whole, which cannot produce relative motion with the axis.

[0019] All synchronizers described in the present invention have three positions, namely the left position, the middle position and the right position. When the synchronizer is in the left position, it combines with the idle gear on its left to make the idle gear on its left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com