A flaring device for pvc pipe

A PVC pipe and heating device technology, applied in the field of PVC pipe processing, can solve the problems of inability to control the heating temperature and length of the PVC pipe, low degree of automation of the expansion of the PVC pipe, and achieve the effects of avoiding errors, saving energy, and uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

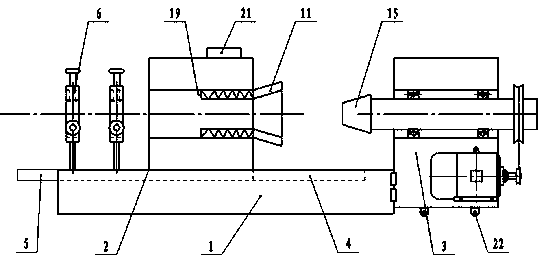

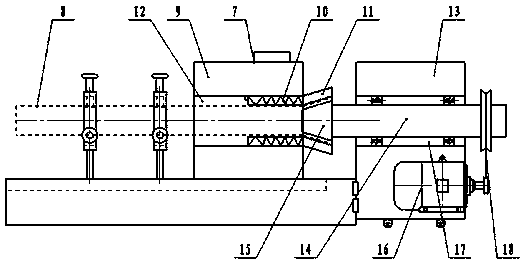

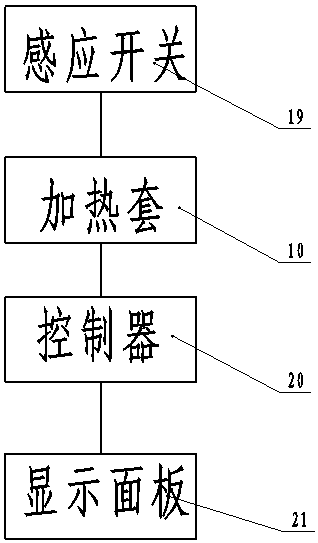

[0025] Such as Figure 1-2 As shown, the present invention is used for a PVC pipe flaring device, including a fixed table 1, a PVC pipe heating and flaring device 2 arranged on the fixed table 1, and a PVC pipe flaring mold device 3 arranged at the front end of the fixed table 1 , because the inner diameter of the heating jacket 10 cannot be separated from the outer diameter of the PVC pipe 8 too far, and the flaring of the PVC pipe 8 cannot be taken out from the rear end, by designing the heating part of the PVC pipe mouth and the part of the flaring mold into a separate structure, it is convenient for the expansion of the PVC pipe Take it out after the mouth, which improves the flaring efficiency; the fixed table 1 is provided with a dovetail chute 4; the PVC pipe heating and flaring device 2 includes a dovetail moving block 5, a moving clamping frame 6, a PVC pipe heating device 7, and a dovetail moving block 5 The dovetail chute 4 set on the fixed table 1 slides inside, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com