A wire type kiwi fruit cutting device

A technology of kiwi fruit and steel wire, which is applied in metal processing and other directions, can solve the problems of concentrated extrusion force on the contact pressure surface, difficulty in ensuring thickness consistency, time-consuming and labor-intensive problems, etc., to achieve reduced deformation probability, small resistance, flexible and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

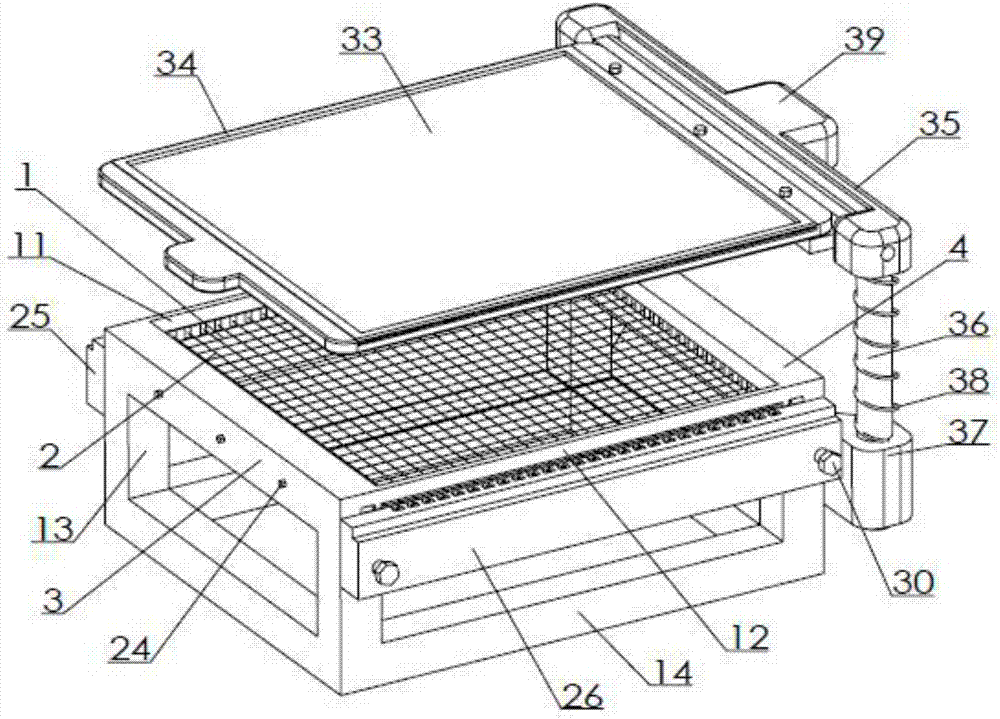

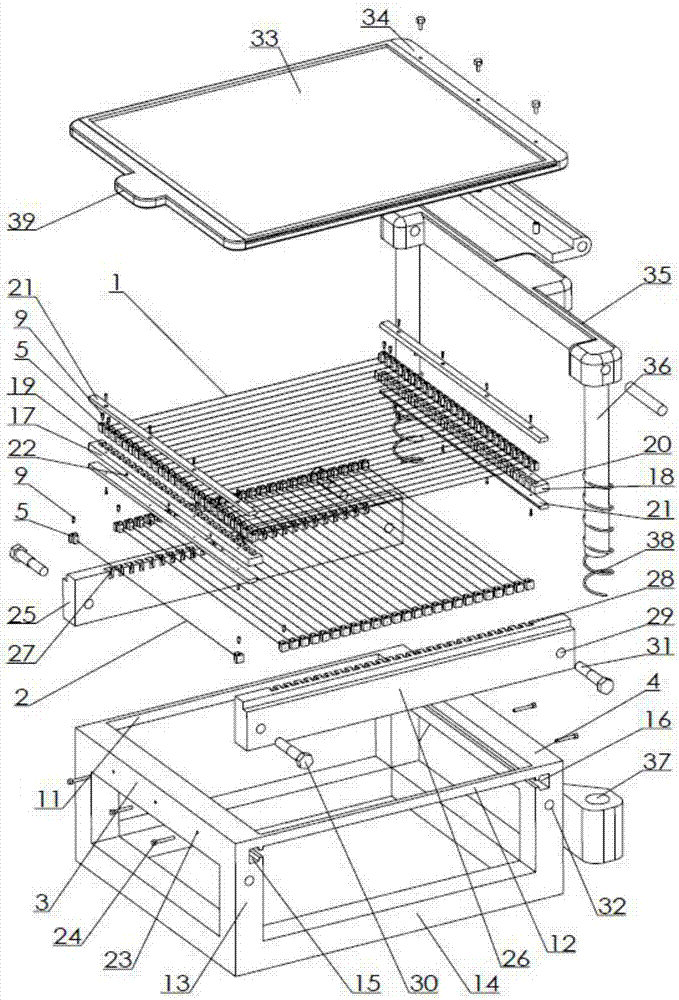

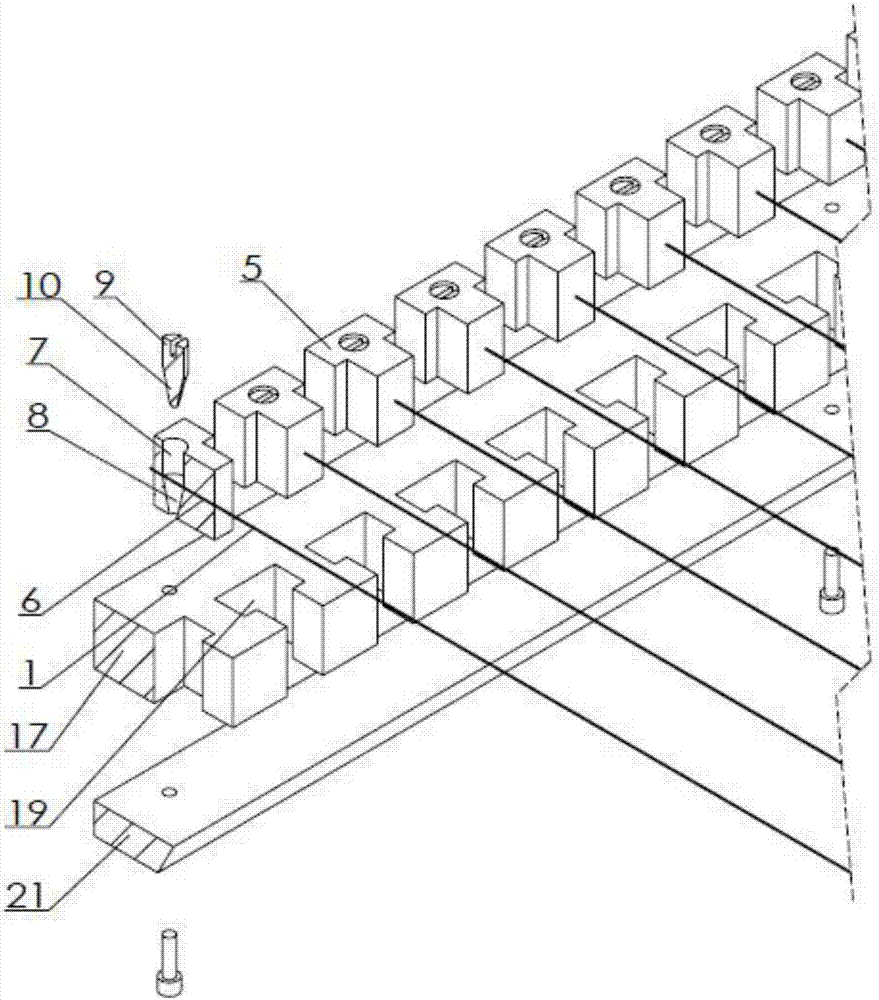

[0015] Examples of the present invention figure 1 , 2 , shown in 3, this steel wire type kiwi fruit cutting device is provided with upper strata steel wire 1, lower strata steel wire 2 and parallel and is in same horizontal height left crossbeam 3 and right crossbeam 4, the diameter of upper strata steel wire is 0.1mm to 0.3mm, the diameter of bottom strata steel wire The diameter is 0.3mm to 0.5mm, and the lower layer is thicker than the upper layer of steel wire. When they are close together, they can provide better bearing strength for the upper layer while maintaining sharpness. Both ends of the upper layer of steel wire and the lower layer of steel wire are connected with a connecting block 5, and the side of the connecting block There is a horizontal wire hole 6 in the middle for the end of the wire to pass through, a threaded hole 7 down to the wire hole is provided on the connecting block, a tapered hole 8 is provided at the bottom of the threaded hole, and a fastening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com