A high-voltage transformer bottom plate grounding device

A high-voltage transformer and grounding device technology, applied in the direction of connecting contact materials, etc., can solve the problems affecting the verification efficiency of transformers, slow manual wiring speed, uncertain grounding position, etc., to improve verification efficiency, fast grounding speed, and easy to use. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

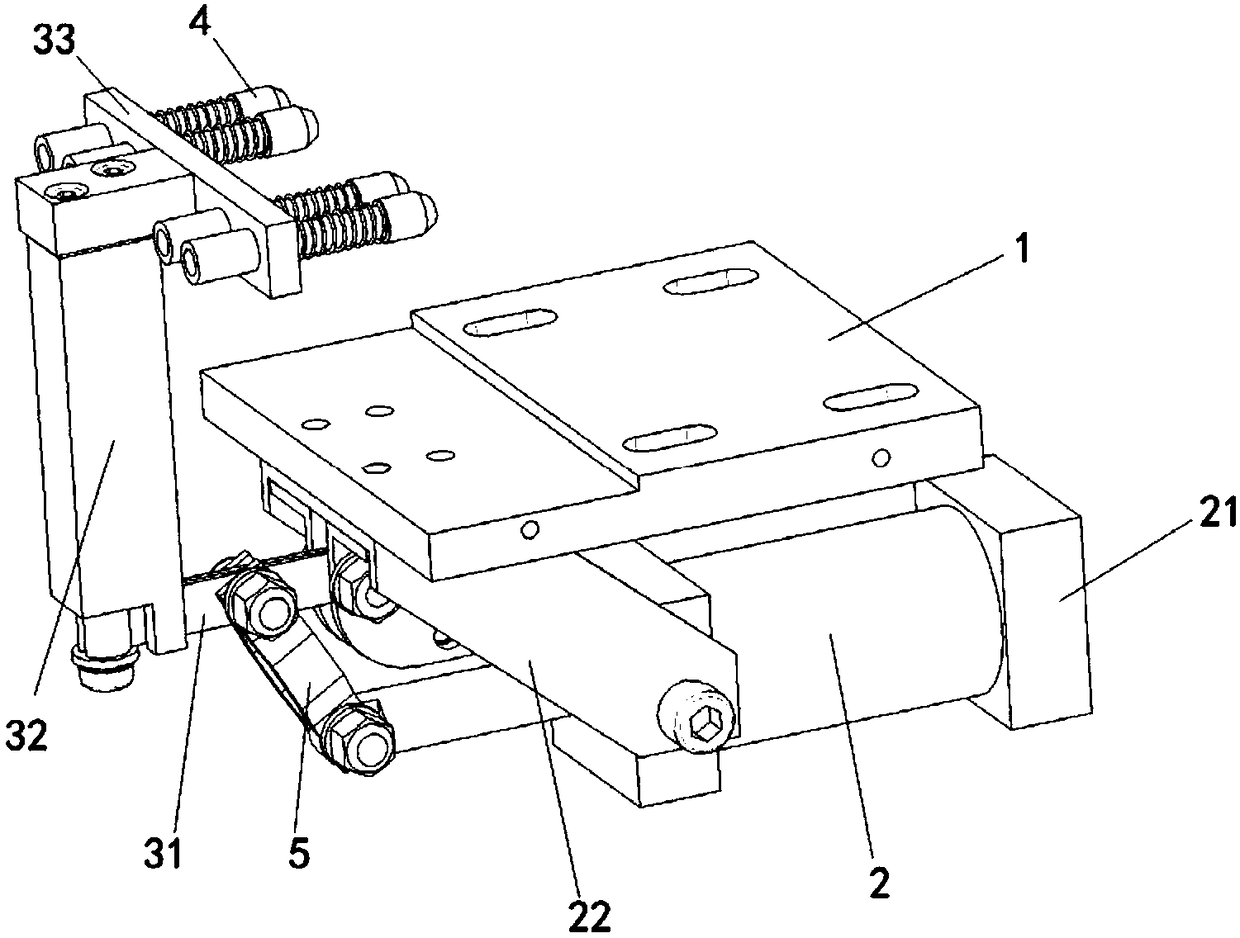

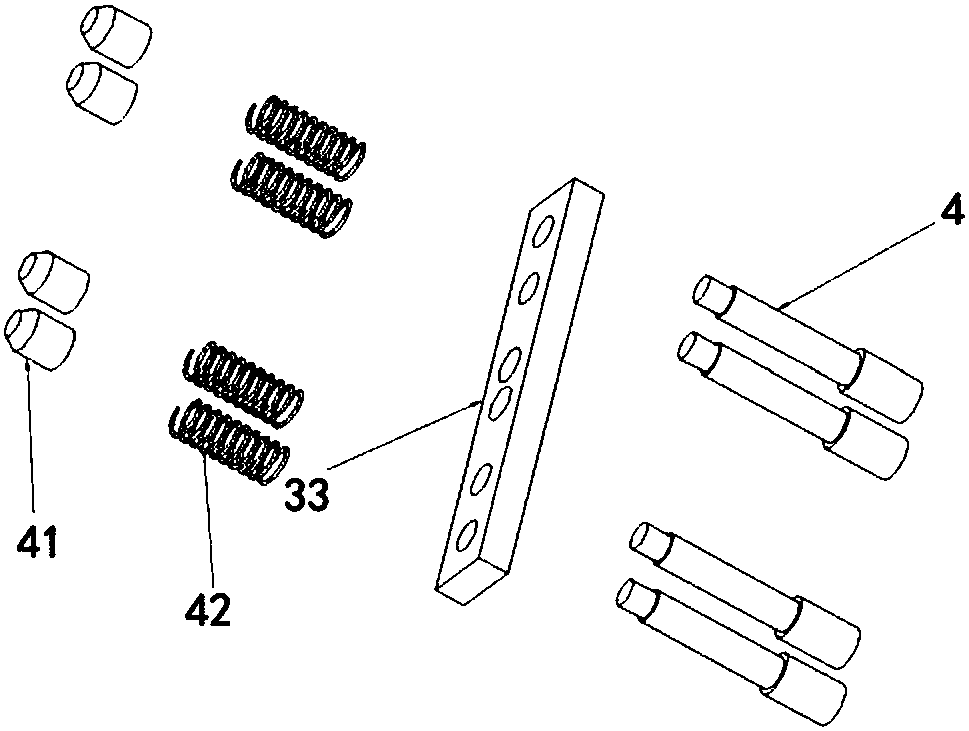

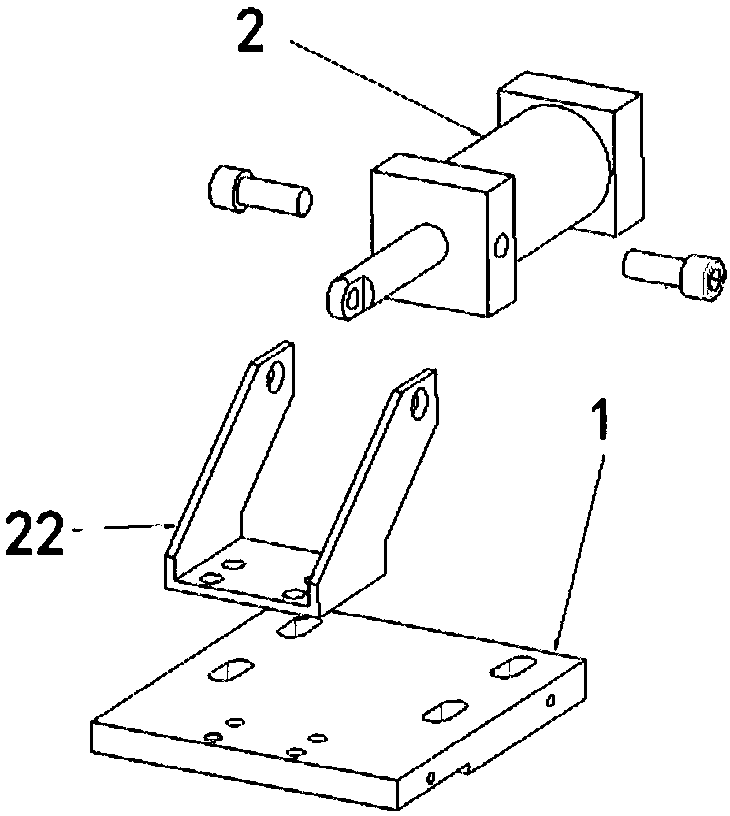

[0034] A grounding device for a base plate of a high-voltage transformer, comprising a tooling base plate 1, a cylinder 2, and a swing grounding mechanism, the tooling base plate 1 is a conductive metal plate, the main body of the cylinder 2 is fixedly connected to the tooling base plate 1, and one end of the swing mechanism is rotationally connected to the tooling base plate 1 , the other end is provided with a grounding copper column 4, the grounding copper column 4 is connected with a grounding wire, the output shaft of the cylinder 2 is rotationally connected with the middle part of the swing mechanism through the connecting rod 5,

[0035] When in use, the high-voltage transformer bottom plate is placed on the tooling bottom plate 1, the output shaft of the cylinder 2 moves, and the swing grounding mechanism is driven to swing through the connecting rod 5, so that the grounding copper column 4 is in contact with the tooling bottom plate 1, and the high-voltage transformer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com