Real-time monitoring system for inside view field and temperature of rotary hearth furnace and control method

A real-time monitoring and rotary hearth furnace technology, applied in the direction of furnace, charge, furnace type, etc., can solve the problems of inability to ensure production stability, inability to effectively adjust the smelting process, and inability to obtain the spatial temperature distribution of the furnace bottom material layer, etc., to achieve The effects of online and intelligent, reduced energy consumption, and data integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

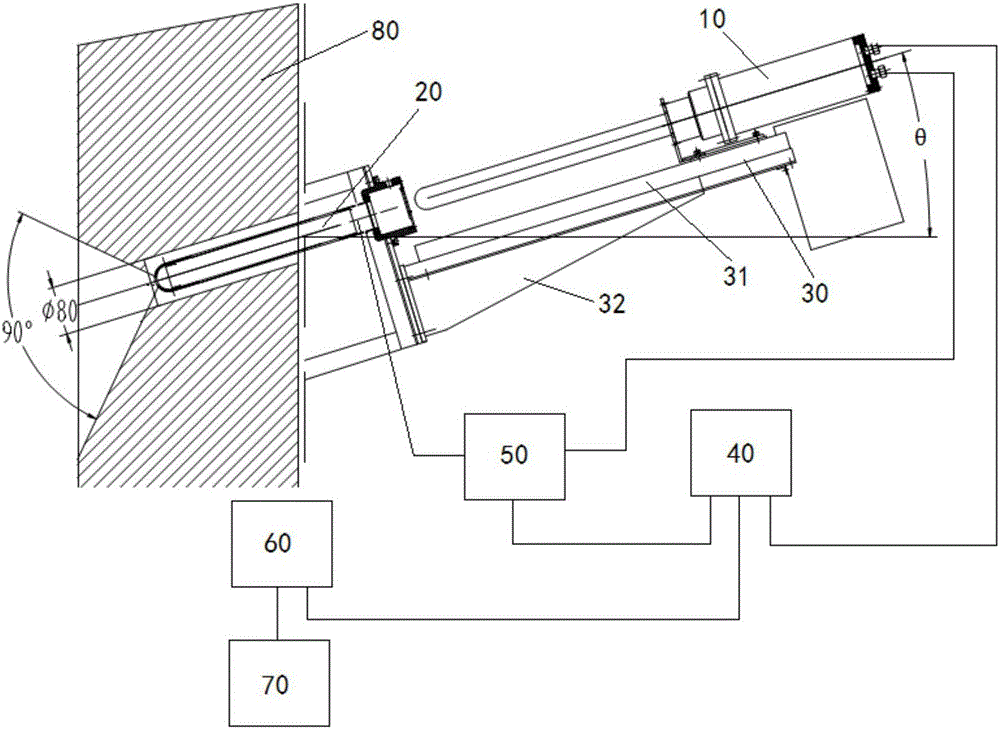

[0010] see figure 1 and figure 2 , a real-time monitoring system for field of view and temperature in a rotary hearth furnace according to the present invention, comprising a high-temperature imaging temperature measuring probe 10, an outer protective sleeve 20, and a pneumatic device for controlling the high-temperature imaging temperature measuring probe 10 to enter and exit the outer protective sleeve 20 Advance and retreat device 30 , electric control cabinet 40 , air source box 50 , controller 60 and image temperature display 70 . The outer protective sleeve 20 is arranged in the furnace wall 80 of the rotary hearth furnace for protecting the high temperature imaging temperature measuring probe 10 and can be connected by welding or bolts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com