Holding element and function assembly with same

A technology for maintaining components and functional components, applied in the direction of connecting components, mechanical equipment, etc., can solve problems such as shortened mold life, poor component quality, and increased molding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

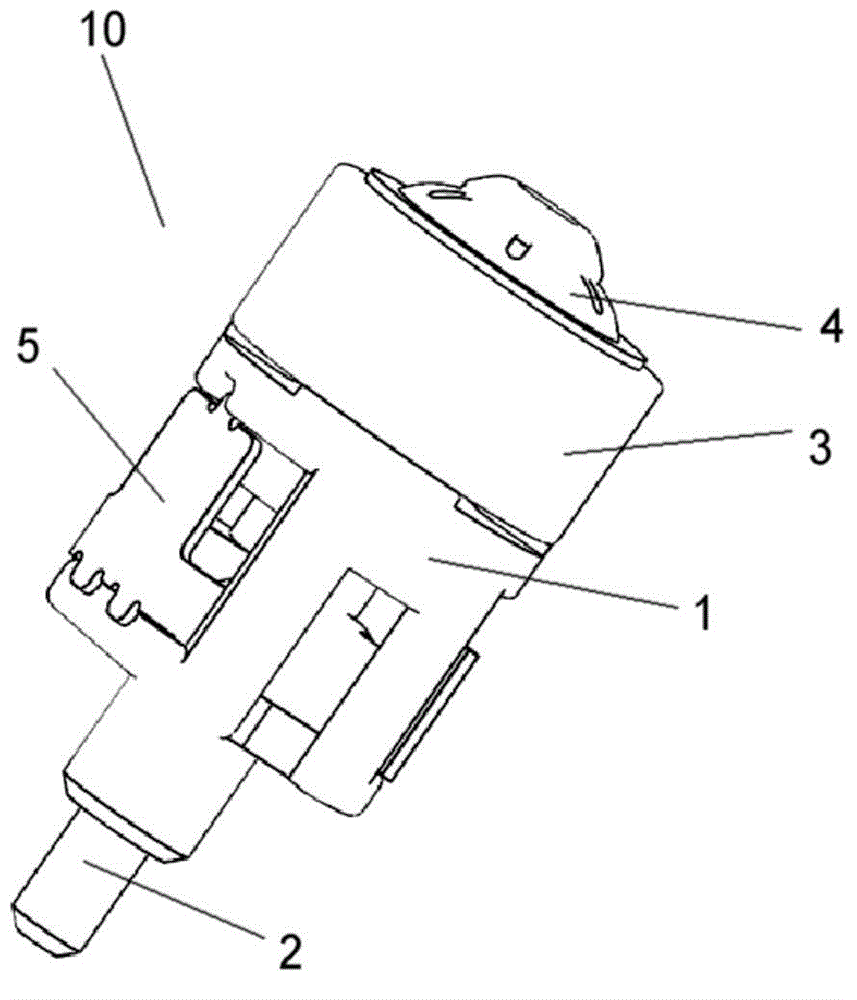

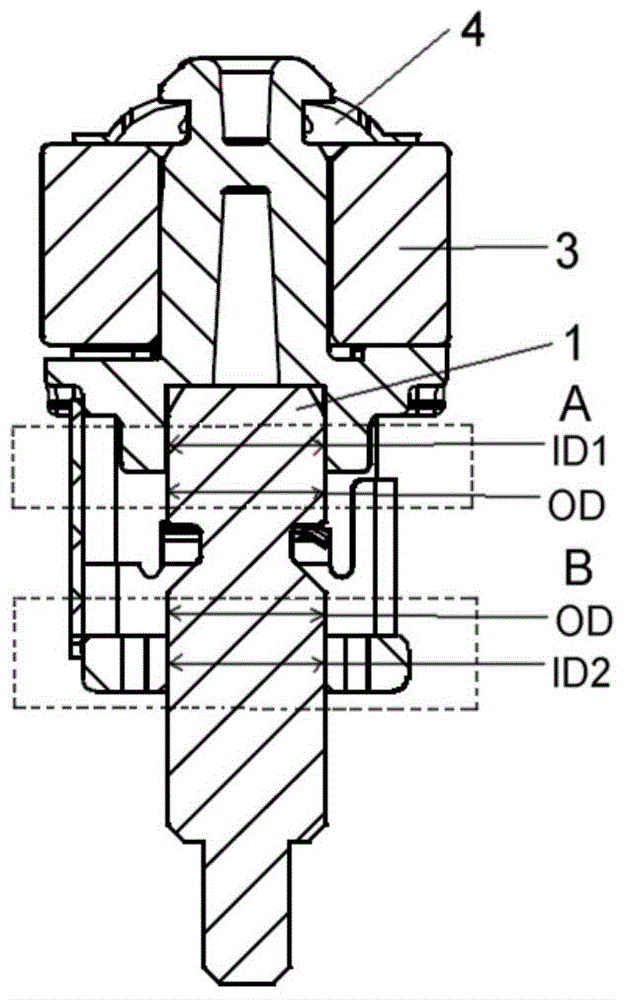

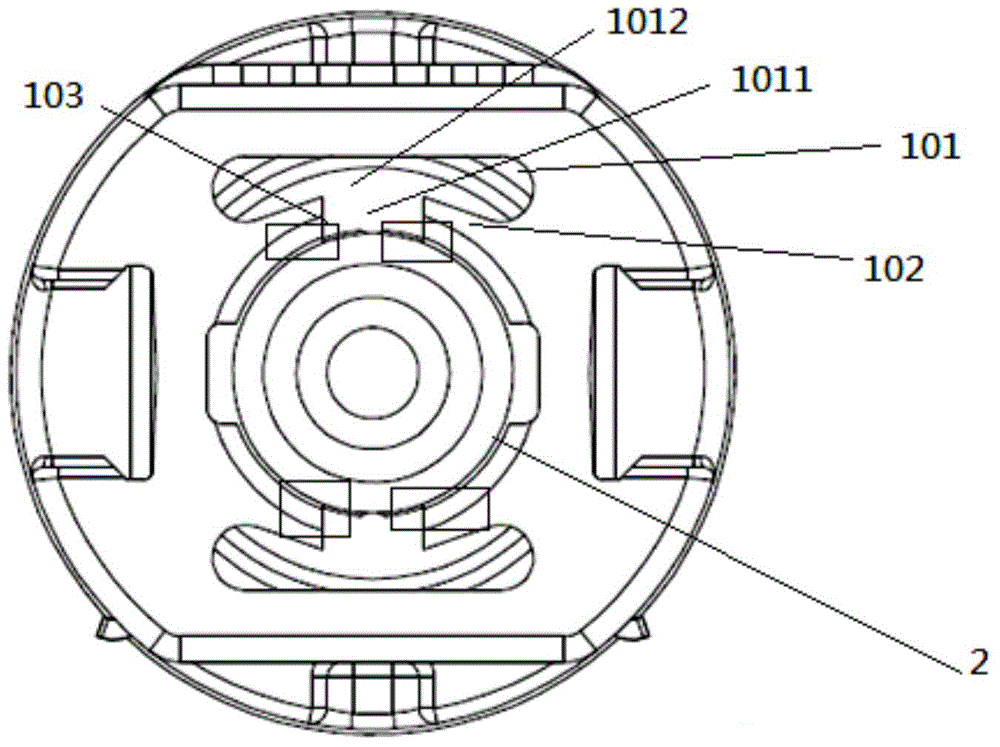

[0023] figure 1 and figure 2 The assembly of the functional assembly 10 on the shaft 2 is shown. The functional assembly 10 can comprise a holding element 1 , a functional part 3 , a holding clip 4 and an axial locking mechanism 5 . Wherein, when the functional component 10 is used as a part of a non-contact magnetic induction sensor, the functional component is a magnetic component, and the functional component 3 is a magnet, preferably a ring magnet. In this case, the holding element can have a bearing for carrying the functional component 3 . The functional part 3 carried on the holding element can be fixed on the holding element 1 by means of holding clips 4 covering the magnets. The holding element 1 can comprise a receptacle for being slipped on the shaft 2 . Along the socketing direction of socketing the holding element 1 on the shaft, the accommodating part may successively include a positioning area A and a clamping area B, through the positioning area A and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com