Novel volute centrifugal fan provided with permanent-magnet brushless motor system

A technology of permanent magnet brushless motor and centrifugal fan, applied in the direction of machine/engine, casing/cover/support, electromechanical device, etc., can solve the problems of shortened life, low heat dissipation efficiency, increased trouble, etc., to prolong the service life , the effect of speeding up heat dissipation and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

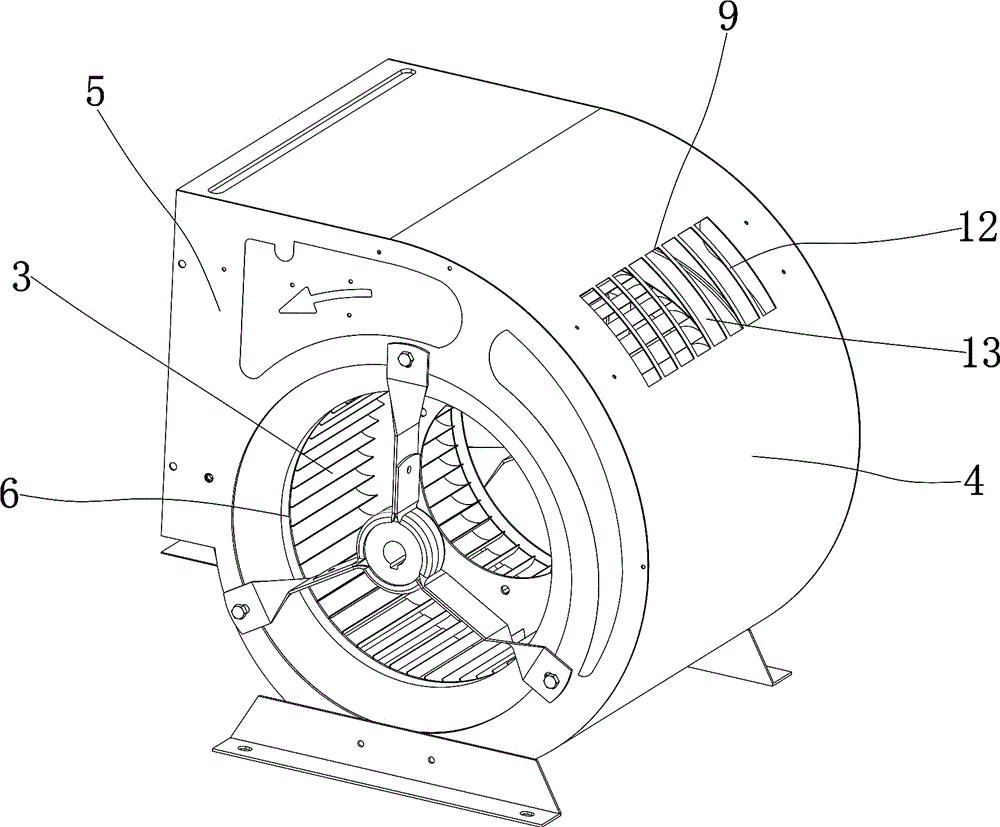

[0019] see Figure 1 to Figure 4 , the present invention provides a novel volute centrifugal fan with a permanent magnet brushless motor system, including a volute 1, an outer rotor motor 2 erected in the volute 1, and an impeller 3 outside the outer rotor motor 2, the impeller 3 is located in the volute 1, and the impeller 3 is connected with the outer rotor motor 2. The volute 1 is composed of a volute plate 4 and side plates 5 located on both sides of the volute plate. The side plates 5 on both sides are provided with air inlets 6. The volute 1 One side is provided with an air outlet 7, and an air duct is formed between the volute 1 and the impeller 3; the center position of the air outlet 7 is a horizontal plane 8, and the part of the worm plate 4 on the horizontal plane 8 is provided with an opening 9; The opening 9 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com