Composite spring damper capable of pre-setting initial rigidity

A composite spring and initial stiffness technology, applied in the field of damping devices containing composite springs, can solve the problems of waste of resources, reduce the cost of shock absorption, cannot change the initial stiffness of the damper, etc., and achieve the effect of reducing the length and reducing the cost of vibration isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

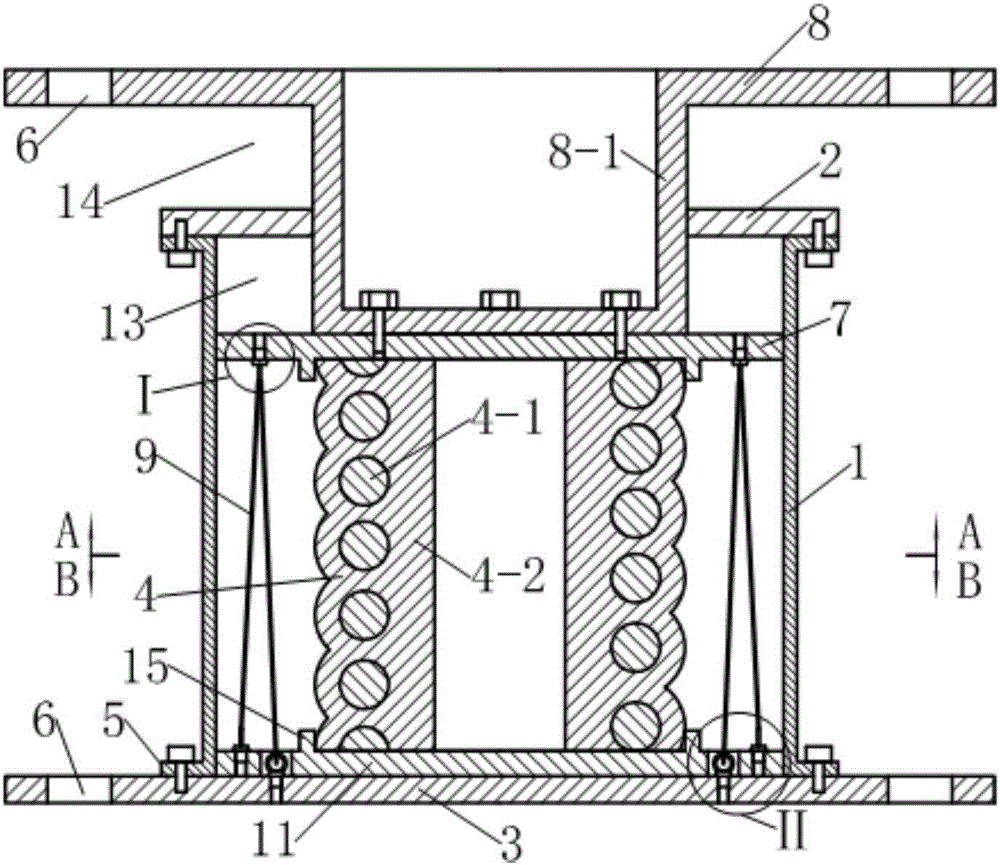

[0040] see Figure 1~5 , the damper described in this example is a vertical shock-isolation device (also known as a vertical shock-isolation support) for building anti-seismic, which includes a guide sleeve 1, a first end cover 2, a second end cover 3 , Composite spring 4 and back pressure device.

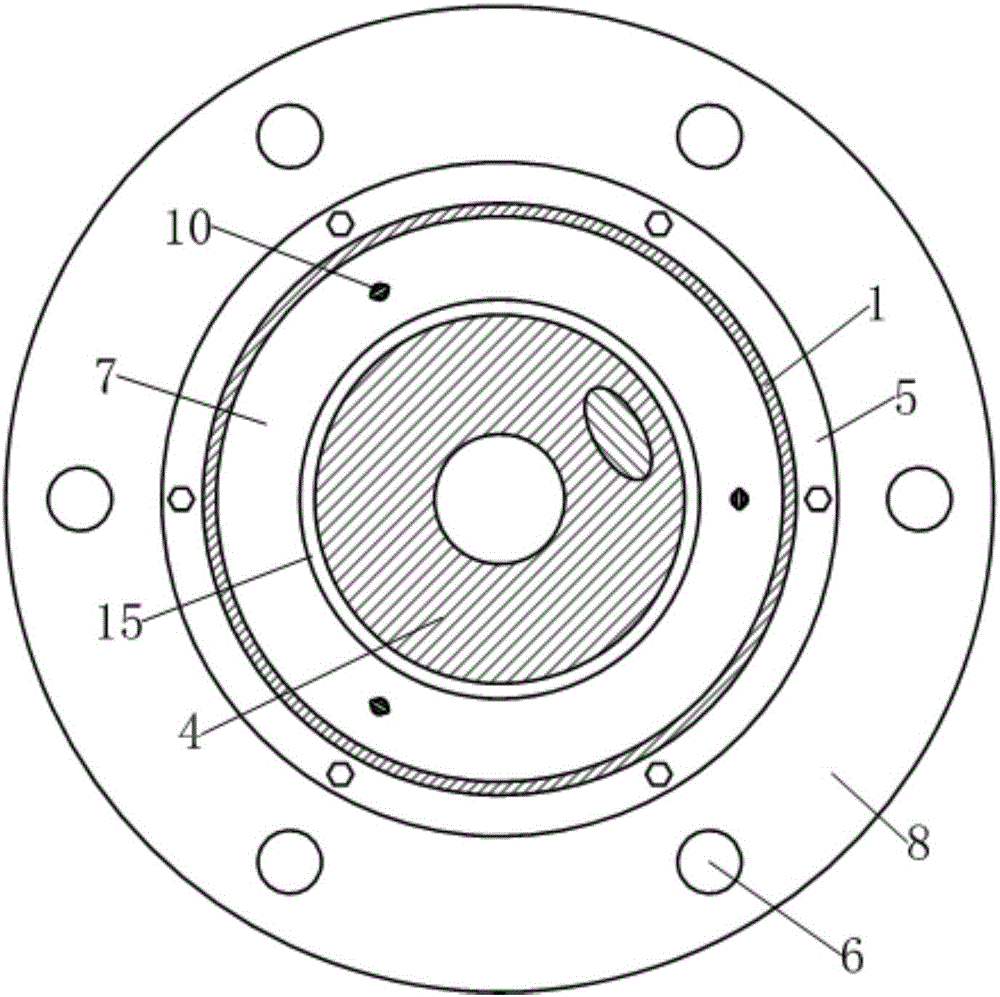

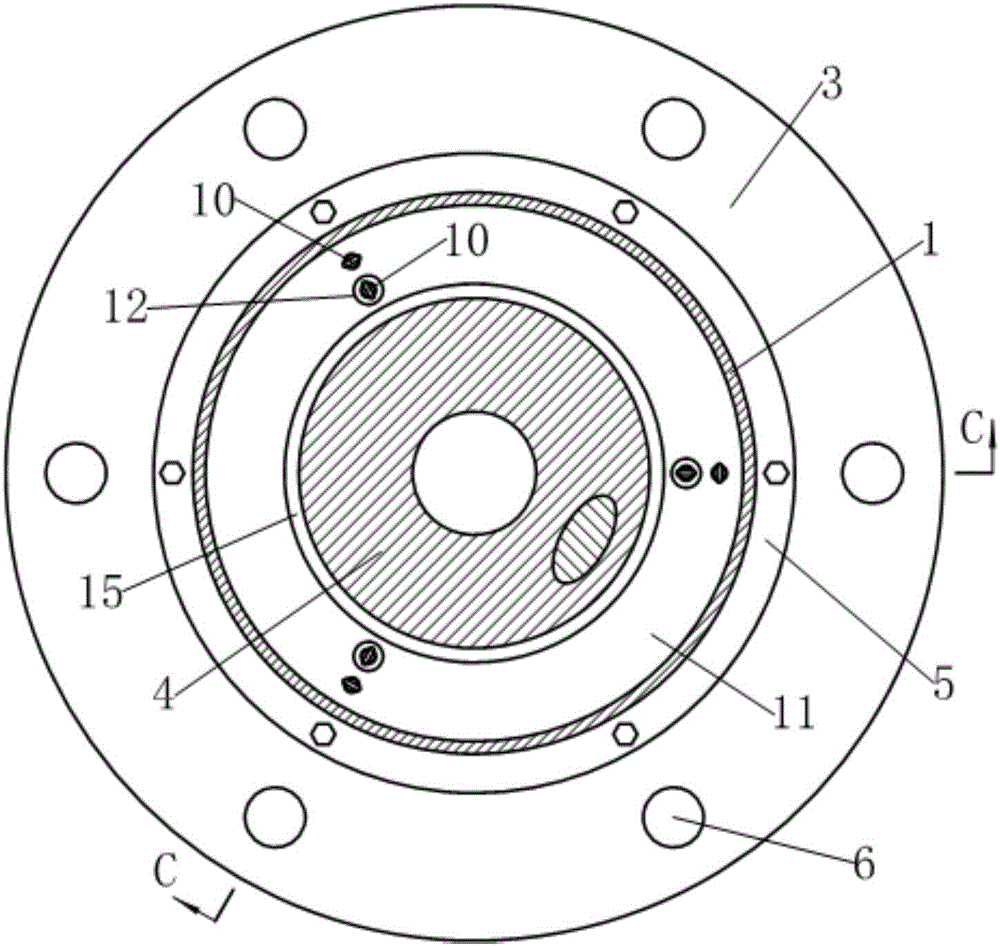

[0041] see Figure 1~3 , the guide sleeve 1 is in the shape of a circular tube, and its two ends extend radially outward to form a flange 5 . The first end cover 2 is connected to the flange 5 on the upper end of the guide sleeve 1, and the center is provided with a guide hole; the second end cover 3 is disc-shaped, and the surrounding edges are provided with mounting holes 6. The guide sleeve 1 is fixed on the middle part of its upper surface by the flange plate 5 provided at the lower end.

[0042] see Figure 1~3 , the driving member is composed of a dynamic pressure plate 7 and an upper connecting plate 8, wherein the edge of the upper connecting plate 8 is provided with a m...

example 2

[0055] see Figure 6-11 , the damper described in this example is also a vertical shock-isolation device for building anti-seismic, and on the basis of example 1, the following improvements are mainly made: (1) the pre-compressed steel wire rope 9 is increased by three to four; (2) replace the eye screw 10 as the wire rope changing element with a U-shaped member 17; (3) replace the eye screw 10 at the other end of the fixed preloaded wire rope 9 with a wire rope self-locking anchor 16; (4 ) thicken the middle part of the second end cover 3 and bulge upwards to form an inverted washbasin shape, so as to install the wire rope self-locking anchor 16; (5) correspondingly change the described back pressure device to:

[0056] The anti-pressure device consists of four pre-compressed steel wire ropes 9, four U-shaped members 17 as wire rope direction-changing elements, a floating counter-pressure steel plate 11, four eyebolts 10 for fixing one end of the pre-compressed steel wire rop...

example 3

[0065] see Figures 12 to 14 , this example is a damper used for seismic reinforcement of building structures, the damper includes a guide sleeve 1, the two ends of the guide sleeve 1 are respectively fixed with a first end cover 2 and a second end cover 3, and a composite spring is arranged inside 4. A drive member extends from the center of the first end cover 2 at one end of the guide sleeve into the guide sleeve 1 and presses on the composite spring 4; wherein the drive member is composed of a dynamic pressure plate 7 and an integrated The first driving rod 18 is formed, and the end of the first driving rod 18 is provided with a connecting ring 18 - 1 threadedly butted together with it, and the connecting ring 18 - 1 is provided with a hinge hole 19 .

[0066] see Figure 12 , the outer side of the second end cover 3 is provided with a second drive rod 20 integrated with it, and the end of the second drive rod 20 is provided with a hinged hole 19, and the dynamic pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com