Basalt fiber reinforced foam base composite heat-preservation layer and producing method thereof

A technology of basalt fiber and basalt fiber cloth, applied in the field of basalt fiber-reinforced foam-based composite insulation layer and its manufacture, can solve the problems of not being suitable for large-scale production, unfavorable transportation and application, poor flame resistance, etc., and achieve a comfortable and quiet resting environment , Improve heat insulation and noise reduction, flame retardant performance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

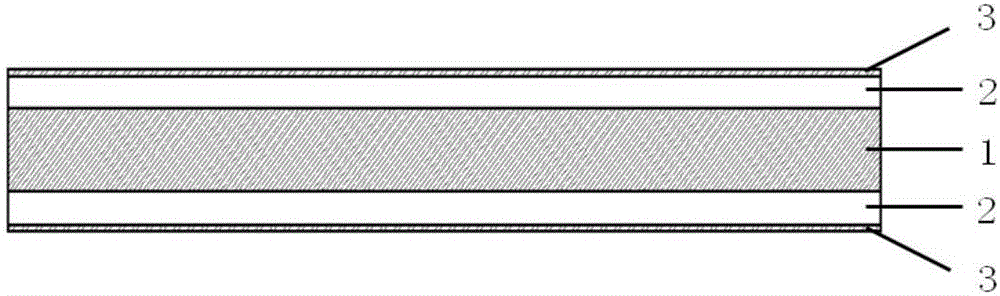

[0030] Such as figure 1 As shown, a basalt fiber reinforced foam-based composite insulation layer has a structure including a base plate 1, a compression plate 2, and a protective film 3.

[0031] The substrate 1 can be polyurethane foam, polystyrene foam, phenolic foam, etc. The foam matrix is light in weight and easy to transport.

[0032] The compressed board 2 is a laminated board with a certain thickness (thickness generally not exceeding 5mm) made by pressing basalt fiber cloth or basalt fiber needle felt. Because basalt fiber has the functions of high temperature resistance, flame retardancy, noise reduction and corrosion resistance, it can effectively isolate light during use, keep the indoor temperature within the comfortable range of human body, reduce the transmission of noise, and maintain a quiet rest indoors environment. When a fire occurs,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com