Novel propelling mechanism with quick-return characteristic

A propulsion mechanism, a new type of technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of complex control, low production efficiency, inconvenient maintenance, etc., and achieve the effect of improving transmission efficiency, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

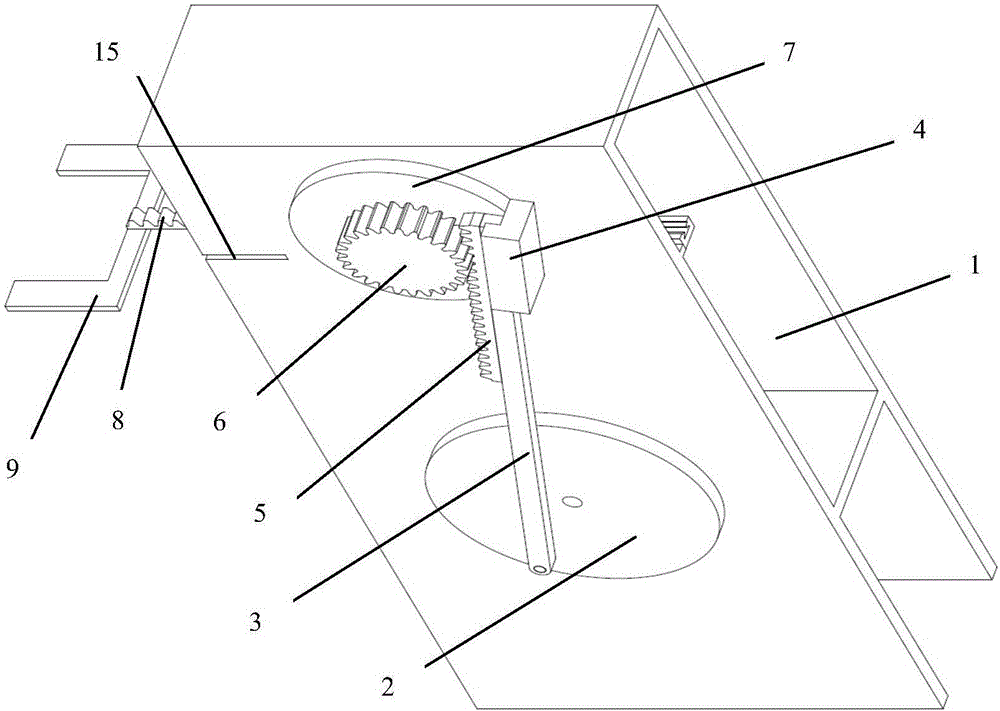

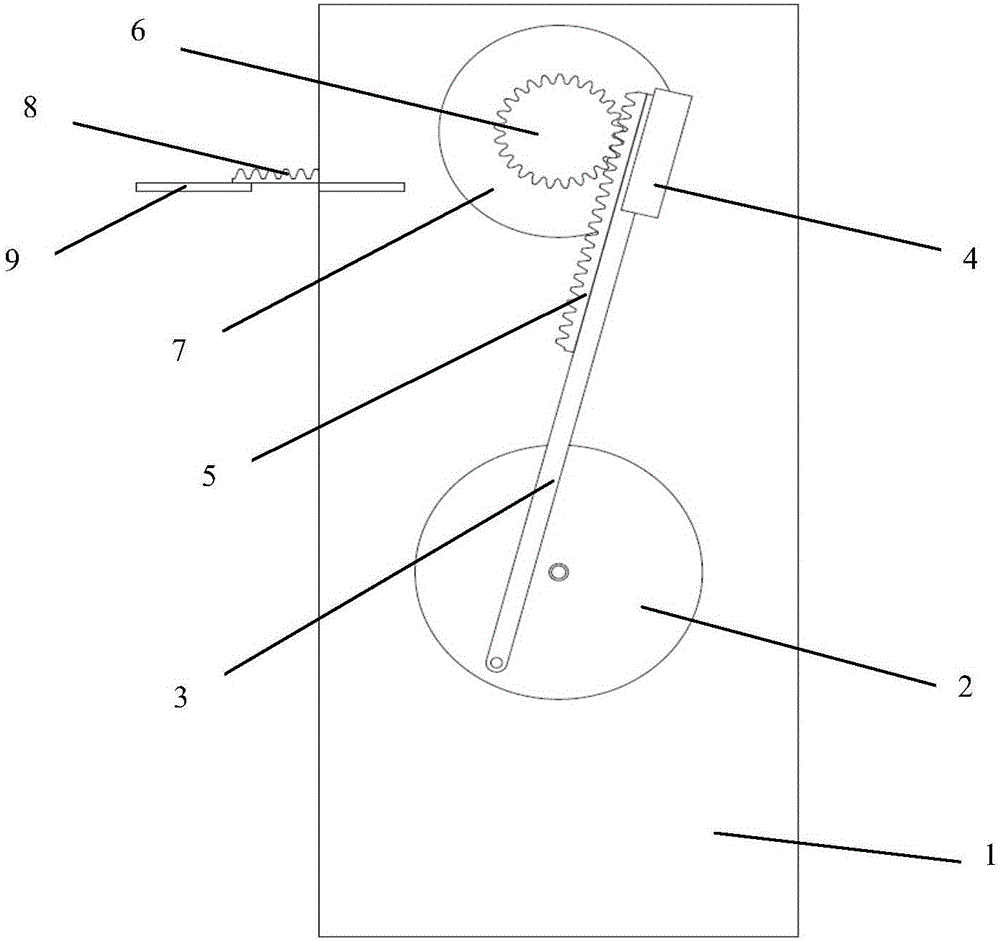

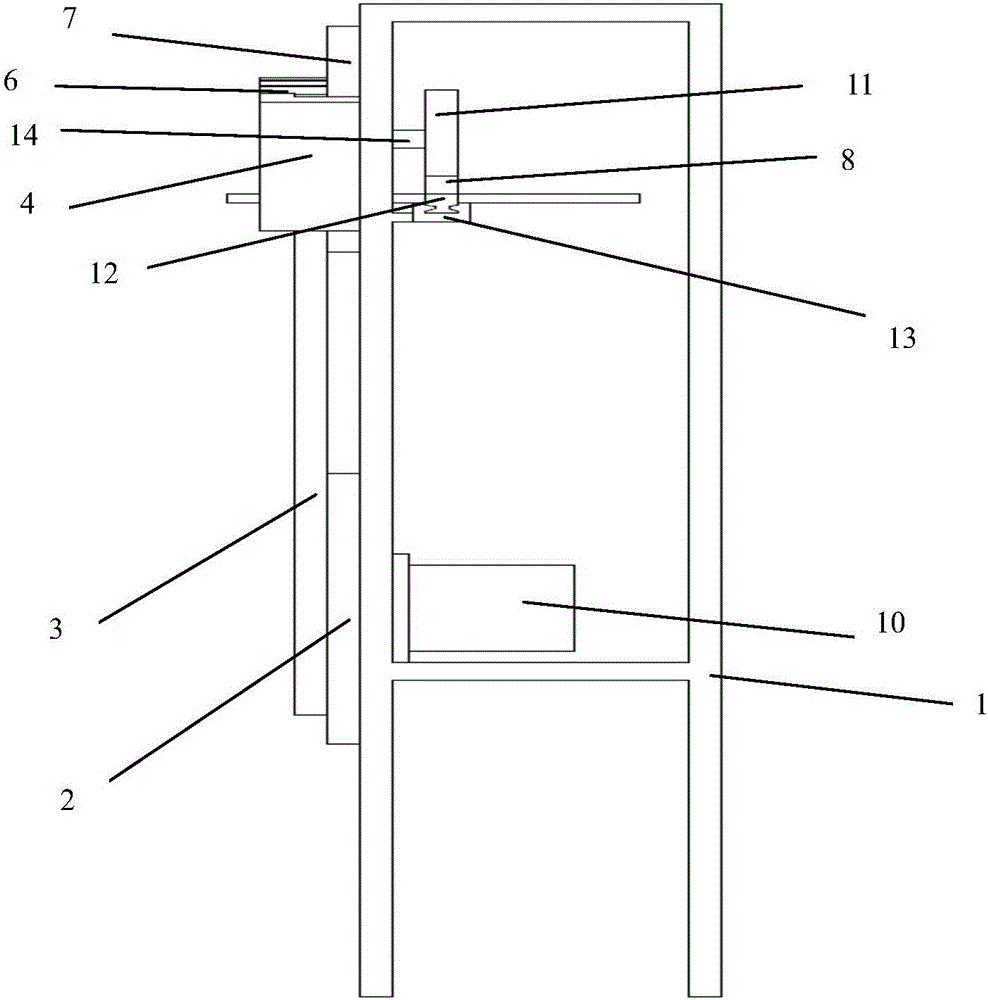

[0025] combine figure 1 , 2 , 3, a novel propulsion mechanism with quick return characteristics, including a frame 1, a motor 10, a lower disc 2, a connecting rod slider 3, a guide rail 4, a gear 6, a gear 2 11, and a propulsion gear 8 , rotating gear 5 and upper disc 7;

[0026] The frame 1 is inverted U-shaped, and a motor 10 is installed on the inner wall of one side of the frame 1; the output shaft of the motor 10 is connected with the input shaft of the lower disc 2; above, and the lower disk 2 is placed on the outer wall of the frame 1 side where the motor 10 is installed; the lower disk 2 is connected to one end of the connecting rod slider 3 through a rotating pair; One end is equipped with a rotating ruler bar 5; the rotating ruler bar 5 is meshed with the gear one 6;

[0027] Described gear one 6 is installed on the upper disk 7, and upper disk 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com