Double-rope traction monorail crane system

A monorail crane and rope traction technology, which is applied in the field of coal mine transportation system, can solve the problems that tractors cannot meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

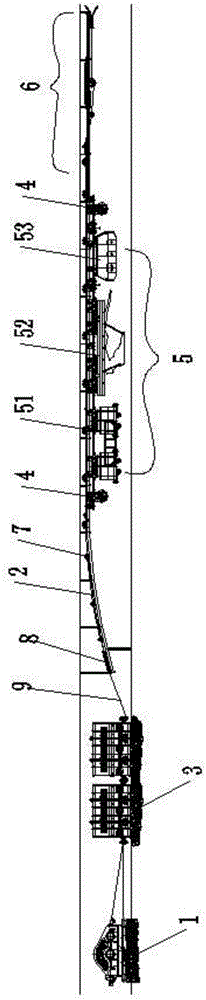

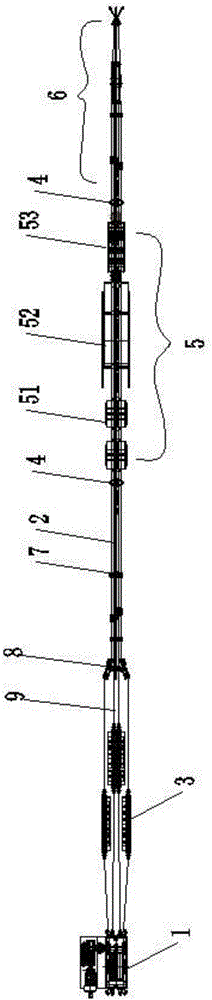

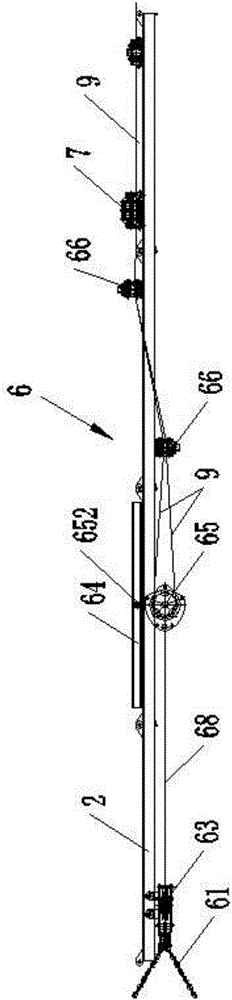

[0031] see Figure 1-15 As shown, a double-rope traction monorail crane system includes a power system 1, a tensioning device 3, a track 2, a traction head system 4, a transportation system 5, a tail wheel system 6, a double-rope pressing wheel set 7, and a rope guide The sheave set 8 and two traction wire ropes 9, the track 3 are fixedly connected to the upper part of the mine, the transport system 5 is mobile connected to the track 2, and the front and rear parts of the transport system 5 have traction head systems 4, The traction head system 4 is also connected to the track 2 in a mobile manner, and the track 2 is fixedly connected with a plurality of double-rope pressing wheel groups 7, and the rope receiving and guiding wheel group 8 is fixedly connected to the front end of the track 3. The two traction wire ropes 9 It starts from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com