Motor shell water-cooling structure

A motor casing and water-cooling technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of difficult process, difficult control, easy to produce cracks, etc., and achieve good sealing performance and firm fixation , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

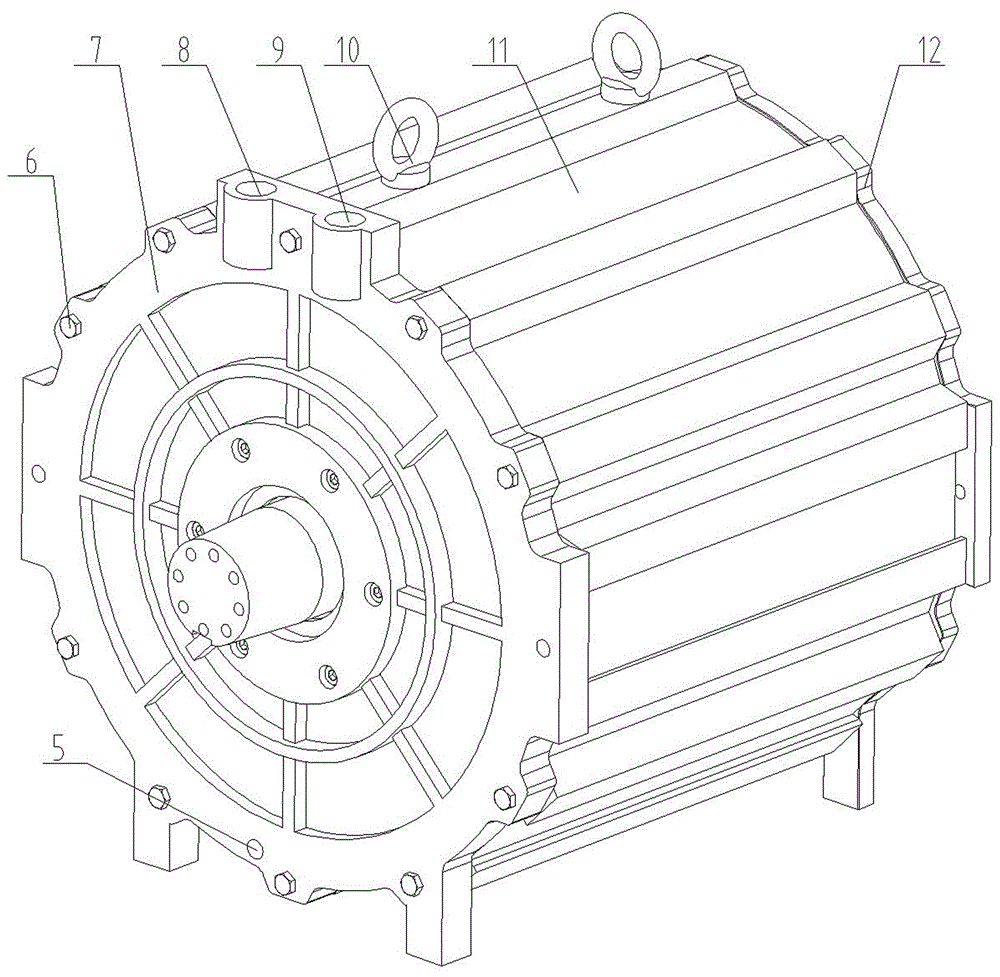

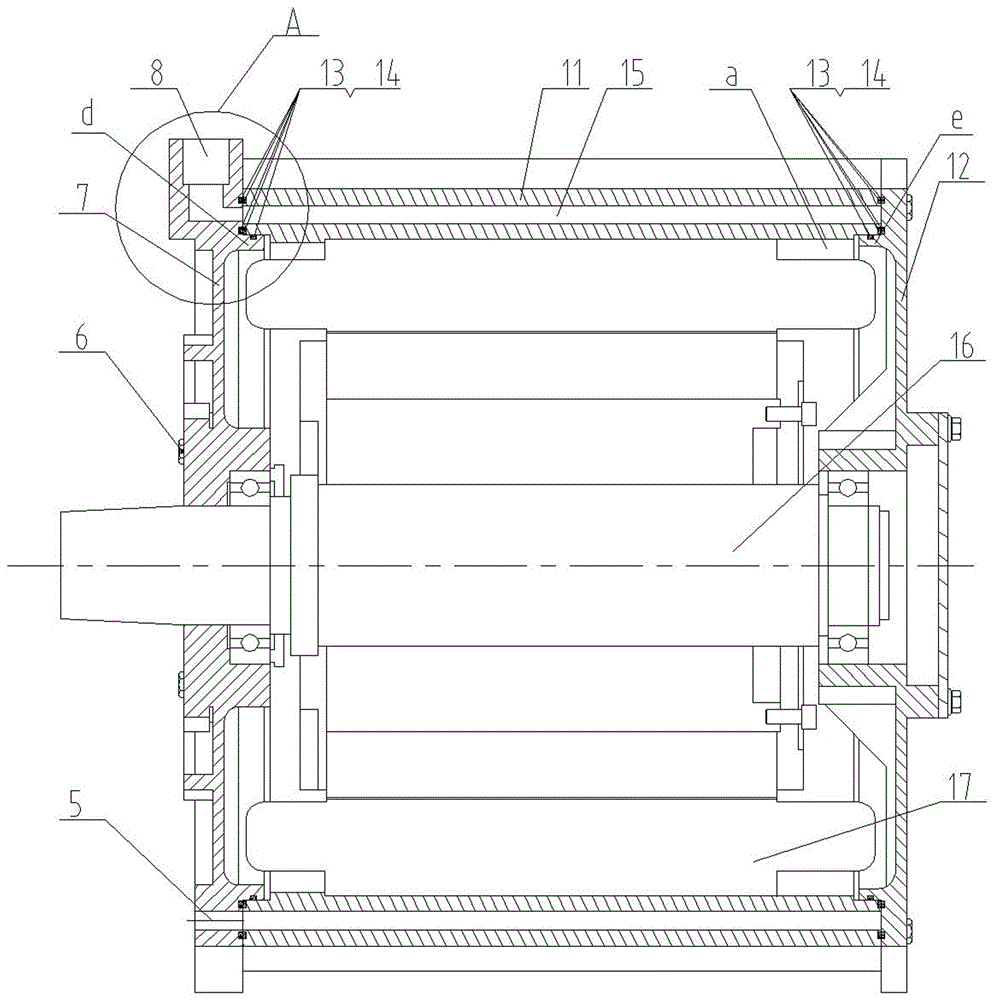

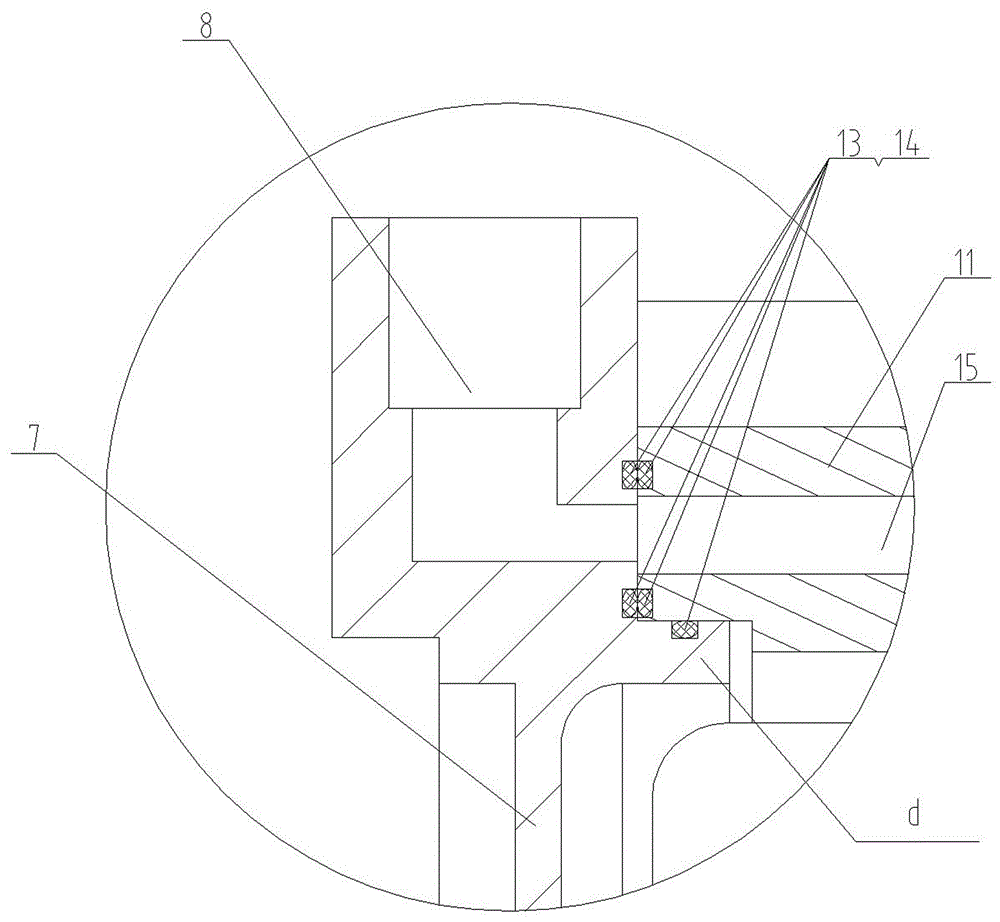

[0023] The present invention includes a front end cover 7, a machine base 11 with a suspension ring 10 in the middle for a perforation a of a stator 17 and a rotor 16, and a rear end cover 12. The special feature lies in the base along the periphery of the machine base 11. The wall is provided with a number of axial water guide holes 15 which are even numbers, and the rear end of each pair of adjacent axial water guide holes 15 at the rear end of the base 11 is provided with a rear wall connecting the rear ends of the adjacent axial water guide holes 15. end groove b, the front end of the base 11 is staggered between each pair of axial water guide holes 15 adjacent to the rear end of the base 11 and each pair of axial water guide holes 15 adjacent to the front end, except for a pair of adjacent front ends Outside the axial water guide hole 15 of the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com