Operation method of an electric stripping device for protecting wire cores of waste cables

A technology of waste cable and operation method, which is applied in the direction of cable installation, cable installation device, equipment for dismantling/armored cable, etc. The peeling effect is good, the quality is guaranteed, and the effect of reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

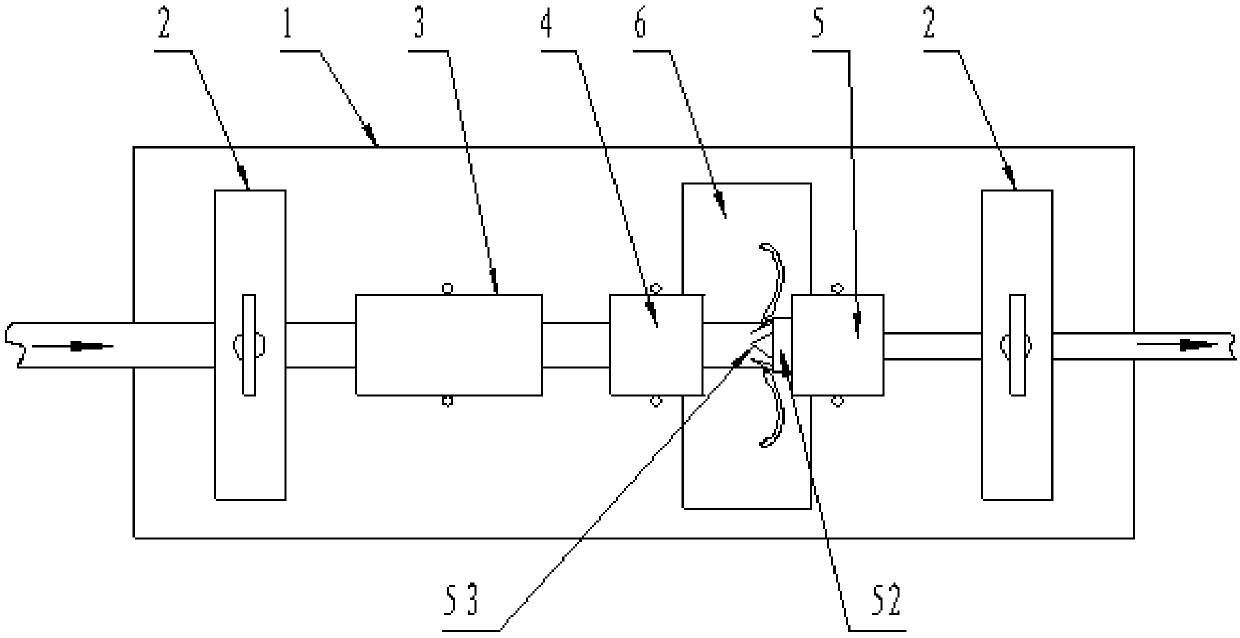

[0030] The two ends of the console 1 are provided with clamping mechanisms 2, and between the two clamping mechanisms 2, a heater 3, a skin-cutting mechanism 4, a skin-removing mechanism 5, a skin-cutting mechanism 4 and a skin-removing mechanism 5 are sequentially arranged between the two clamping mechanisms 2 along the running direction of the cable An insulating layer collection hole 6 is arranged between them;

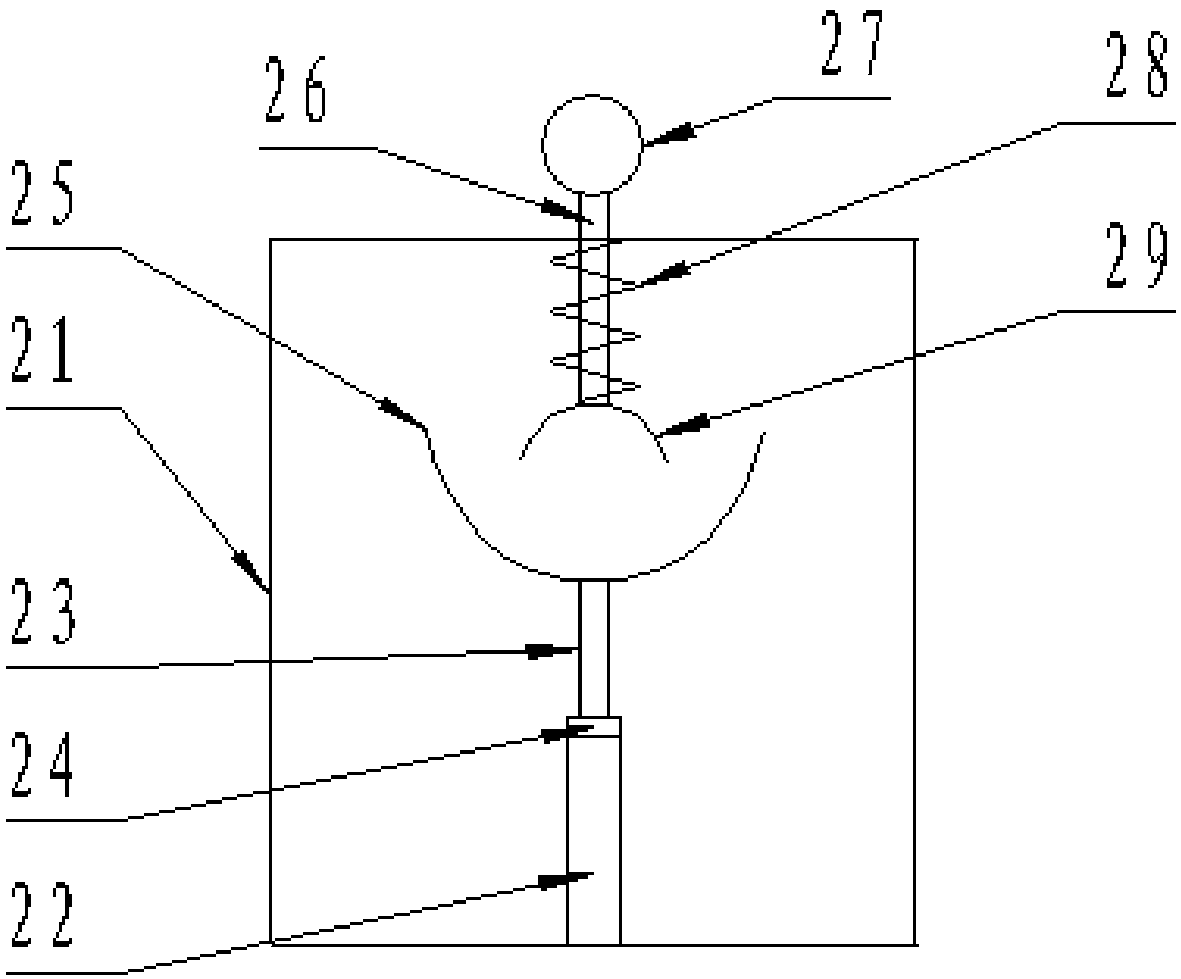

[0031] The structure of the clamping mechanism 2 is as follows: the main rod 22 is arranged in the lower middle part of the fixed frame 21, the telescopic rod 23 is arranged in the main rod 22, the outer periphery of the telescopic rod 23 above the main rod 22 is provided with a locking ring 24, and the upper end of the telescopic rod 23 is provided with a lower clip. Sheet 25, connecting rod 26 is set in the reserved hole of fixed frame 21 top center, and connecting rod 26 upper end is provided with draw ring 27, and lower end is provided with upper clip 29, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com