Sealing gasket convenient to install, of plate heat exchanger

A plate heat exchanger and gasket technology, which is applied to heat exchanger sealing devices, heat exchange equipment, lighting and heating equipment, etc. and other problems, to achieve the effect of safe operation and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

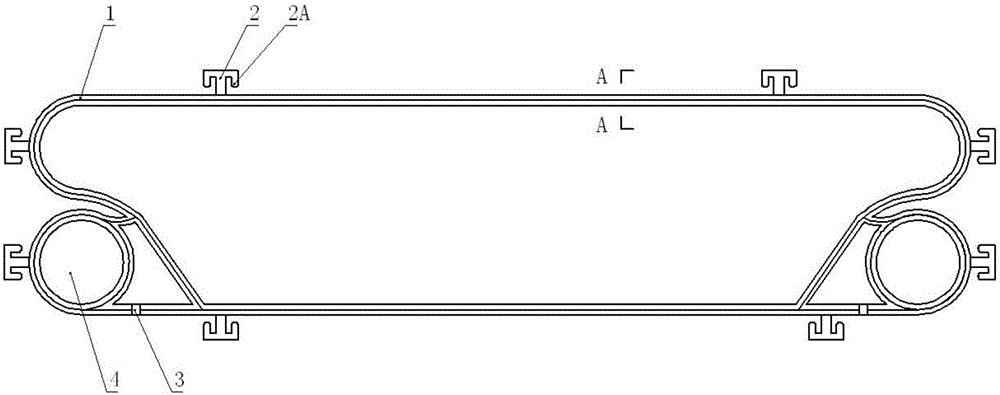

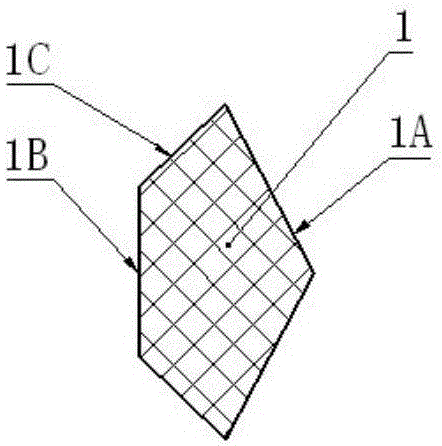

[0018] A plate heat exchanger gasket for easy installation, such as figure 1 As shown, it includes a body 1 and a positioning part 2. The outer edge of the body is integrally formed with a plurality of positioning parts at intervals. The positioning part is a T-shaped structure. The two ends of the positioning part are integrally extended to the body and formed with protrusions. 2A, the gasket can be quickly installed and positioned on the plate (not shown in the figure) through the protrusion, and the left and right ends of the body are formed with corner holes 4 .

[0019] In this embodiment, eight positioning parts are installed at intervals. During the production process of the heat exchanger, the gasket is placed on the front of the plate, and then the protrusion of the positioning part is installed on the back of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com