Steel pipe necking and welded hollow sphere connection joint

A technology for connecting nodes and hollow spheres, which is used in buildings, building structures, etc., can solve the problems of seismic damage of bolted ball joints and large size of welded hollow spheres, achieve reasonable and reliable structural design, improve bearing capacity, and reduce welding seams. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

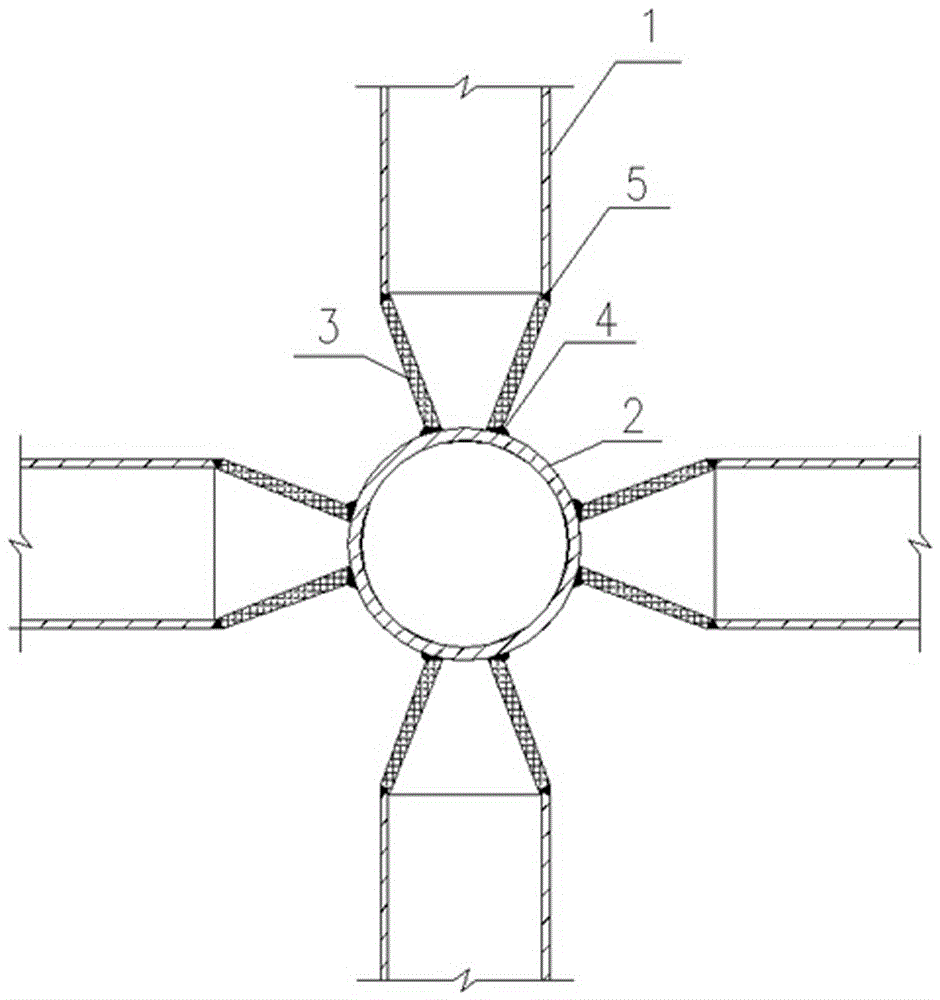

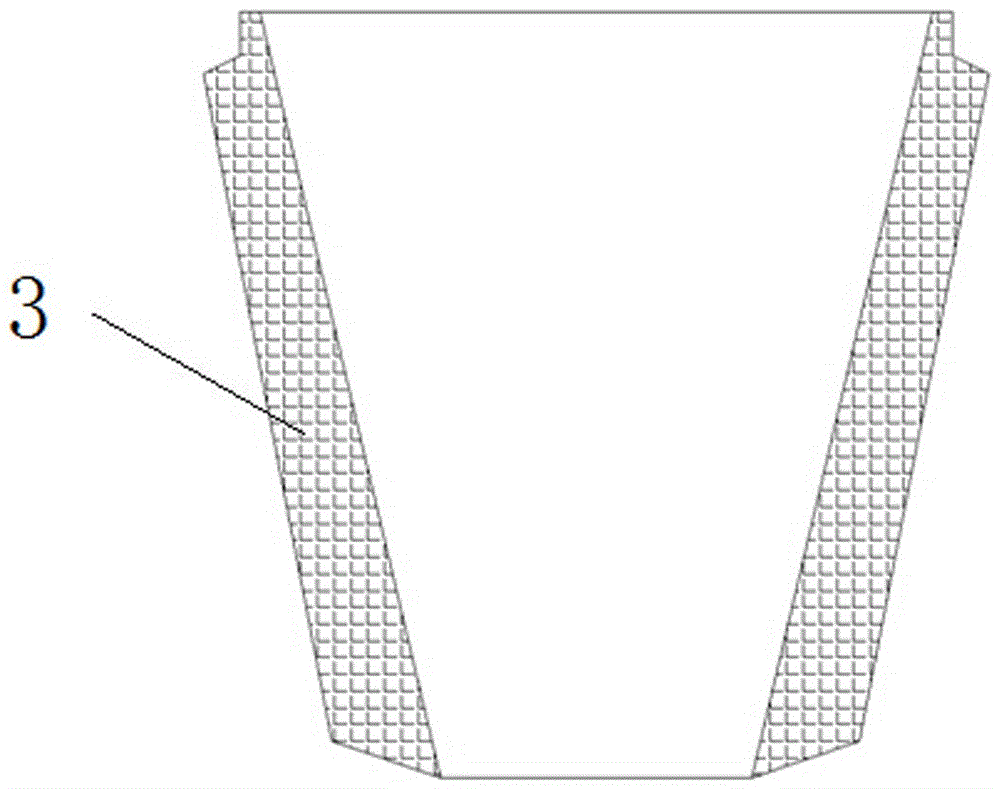

[0012] The connection node between steel pipe shrinkage and welded hollow ball, including steel pipe 1, welded hollow ball 2 and steel tapered pipe 3, a butt weld 5 connecting the two is arranged between one end of steel tapered pipe 3 and steel pipe 1, and steel tapered pipe 3 There is a butt weld I4 connected between the other end and the welded hollow ball 2, and the wall thickness of the steel tapered tube 3 gradually increases along the side of the welded hollow ball 2.

[0013] In the specific implementation process, the steel pipe 1 and the steel tapered pipe 3 are connected as one in the factory through the butt weld 5, and the steel tapered pipe 3 and the welded hollow ball 2 are assembled together through the butt weld 4 during field operations; the steel tapered pipe 3 The inclination angle and thickness range are determined according to the bearing capacity and connection structure, and the diameter of the small head of the steel tapered pipe 3 is determined accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com