Filling tube for producing a column of filling material in the ground as well as device and method related thereto

A filling material and filling pipe technology, which can be used in soil protection, sheet pile walls, buildings, etc., can solve problems such as problems with filling pipes, and achieve the effect of improving service life, large degrees of freedom, and good structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

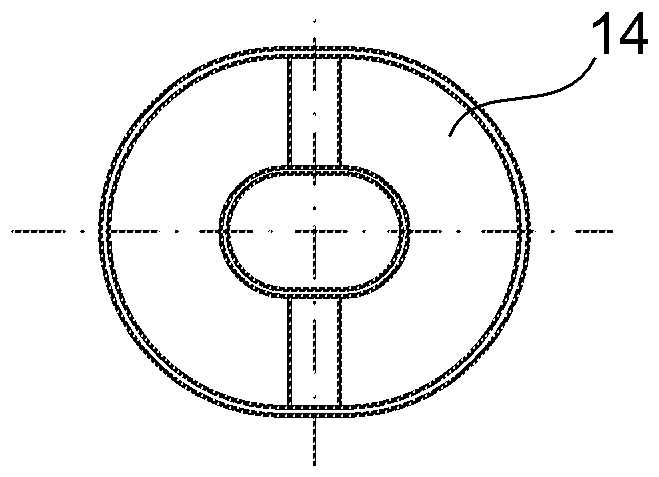

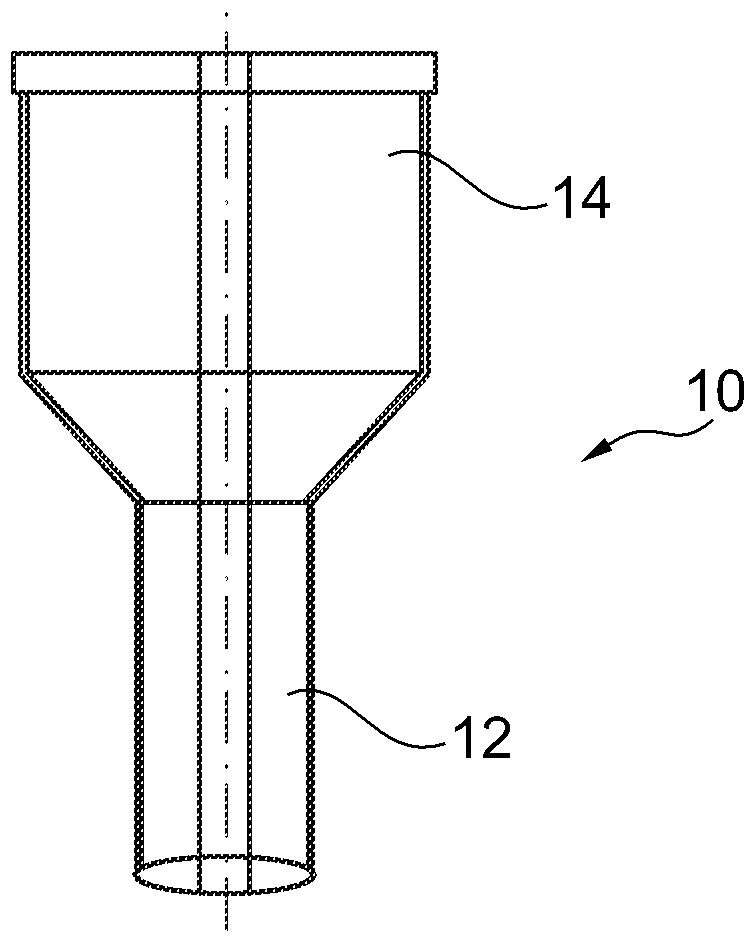

[0040] From Figures 1a to 1e The first filling tube 10 according to the invention is seen in partial section and oblique view. The first filling tube 10 according to the invention has a tube body 12 which has an oval tube cross-section. In the upper end region of the tubular body 12 there is provided a funnel region 14 which widens conically upwards and has an oval receiving section. Funnel region 14 is used to receive and fill fill material to form a column of fill material. Specifically, the fill material is a pourable medium such as sand, gravel, lime, concrete, and the like.

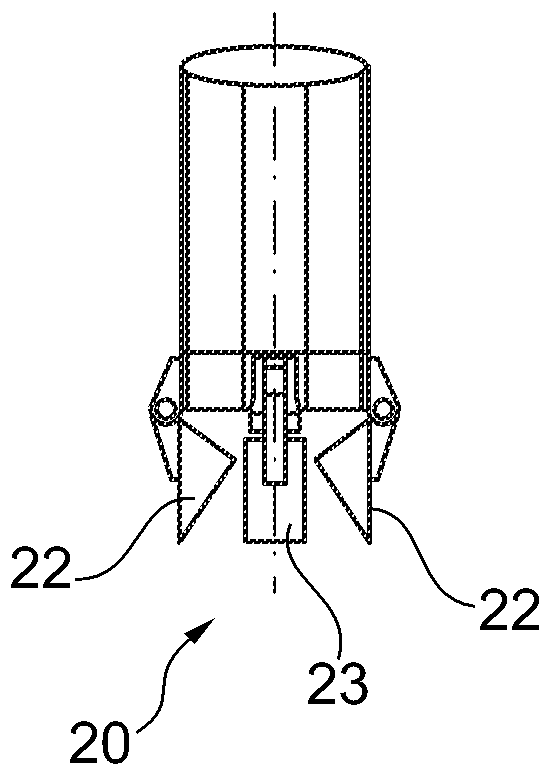

[0041] At the lower end of the tubular body 12 a closing means 20 with two closing flaps 22 is arranged. The closing flaps 22 are each coupled to the tubular body 12 via a pivot joint 26 . The pivot joints 26 each have a joint pin 28 aligned transversely with respect to the pipe axis and about which a respective shell-shaped closure flap 22 is pivotable.

[0042] In the central region of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com