Composite reinforced loess foundation and construction method thereof

A technology of composite geomembrane and loess, which is used in infrastructure engineering, soil protection, construction, etc., can solve problems such as loess foundation vibration and sink, and achieve the effects of controlling foundation deformation, improving water sensitivity, and enhancing foundation bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

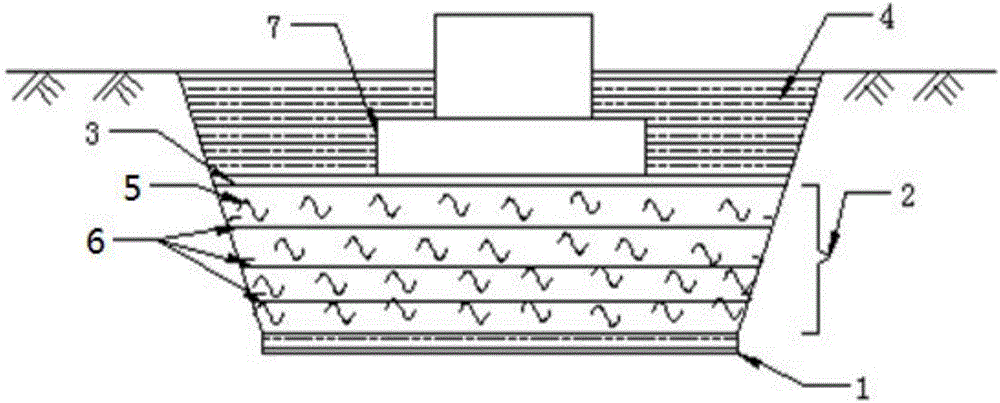

[0040] Embodiment 1 of the present invention provides a composite reinforced loess foundation. The foundation is composed of lime-soil cushion layer 1, composite reinforced loess replacement soil layer 2, composite geomembrane 3 and lime-soil backfill soil layer 4 from bottom to top. The loess replacement soil layer 2 is evenly mixed with glass fiber 5, and the composite reinforced loess replacement soil layer 2 is evenly laid with three layers of bidirectional geogrids 6 along the horizontal direction. Specifically, the bidirectional geogrids 6 laid are made of steel Plastic geogrid, steel wire is installed inside the steel-plastic geogrid, and the mass per unit area of bidirectional geogrid 6 is 520g / m 2 , the side length of the transverse mesh is 40mm, the side length of the longitudinal mesh is 40mm, the longitudinal tensile strength is 26.09KN / m, the transverse tensile strength is 25.91KN / m, the longitudinal elongation is 12.3%, and the transverse elongation is 12.8% . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com