Internal sizing agent emulsion and preparation method and application of same

A technology of sizing and emulsion in slurry, which is applied in the field of emulsion, can solve the problems of reduced water resistance and achieve the effect of improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

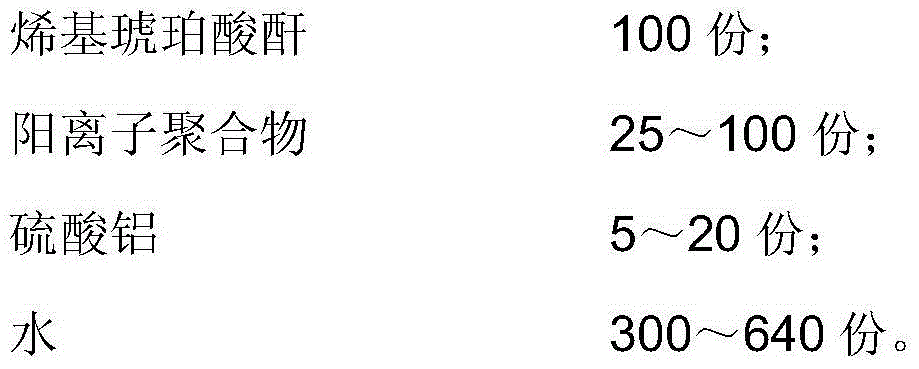

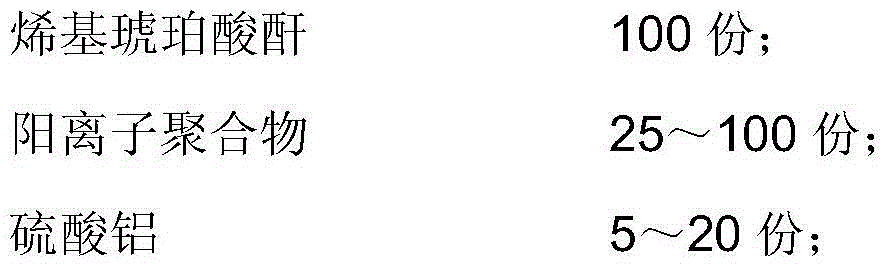

[0037] The invention provides a method for preparing a sizing agent emulsion in a slurry, which is characterized in that the cationic polymer and water are mixed, alkenyl succinic anhydride (ASA) is added, stirred homogeneously, and aluminum sulfate is added to obtain the slurry sizing agent emulsion. Sizing agent emulsion;

[0038] Wherein, the cationic polymer is an aqueous dispersion formed by copolymerization of cationic monomers, (methyl)styrene, and silane. In this preparation method, 2,2'-azobis(amidinopropyl) disalt The acid salt is used as an initiator, and the solution is prepared by radical solution polymerization using the above-mentioned mixed monomers, and then a surfactant is added to obtain the required cationic polymer.

[0039] In a preferred embodiment of the present invention, the preparation method of the slurry internal sizing agent emulsion comprises:

[0040] Step 1: Mix the cationic polymer and water at 50-70°C with a stirring speed of 8000-10000rpm / m...

Embodiment 1

[0070] 1. Preparation method of cationic polymer

[0071] a) Mix 5 grams of styrene and 5 grams of vinyltriisopropoxysilane to make a mixed monomer, and set aside.

[0072] b) Mix 90 grams of dimethylaminoethyl methacrylate monochloromethane quaternary ammonium with 10 grams of deionized water, dissolve completely, and set aside.

[0073] c) Mix 0.2 g of 2,2'-azobis(amidinopropyl) dihydrochloride and 10 g of deionized water, dissolve completely, and set aside.

[0074] d) Add 133.5 grams of deionized water into the reactor, raise the temperature to 95°C, add the aqueous solution of 2,2'-azobis(amidinopropyl) dihydrochloride in step c), and then add dropwise at 95°C Step a) Mix the monomers with the cationic monomer solution in b) for 1 hour.

[0075] e) Incubate at 95°C for 1 hour. Add 2g of cetyltrimethylammonium chloride at the end of the heat preservation, cool down to 25°C, and filter through a 100-mesh sieve. The obtained cationic polymer had a weight solid content of...

Embodiment 2

[0080] 1. Preparation method of cationic polymer

[0081] a) Mix 10 grams of methyl styrene and 10 grams of γ-methacryloxypropyltrimethoxysilane to make a mixed monomer, and set aside.

[0082] b) Mix 80 grams of dimethylaminoethyl methacrylate benzyl quaternary ammonium chloride with 10 grams of deionized water, dissolve completely, and set aside.

[0083] c) Mix 2 g of 2,2'-azobis(amidinopropyl) dihydrochloride and 10 g of deionized water, dissolve completely, and set aside.

[0084] d) Add 428 grams of deionized water into the reactor, raise the temperature to 95°C, add the aqueous solution of 2,2'-azobis(amidinopropyl) dihydrochloride in step c), and then drop it at 95°C Add the mixed monomer in step a) and the cationic monomer solution in b) for 3 hours.

[0085] e) Incubate at 60°C for 2 hours. At the end of the heat preservation, add 10 g of octadecyltrimethylammonium chloride, cool down to 25° C., and filter through a 100-mesh sieve. The obtained cationic polymer h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com