Ultrasonic washing machine

A technology of ultrasonic waves and washing machines, applied in the field of ultrasonic waves, can solve the problems of small shock force and friction force in vibration transmission, difficult to thoroughly clean stubborn dirt, and low ultrasonic intensity, etc., to achieve high impact force and friction force, good washing effect, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

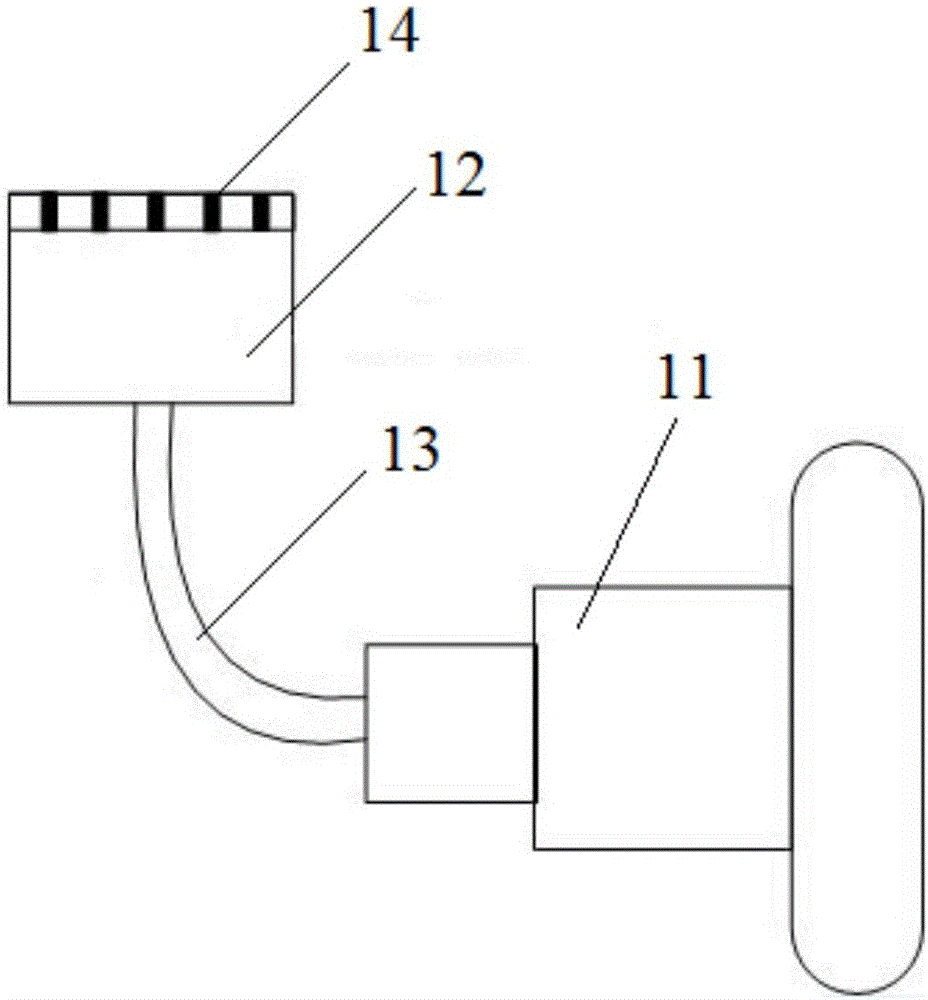

[0033] In the embodiment of the present invention, the ultrasonic transducer in the ultrasonic emitting device in the ultrasonic washing machine generates high-frequency ultrasonic waves, and the ultrasonic waves are used to instantly burst the bubbles generated by the gas emitter in the cleaning liquid, and the friction and impact generated by the bursting of the bubbles Power can remove stains on the object to be cleaned.

[0034] In the embodiment of the present invention, the cleaning liquid may be water or other possible liquids, and the type of the cleaning liquid is not limited in the embodiment of the present invention.

[0035] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

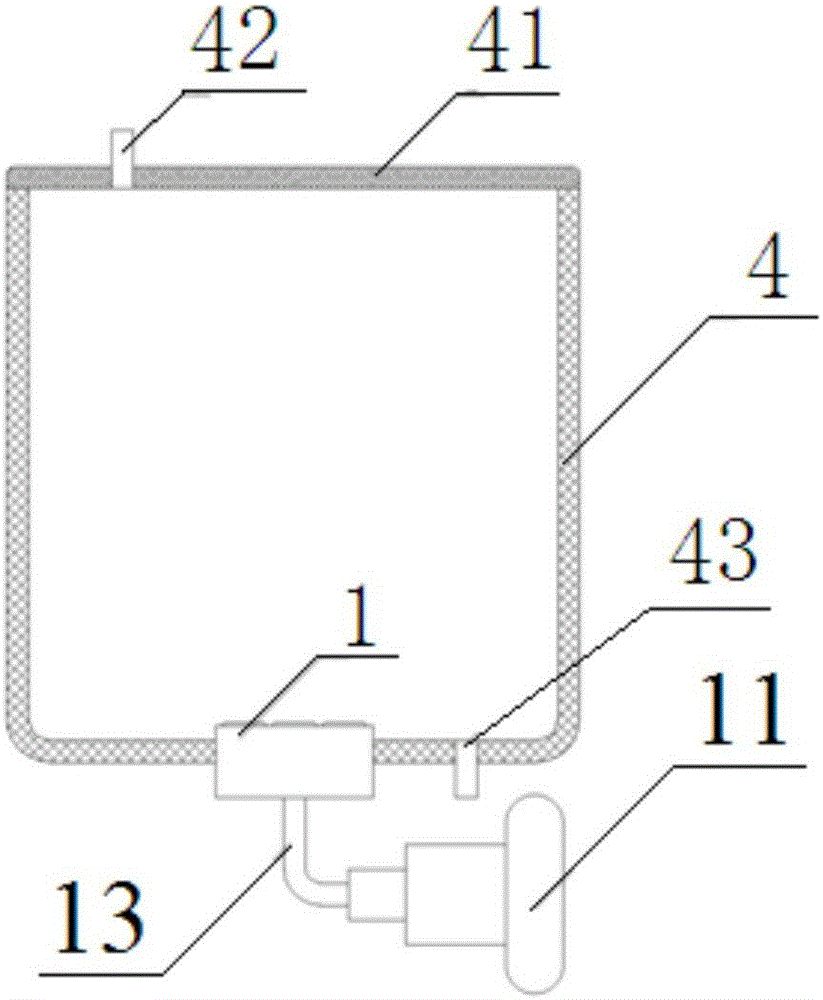

[0036] See figure 1 An embodiment of the present invention provides an ultrasonic washing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com