Copper powder recovery device

A recovery device and technology for copper powder, applied in rotary drum furnaces, crucible furnaces, furnaces, etc., can solve the problems of difficulty in practical use, increase production costs, damage to natural environment, etc., and achieve simple structure, not easy to block, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

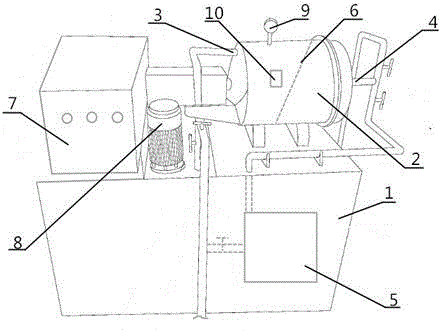

[0012] Embodiment 1: A kind of copper powder recycling device

[0013] Such as figure 1 As shown, the present invention provides a copper powder recovery device, comprising a base 1 and a filter cartridge 2 arranged on the base 1; one end of the filter cartridge 2 is a waste liquid inlet 3, and the other end is a waste liquid outlet 4; A filter 5 is arranged in the base 1, one end of the filter 5 is connected to the waste liquid outlet 4 through a pipeline, and the other end is connected to the waste liquid inlet 3 through a pipeline; the filter cartridge 2 is inclined at 5 degrees from the horizontal ground, so An inclined filter screen 6 is arranged in the filter cartridge 2; a control box 7 and a drive motor 8 are also arranged on the base 1. The position of the waste liquid inlet 3 is higher than the waste liquid outlet 4 . The filter cartridge 2 is provided with a pressure gauge 9 . The filter cartridge 2 is also provided with an observation window 10 . The copper pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com