U-shaped groove surface quenching inductor

A surface quenching and U-shaped groove technology, which is applied in the field of quenching sensors, can solve the problems that small-diameter U-shaped grooves cannot be quenched, U-shaped grooves cannot be quenched, etc., and achieve the effects of simple structure, uniform hardness distribution, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

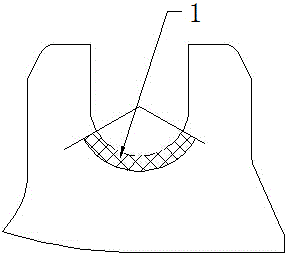

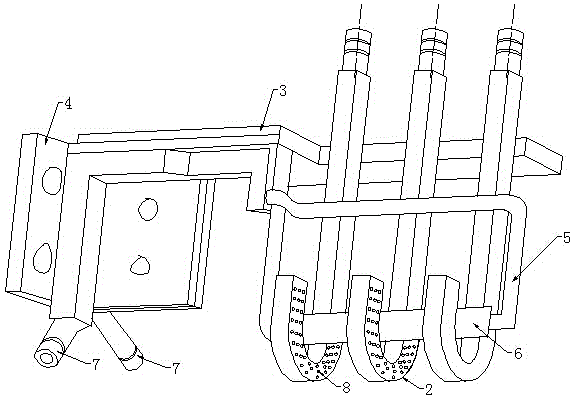

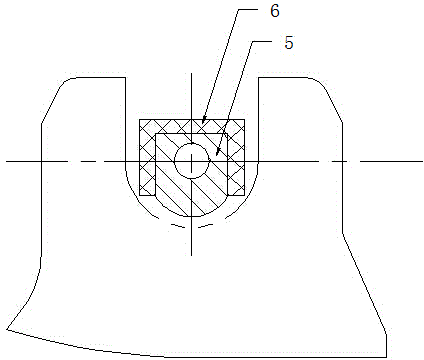

[0014] Such as figure 2 As shown, a U-shaped groove surface quenching inductor includes a set of induction heating parts, cooling parts 2 and support frame 3, the induction heating part and a plurality of cooling parts 2 are fixed on the support frame 3 by screws, and the support frame 3 consists of Made of insulating material; the induction heating part is composed of a bus bar 4, an effective coil 5 and a set of magnetizers 6, the two ends of the effective coil 5 are connected to the bus bar 4 by welding, and the effective coil 5 is connected to the transformer equipment through the bus bar 4 , the effective ring 5 is a variable cross-section structure with the section gradually becoming smaller along the length direction; the bottom of the U-shaped groove of the workpiece is arc-shaped, that is, the side of the effective ring 5 corresponding to the bottom of the U-shaped groove of the workpiece is an arc-shaped protrusion, and the effective ring 5 A cooling hole is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com