Efficient resource treatment and reuse system of waste water of hydrogen prepared by Texaco furnace coal

A coal-to-hydrogen and resource-based technology, applied in water/sewage treatment, oxidized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problems of difficult removal, high cost, and low benefit, and achieve reduced treatment cost, increase the carbon-nitrogen ratio, and reduce the effect of treatment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

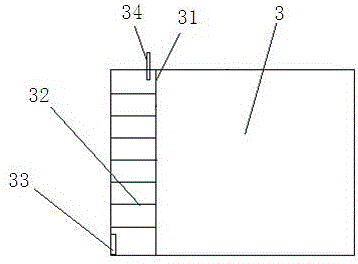

[0026] see figure 1 and figure 2 , in an embodiment of the present invention, a high-efficiency resource treatment and reuse system for Texaco furnace coal-to-hydrogen wastewater, the upper water outlet of the black water settling tank 1 is connected to Ca through the first drainage pump 15 2+ Lower water inlet of reaction sedimentation tank 2, Ca 2+ The upper water outlet of the reaction sedimentation tank 2 is connected to the lower water inlet of the MAP reaction sedimentation tank 3 through the second drainage pump 20, and the upper water outlet of the MAP reaction sedimentation tank 3 is connected to the lower water inlet of the anaerobic treatment unit 4 through the third drainage pump 30 , the water outlet of the anaerobic treatment unit 4 is connected to the water inlet of the aerobic treatment unit 5 through the fourth drainage pump 35, the water outlet of the aerobic treatment unit 5 is connected to the water inlet of the secondary sedimentation tank 6, and the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com